Using Geomembranes in Road Construction: Enhancing Durability

In the world of infrastructure development, avenue sturdiness is a pinnacle priority. Roads face regular stress from heavy traffic, altering climate conditions, and soil movement, which can lead to cracks, potholes, and expensive repairs. One progressive answer that has received large interest in latest years is the use of geomembranes. These versatile substances play a necessary position in reinforcing avenue structures, stopping water damage, and extending the lifespan of roads. In this article, we’ll discover how geomembranes, consisting of HDPE geomembrane and easy geomembrane, are remodeling street building and why they’re turning into a go-to desire for engineers and contractors.

The Role of Geomembranes in Road Construction: A Foundation for Longevity

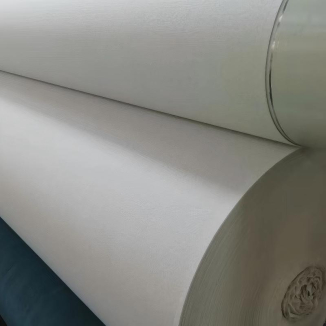

Geomembranes are thin, bendy sheets made from artificial substances designed to act as limitations or separators in civil engineering projects. In street construction, their predominant feature is to guard the street base from exterior elements that can compromise its integrity. Whether it’s stopping water infiltration, keeping apart specific soil layers, or reinforcing susceptible subgrades, geomembranes provide a cost-efficient way to beautify durability.

Water is one of the largest enemies of street structures. When water seeps into the street base, it weakens the soil, reasons erosion, and leads to uneven settlement. Over time, this can end result in cracks, rutting, and even entire street failure. Geomembranes act as a dependable water resistant barrier, stopping water from penetrating the base layers. This no longer solely preserves the power of the soil however additionally reduces the want for well-known maintenance.

Another key function of geomembranes is soil separation. Roads are constructed in layers, with each layer serving a precise purpose—from the subgrade (the herbal soil) to the base course, subbase, and subsequently the asphalt or concrete surface. Without applicable separation, pleasant particles from one layer can combine with coarser particles in another, decreasing the ordinary steadiness of the road. Geomembranes forestall this mixing, making sure every layer features as intended.

HDPE Geomembrane: A Durable Choice for Road Applications

High-Density Polyethylene (HDPE) geomembrane is one of the most famous selections in avenue construction, and for suitable reason. Its special residences make it best for withstanding the harsh prerequisites roads face daily.

HDPE geomembrane is acknowledged for its fantastic power and resistance to chemicals, UV radiation, and temperature fluctuations. These traits make certain that it stays positive even in excessive environments, from hot, sunny climates to cold, snowy regions. Unlike some different materials, HDPE geomembrane doesn’t degrade effortlessly over time, making it a long-lasting answer for avenue projects.

One of the key blessings of HDPE geomembrane in street development is its impermeability. It creates a sturdy barrier that prevents water from seeping into the subgrade, which is indispensable for preserving the road’s structural integrity. By preserving the subgrade dry, HDPE geomembrane reduces the danger of soil erosion and settlement, which are most important motives of street damage.

HDPE geomembrane is additionally exceedingly flexible, permitting it to conform to the form of the floor under the road. This flexibility ensures a tight fit, even on uneven surfaces, and helps soak up the stress from heavy traffic. Additionally, it’s effortless to install, which can keep time and labor prices on building sites.

Smooth Geomembrane: Enhancing Performance in Specific Road Scenarios

While textured geomembranes are frequently used in functions the place friction is important, easy geomembrane has its personal set of blessings in street construction. Its smooth floor permits for less complicated set up and ensures a uniform barrier, making it a exceptional desire for positive street projects.

Smooth geomembrane is mainly advantageous in areas the place water drainage wants to be managed except compromising the barrier’s integrity. Its clean floor permits water to drift greater freely over it, which can assist stop pooling and minimize the threat of water strain constructing up in the back of the membrane. This is specifically beneficial in street sections that are inclined to heavy rainfall or have excessive groundwater levels.

Another gain of easy geomembrane is its capacity to minimize friction between layers. In street construction, this can be wonderful when putting extra materials on pinnacle of the membrane. The easy floor lets in for less difficult motion and placement of base path materials, making sure a extra even distribution and lowering the threat of harm to the membrane at some point of installation.

Smooth geomembrane additionally provides incredible chemical resistance, making it appropriate for roads constructed in areas the place the soil or groundwater carries hazardous substances. It can face up to publicity to oils, fuels, and different chemical compounds that would possibly leak from vehicles, defending the underlying soil and keeping the road’s stability.

Installing Geomembranes in Road Construction: Best Practices for Success

Proper set up is key to making sure that geomembranes, whether or not HDPE geomembrane, clean geomembrane, or other types, operate efficiently in avenue construction. Even the highest-quality geomembrane won’t supply outcomes if it’s now not mounted correctly. Here are some first-rate practices to follow:

First, web site education is crucial. The subgrade have to be proper graded and compacted to make sure a smooth, even surface. Any rocks, debris, or sharp objects that should puncture the geomembrane must be removed. This step helps forestall injury to the membrane and ensures a tight fit.

Next, the geomembrane have to be laid out carefully, with overlaps between sheets precise sealed. The kind of seaming relies upon on the material—HDPE geomembrane, for example, is frequently welded the usage of heat, whilst different kinds might also use adhesives or mechanical fasteners. Proper seaming ensures that there are no gaps in the barrier, stopping water from leaking through.

For easy geomembrane, it’s necessary to keep away from stretching the fabric too tightly at some stage in installation, as this can lead to tears or damage. Instead, it must be laid with a mild slack to enable for motion due to temperature modifications or floor settlement.

After installation, the geomembrane need to be inspected completely to test for any injury or defects. Any problems need to be repaired without delay to keep the integrity of the barrier. Finally, the base direction and different layers have to be positioned cautiously over the geomembrane, the use of gear that won’t puncture or tear the material.

The Future of Geomembranes in Road Construction: Innovations and Trends

As avenue building technological know-how continues to evolve, so do the purposes of geomembranes. Engineers and producers are continuously working to enhance geomembrane materials, making them even greater durable, cost-effective, and environmentally friendly.

One rising vogue is the improvement of geomembranes with greater sustainability features. For example, some producers are growing HDPE geomembrane the use of recycled materials, lowering the environmental have an impact on of street projects. Additionally, lookup is being performed on biodegradable geomembranes for brief street applications, such as development get entry to roads, which can limit waste after the venture is complete.

Another region of innovation is the integration of geomembranes with different materials, such as geotextiles, to create composite structures that provide improved performance. These composites can grant each separation and reinforcement, making them perfect for difficult avenue development sites.

As the demand for longer-lasting, extra resilient roads continues to grow, geomembranes are probable to play an even extra essential function in avenue construction. Their potential to guard towards water damage, decorate soil stability, and decrease renovation prices makes them a treasured asset for any street project.

Conclusion

Geomembranes have tested to be a game-changer in avenue construction, supplying a dependable way to beautify sturdiness and prolong the lifespan of roads. Whether it’s HDPE geomembrane offering a strong, impermeable barrier, easy geomembrane facilitating simpler set up and drainage, or different kinds of geomembranes addressing unique mission needs, these substances are supporting engineers and contractors construct higher roads.

By grasp the special residences and functions of geomembranes, and following exceptional practices for installation, street development tasks can gain from decreased upkeep costs, accelerated performance, and extended longevity. As technological know-how advances, we can anticipate to see even greater progressive makes use of for geomembranes in avenue construction, making sure that our roads continue to be robust and dependable for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province