UV Resistance and Chemical Stability: Essential Geocell Qualities for Outdoor Use

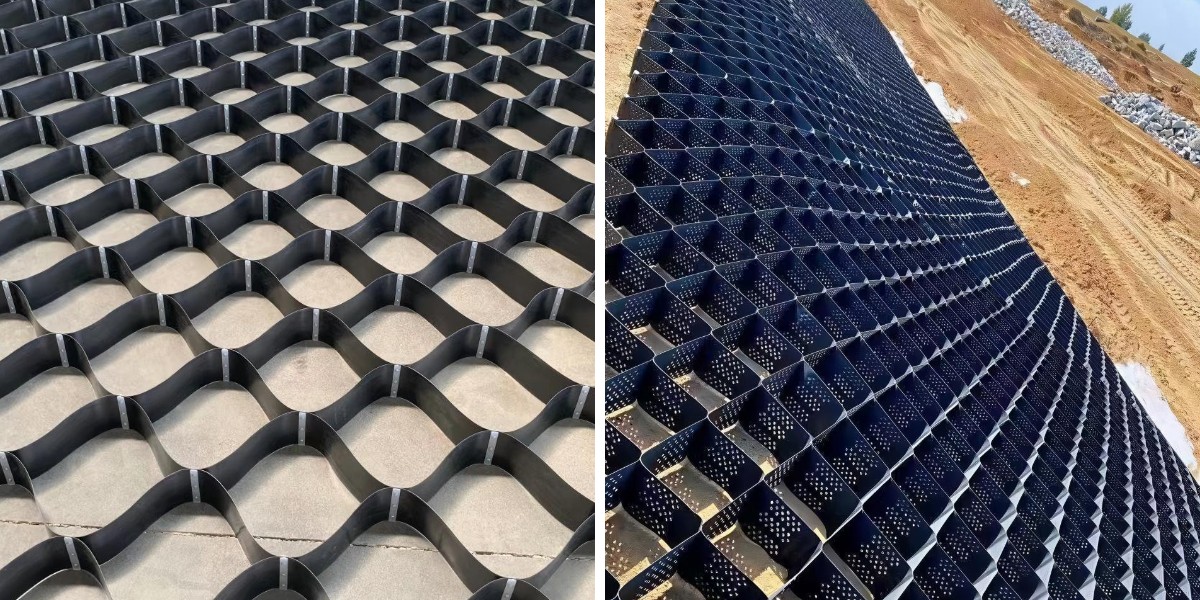

Outdoor building and environmental projects—from dual carriageway embankments to coastal erosion control—demand substances that can stand up to nature’s cruelest elements. For geocell slope safety and geocell erosion manipulate systems, two traits stand above the rest: UV resistance and chemical stability. These houses decide how nicely the geocell fabric keeps its strength, structure, and performance over time, even when uncovered to relentless sunlight, soil chemicals, and environmental stress. A geocell missing these features will degrade prematurely, main to slope failure, erosion, and pricey repairs. This information explores why UV resistance and chemical balance are non-negotiable for out of doors geocell use, how they’re engineered into geocell material, and their have an effect on on real-world functions of geocell slope safety and erosion control. By prioritizing these integral qualities, you can make certain your outside geocell task grants long-lasting, dependable results.

Why UV Resistance Matters for Outdoor Geocell Systems

Sunlight’s ultraviolet (UV) radiation is a silent destroyer of artificial materials. When geocell cloth is uncovered to UV rays, the radiation breaks down the polymer molecular bonds in the plastic—processes recognized as photo-oxidation. This degradation manifests as brittleness, discoloration, and loss of tensile strength. For geocell slope protection, this is catastrophic: a brittle geocell can crack or tear below soil pressure, failing to continue the fill cloth and leaving the slope inclined to erosion or collapse.

Outdoor geocells are uncovered to UV radiation daily, with depth various through local weather (e.g., hotter, sunnier areas like deserts or coastal areas pose increased risk). Even in temperate climates, cumulative UV publicity over months or years takes a toll. Unlike indoor materials, geocells can’t be shielded from daylight in most applications—making inherent or greater UV resistance a foundational requirement for geocell erosion manipulate and slope safety projects.

How Geocell Material Achieves UV Resistance

Manufacturers engineer geocell fabric for UV resistance thru two main methods: fabric resolution and additive integration. These tactics make certain the geocell retains its structural integrity for its supposed lifespan (typically 10–20 years for out of doors use).

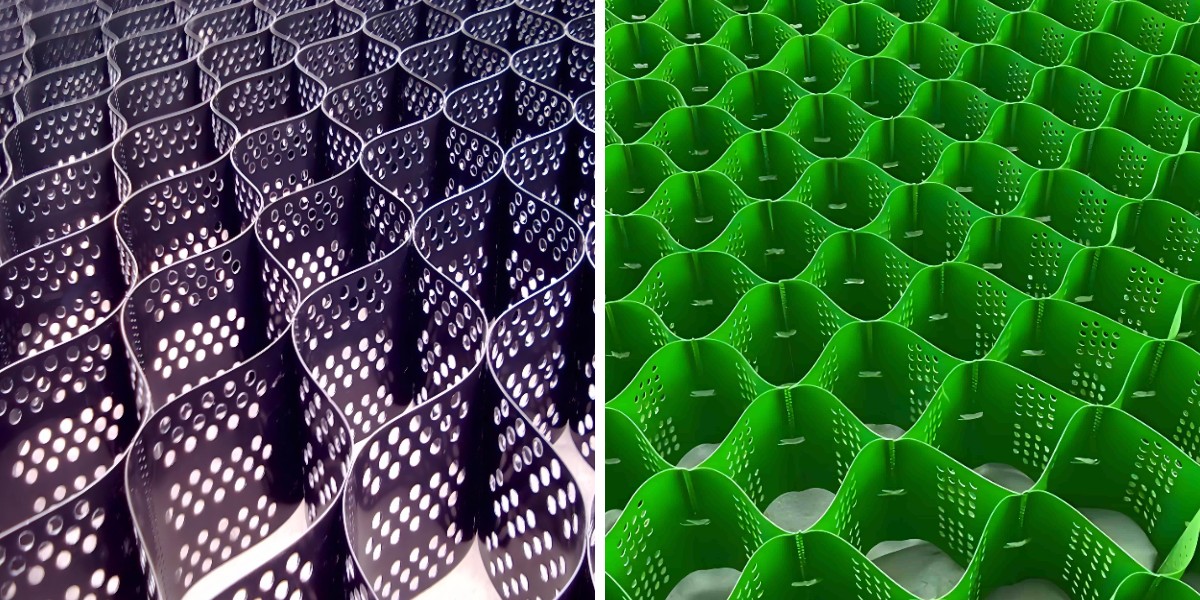

1. Polymer Selection

The base polymer of the geocell performs a crucial position in UV resistance. High-density polyethylene (HDPE) and polypropylene (PP) are the most frequent geocell cloth options, however they vary in herbal UV tolerance. HDPE has higher inherent UV resistance than PP, as its dense molecular shape slows photo-oxidation. For tasks in high-UV areas, HDPE is frequently the desired choice. Some producers additionally use modified polymers (e.g., UV-stabilized PP) to improve resistance, altering the polymer’s chemical shape to take in or mirror UV rays.

2. UV Stabilizers and Additives

Most out of doors geocells encompass UV stabilizers—chemical components that counteract UV damage. These stabilizers work in two ways: absorbers soak up UV radiation earlier than it reaches the polymer chains, and radical scavengers neutralize the chemical byproducts of photo-oxidation that spoil down the material. Common stabilizers encompass hindered amine mild stabilizers (HALS) and benzophenones, which are blended into the geocell fabric throughout manufacturing. The kind and awareness of stabilizers are tailor-made to the project’s climate, with greater doses used for excessive UV environments.

Chemical Stability: Defending Against Soil and Environmental Chemicals

Outdoor geocells are in steady contact with soil, water, and natural matter—all of which include chemical substances that can degrade the geocell material. Soil might also have various pH degrees (acidic or alkaline), excessive salt content material (in coastal areas), or comprise fertilizers, pesticides, or industrial contaminants. Water runoff can elevate pollutants, and natural count number decomposition produces acids. For geocell slope safety and geocell erosion manipulate to succeed, the geocell should withstand these chemical substances except swelling, cracking, or dropping strength.

Chemical degradation weakens the geocell’s structure, making it inclined to tearing or collapse. For example, an acidic soil can destroy down PP geocells over time, whilst saltwater can corrode positive polymer additives. Chemical steadiness ensures the geocell continues its overall performance regardless of the surrounding environment.

Key Chemical Resistance Traits of Geocell Material

High-quality geocell cloth is engineered to face up to a vary of chemical threats, with overall performance varying with the aid of polymer type:

1. pH Resistance

HDPE and PP geocells showcase high-quality resistance to each acidic and alkaline soils. HDPE, in particular, can stand up to pH tiers from two (strongly acidic) to thirteen (strongly alkaline)—covering the full-size majority of herbal soil conditions. This makes it appropriate for tasks in areas with acidic mine drainage or alkaline agricultural soils, the place geocell erosion manipulate is critical.

2. Salt and Moisture Resistance

Coastal and wetland tasks expose geocells to saltwater and regular moisture. Geocell cloth like HDPE is hydrophobic (water-repellent) and resistant to salt corrosion, stopping water absorption and swelling. This resistance ensures the geocell doesn’t end up heavy or brittle in wet, salty environments—essential for geocell slope safety alongside coastlines or tidal zones.

3. Resistance to Organic and Industrial Chemicals

In agricultural areas, geocells may additionally come into contact with fertilizers or pesticides. HDPE and PP withstand most natural chemicals, which includes nitrogen-based fertilizers and herbicides. For industrial websites (e.g., brownfield remediation), specialised geocells with stronger chemical resistance can stand up to solvents or heavy metallic contaminants, making sure geocell slope protection stays fine in difficult environments.

Real-World Impact: UV and Chemical Stability in Outdoor Applications

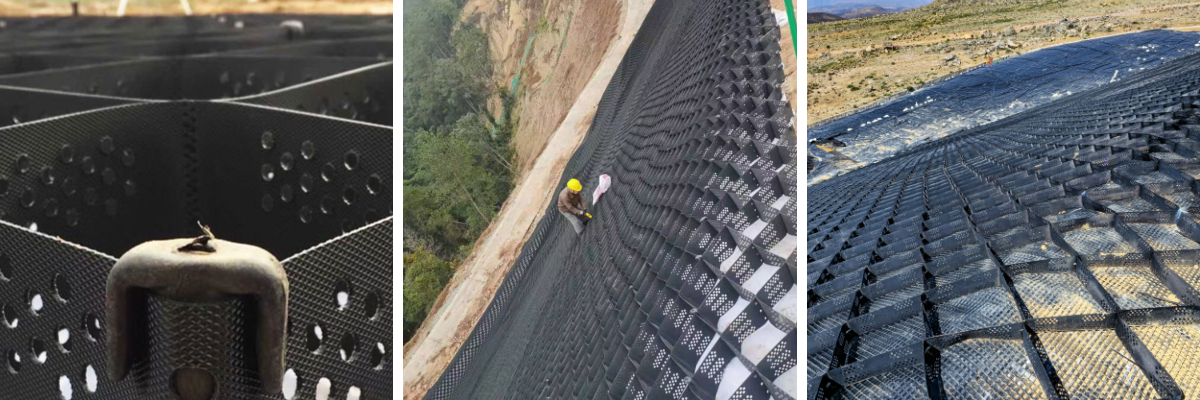

The significance of UV resistance and chemical balance will become clear in real-world geocell slope safety and geocell erosion manipulate projects:

1. Highway Embankments

Highway slopes are uncovered to excessive UV radiation and various soil chemicals. A UV-stabilized HDPE geocell retains its electricity for decades, stopping slope erosion and decreasing preservation costs. Without UV resistance, the geocell would degrade in 2–3 years, main to potholes, embankment collapse, and hazardous street conditions.

2. Coastal Erosion Control

Coastal geocells face UV radiation, saltwater, and alkaline soil. Chemical-stable geocell cloth resists salt corrosion and moisture absorption, preserving its shape to lure sand and stop seashore erosion. UV stabilizers make sure the geocell doesn’t emerge as brittle beneath the sun, even in tropical climates.

3. Agricultural Slopes

Agricultural slopes use geocells for erosion manipulate and soil retention. The geocell ought to face up to fertilizers, pesticides, and acidic/alkaline soil. Chemical-stable geocells keep away from degradation, ensuring they guide crop boom whilst preventing soil runoff. UV resistance protects them from consistent daylight in open fields.

Choosing the Right Geocell for Outdoor Use: What to Look For

When deciding on a geocell for out of doors geocell slope safety or geocell erosion control, prioritize these aspects associated to UV and chemical stability:

UV Stabilization Certification: Look for geocells examined and licensed for UV resistance (e.g., compliance with ASTM D4355 for UV exposure). Manufacturers have to supply records on anticipated lifespan in your climate.

Polymer Type: Choose HDPE for highest quality UV and chemical resistance, specially in harsh environments. For milder climates, UV-stabilized PP might also be cost-effective.

Chemical Resistance Testing: Ask for check reviews displaying resistance to pH extremes, saltwater, and frequent soil chemical compounds applicable to your project.

Warranty: A long-term assurance (5+ years) suggests the producer stands at the back of the geocell’s UV and chemical stability.

Conclusion: UV and Chemical Stability = Long-Term Outdoor Performance

For outside geocell slope safety and geocell erosion control, UV resistance and chemical balance are no longer optional—they’re essential. These traits make certain the geocell cloth withstands sunlight, soil chemicals, and environmental stress, turning in dependable overall performance for years. By selecting a geocell engineered with UV stabilizers, long lasting polymers, and chemical resistance, you can keep away from untimely failure, decrease protection costs, and defend your assignment from nature’s cruelest elements.

Don’t neglect these crucial features when deciding on a geocell. A cheap, non-stabilized geocell might also shop cash upfront however will fee a long way greater in repairs and replacements down the line. Invest in a geocell with tested UV and chemical stability, and your outside undertaking will stand strong—even in opposition to the sun, soil, and time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province