Why HDPE Liners Fail: Common Causes and How to Prevent Them

HDPE geomembrane is a extensively relied on impermeable answer for containment structures in landfills, water reservoirs, wastewater therapy facilities, and industrial sites. Its sturdiness and chemical resistance make it a pinnacle preference for long-term environmental protection, however even amazing hdpe geo membrane can fail except suited care. Failures no longer solely compromise containment integrity however additionally lead to highly-priced repairs, environmental penalties, and venture downtime. This information explores the most frequent motives of HDPE liner failure, from set up blunders to environmental stressors, and outlines actionable prevention techniques to maximize the lifespan of hdpe geomembrane systems.

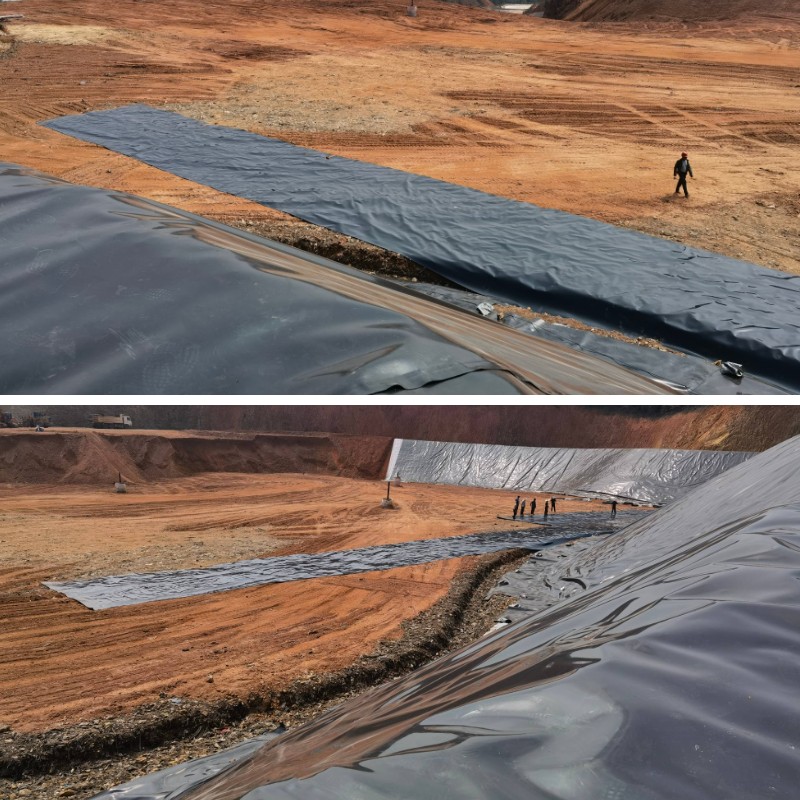

Poor Geomembrane Installation: The Leading Cause of Early Failure

Inadequate geomembrane set up is the major perpetrator in the back of untimely HDPE liner failures. Even the highest-grade hdpe geo membrane can't function as meant if mounted incorrectly. Common set up errors encompass flawed seam welding, insufficient floor preparation, and careless coping with of the membrane. Seam disasters are specifically problematic—if hdpe geomembrane sheets are now not welded with regular warmth and pressure, gaps structure that permit leaks. Surface practise oversights, such as leaving sharp particles or uneven terrain underneath the liner, can motive punctures or tears over time. Additionally, dragging or stretching hdpe geomembrane at some point of set up weakens the material, making it extra inclined to stress fractures. Working with licensed installers and following producer recommendations for geomembrane set up is fundamental to averting these pitfalls.

Environmental and Chemical Stressors

HDPE geomembrane is resistant to most chemicals, however severe environmental prerequisites and harsh resources can degrade the fabric over time. UV radiation from prolonged solar publicity breaks down the polymer shape of hdpe geo membrane, main to brittleness, cracking, and decreased tensile strength. This is mainly frequent in uncovered purposes except shielding coverings. Chemical degradation happens when hdpe geomembrane comes into contact with incompatible substances, such as robust oxidizers or sure solvents, which can soften, discolor, or weaken the liner. Temperature fluctuations additionally pose a risk—extreme warmth motives expansion, whilst freezing temperatures can make the cloth brittle, growing the probability of cracks. Mitigating these stressors includes the usage of UV-stabilized hdpe geomembrane, choosing chemical-resistant formulations for industrial applications, and including defensive layers to guard the liner from environmental extremes.

Physical Damage: Punctures, Tears, and Abrasion

Physical injury to hdpe geo membrane can show up in the course of installation, operation, or maintenance, main to instant or gradual failure. Punctures regularly end result from sharp objects like rocks, building equipment, or particles left below or on pinnacle of the liner. Tears may additionally structure due to immoderate anxiety in the course of geomembrane installation, floor movement, or heavy hundreds utilized at once to the liner. Abrasion from soil particles, tools traffic, or water float can put on down the floor of hdpe geomembrane over time, thinning the fabric and decreasing its durability. Preventing bodily injury requires thorough web site practise to dispose of sharp debris, the usage of shielding geotextile layers above and under the hdpe geomembrane, and limiting heavy gear get entry to to liner areas. Regular inspections additionally assist become aware of minor injury earlier than it escalates into essential failures.

Ground Movement and Settlement

Ground motion and contract are frequent motives of HDPE liner failure in web sites with unstable soil or altering terrain. When the floor shifts—whether due to erosion, subsidence, or seismic activity—the hdpe geo membrane is subjected to uneven stress. This stress can stretch, tear, or separate seams, compromising the liner’s integrity. For example, in landfill sites, ongoing waste agreement can pull the hdpe geomembrane taut, main to seam disasters or cloth fatigue. To stop this, suited web site geotechnical evaluation is necessary earlier than geomembrane set up to become aware of unstable areas. Engineers may also use reinforcement layers, such as geogrids, to distribute stress evenly throughout the hdpe geomembrane, or format the liner with flexibility to accommodate minor floor motion except damage.

Inadequate Maintenance and Inspection

Even with flawless geomembrane set up and extremely good hdpe geomembrane, neglecting upkeep and inspections can lead to sudden failures. Minor damage, such as small punctures or seam separations, can go overlooked and irritate over time, ensuing in massive leaks. Lack of everyday cleansing can purpose particles buildup, which traps moisture and quickens cloth degradation. Additionally, vegetation boom on or close to the hdpe geo membrane can puncture the liner as roots expand. Preventive protection consists of hobbies visible inspections, leak detection checks (such as vacuum or electrical tests), and on the spot restore of any recognized damage. Establishing a normal preservation agenda ensures that workable problems are addressed early, extending the lifespan of the HDPE liner system.

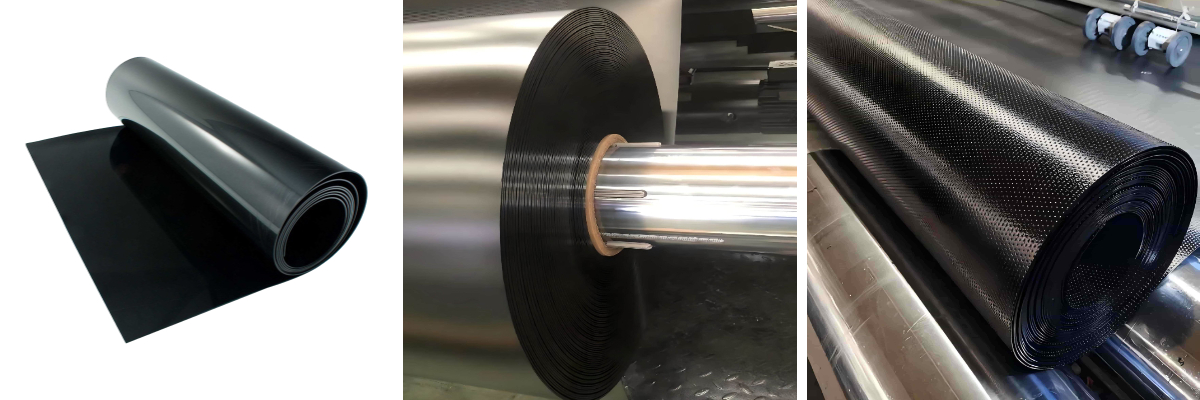

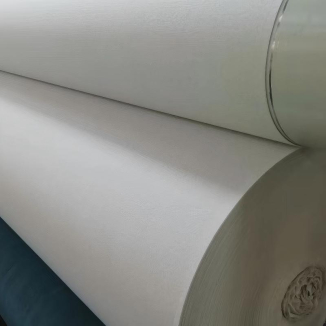

Material Defects and Substandard Products

While much less common, fabric defects and substandard hdpe geo membrane can lead to untimely failure. Defects might also encompass inconsistent thickness, impurities in the polymer, or insufficient UV stabilization. Substandard merchandise frequently fail to meet enterprise specs for tensile strength, chemical resistance, and durability, making them extra inclined to damage. To keep away from this, customers ought to supply hdpe geomembrane from legit suppliers who grant certification files verifying compliance with enterprise standards. Requesting cloth samples and conducting unbiased trying out can additionally make certain that the hdpe geomembrane meets mission requirements. Investing in super cloth upfront prevents steeply-priced screw ups and ensures long-term performance.

Prevention Strategies for Long-Lasting HDPE Liners

Preventing HDPE liner failure requires a proactive method that spans geomembrane installation, cloth selection, maintenance, and environmental management. Start by using choosing the proper hdpe geomembrane for the application—choose UV-stabilized or chemical-resistant formulations based totally on website conditions. Ensure geomembrane set up is carried out via licensed specialists the usage of acceptable tools and techniques, with rigorous seam checking out to confirm integrity. Prepare the web site completely to do away with sharp particles and stabilize the ground. Implement protecting measures, such as geotextile layers and UV covers, to protect the hdpe geo membrane from bodily harm and environmental stress. Establish a normal inspection and renovation schedule, such as leak detection checks and instantaneous repairs. By following these strategies, mission managers can reduce the danger of HDPE liner failure and maximize the lifespan of their containment systems.

Conclusion: Protecting Your HDPE Liner Investment

HDPE liner failure is frequently preventable, with most troubles tracing returned to avoidable errors in geomembrane installation, fabric selection, or maintenance. By perception the frequent causes—from bad set up to environmental stressors—and enforcing proactive prevention strategies, task managers can make sure their hdpe geomembrane structures supply dependable overall performance for decades. Investing in awesome hdpe geo membrane, licensed installation, and normal preservation is a long way greater low-cost than addressing disasters after they occur. Ultimately, a well-protected HDPE liner no longer solely safeguards the surroundings however additionally preserves assignment investments and avoids steeply-priced downtime and penalties.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province