Mining Containment Solutions: Geomembranes for Heap Leach Pads, Tailings Dams, and Process Ponds

In the contemporary mining industry, tremendous containment is now not simply a regulatory requirement—it is a vital thing of environmental stewardship, operational safety, and long-term monetary viability. Containment buildings such as heap leach pads, tailings storage facilities, and method ponds are engineered to control giant volumes of probably hazardous materials. The integrity of these buildings hinges on one necessary element: the geomembrane liner system. This article explores how superior membrane liners, consisting of PVC geomembrane and bolstered polypropylene geomembrane, grant sturdy options for the mining sector's special containment challenges.

The Critical Role of Geomembranes in Mining Operations

Mining operations contain coping with large portions of ore, chemical solutions, and procedure water. Without dependable containment, hazardous contaminants can leach into the surrounding soil and groundwater, main to extreme environmental damage, regulatory penalties, and highly-priced remediation projects. Geomembranes serve as impermeable barriers, keeping apart mining by-products from the herbal environment.

These artificial membrane liners are engineered for durability, chemical resistance, and longevity. They shape the main or secondary layer in composite lining systems, making sure that even below annoying conditions, containment stays intact. The choice of the fabulous geomembrane—be it a bendy PVC geomembrane for complicated terrain or a strong bolstered polypropylene geomembrane for heavy loads—is a integral engineering selection that affects the complete project's success.

Securing Heap Leach Pads with Advanced Liner Systems

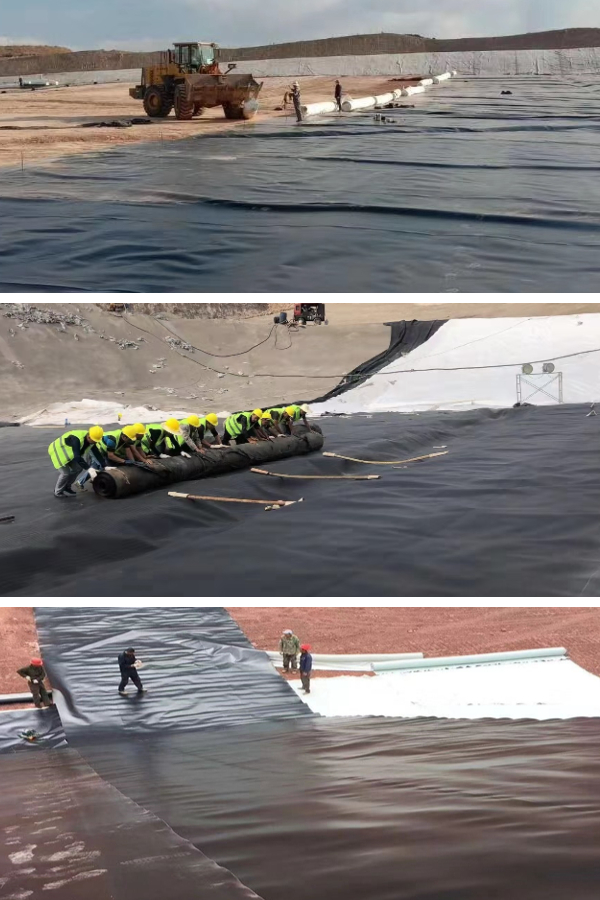

Heap leaching is a extensively used technique for extracting metals like gold, copper, and uranium from ore. The procedure includes stacking beaten ore into massive piles (heaps) and making use of a chemical answer that percolates thru the material, dissolving the goal metals. The containment of this pregnant answer is paramount.

The predominant undertaking for heap leach pads is the aggregate of aggressive chemical exposure, sharp ore materials, and tremendous mechanical stress from stacking. A failure in the liner gadget can lead to treasured answer loss and environmental contamination.

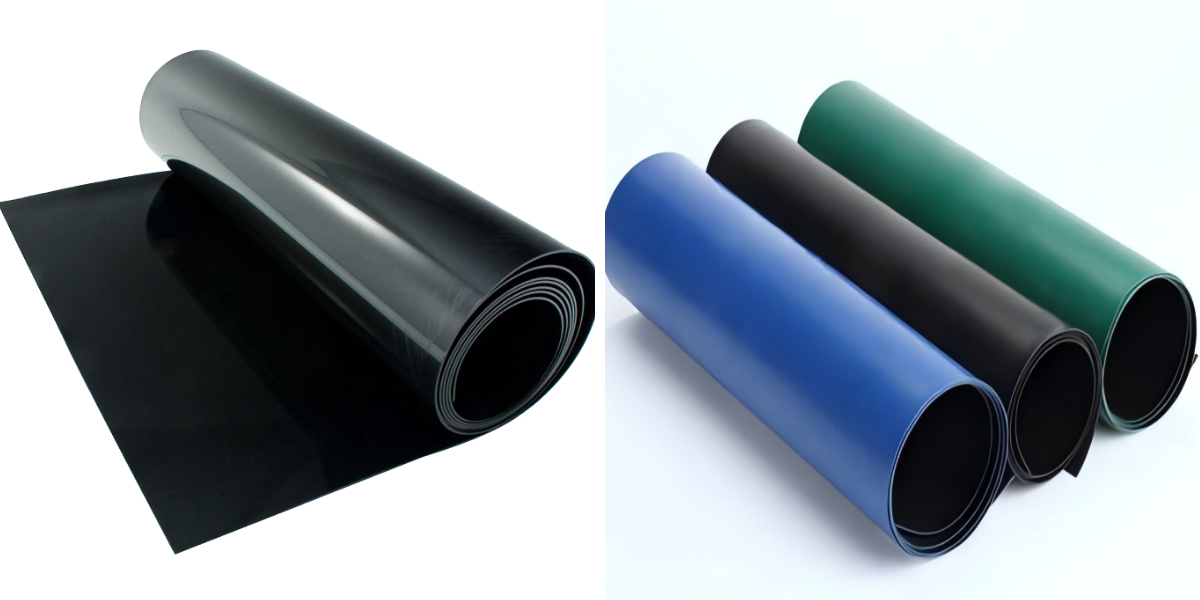

This is the place a high-performance PVC geomembrane frequently turns into the cloth of choice. Known for its great chemical compatibility, specifically with acidic and saline options frequent in leaching, PVC gives top-quality flexibility. This lets in it to conform carefully to the subgrade and face up to differential agreement barring cracking. As a fundamental thing of the membrane liners machine for leach pads, it is regularly mounted in conjunction with shielding geotextiles and drainage layers to create a complete containment solution.

Ensuring the Stability of Tailings Dams with Robust Liners

Tailings dams are amongst the biggest and most indispensable containment constructions in mining. They are designed to shop the fine-grained, regularly chemically reactive, waste substances (tailings) left over after ore processing. The catastrophic failure of a tailings dam is one of the mining industry's most enormous risks, making liner integrity non-negotiable.

Tailings dams demand liners with outstanding long-term strength, puncture resistance, and stability. The liner ought to aid the weight of the tailings slurry and withstand manageable degradation from a complicated combine of minerals and method chemical substances over decades.

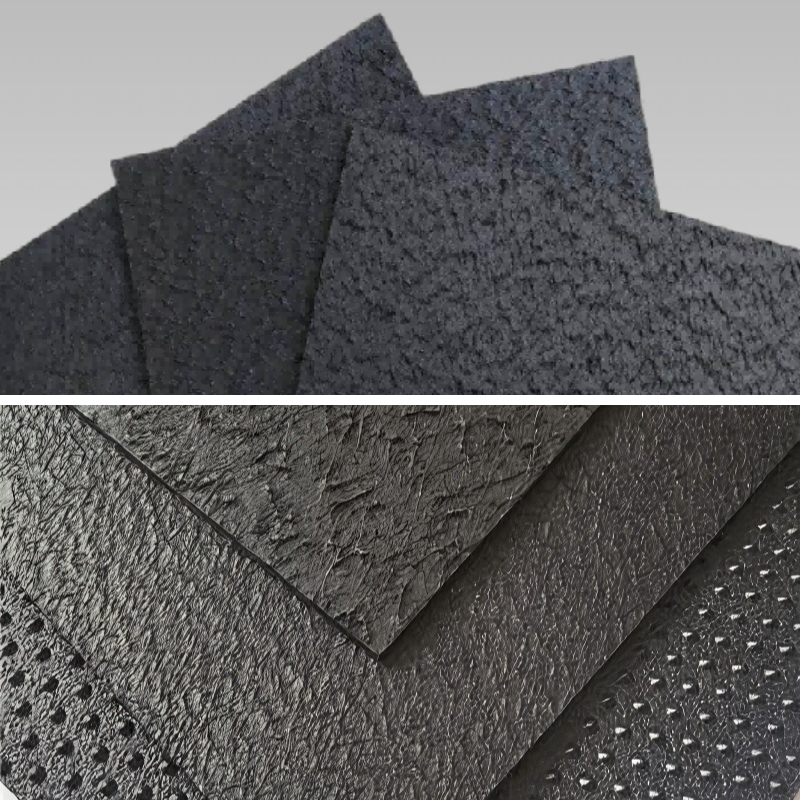

For these high-stress applications, a strengthened polypropylene geomembrane affords an remarkable solution. The reinforcement grid, usually made of high-tenacity polyester, offers the cloth great tensile electricity and dimensional stability. This makes it especially resistant to puncture and stress cracking below the consistent load of the tailings. When specifying membrane liners for tailings containment, the strengthened polypropylene geomembrane is regularly chosen for its confirmed overall performance in growing a secure, long-lasting basal liner or cowl machine that minimizes seepage and promotes dam stability.

Protecting Process Ponds with Chemical-Resistant Liners

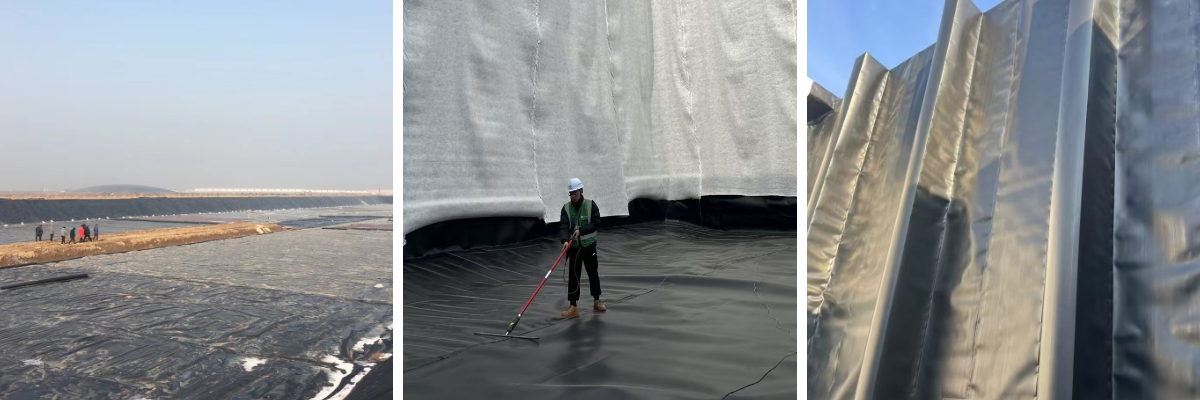

Process ponds are ubiquitous in mining operations, used for the whole thing from solvent extraction and solvent recuperation to water administration and sedimentation. These ponds maintain manner fluids, pregnant solutions, or handled water, every with precise chemical properties.

The key consideration for system ponds is chemical compatibility. The liner fabric need to withstand degradation from the unique fluids it will contain, which can vary from enormously acidic to caustic, and may additionally incorporate natural solvents or excessive concentrations of salts.

A extraordinary PVC geomembrane excels in this numerous chemical environment. Its system can be tailor-made for better resistance to a extensive spectrum of chemicals, presenting a dependable barrier that continues its impermeability over time. Furthermore, the seams of PVC geomembranes can be thermally welded to create strong, monolithic sheets, in reality putting off the danger of leakage at seams—a frequent failure factor in fluid containment. Whether used in a clarification pond or a pregnant answer pond, these membrane liners are necessary for stopping fluid loss and defending underlying aquifers.

Selecting the Right Geomembrane for Your Mining Project

Choosing the right geomembrane is a complicated choice that ought to be based totally on a particular site-specific analysis. Key elements include:

Chemical Exposure: A complete chemical compatibility evaluation is the first step. Both PVC geomembrane and bolstered polypropylene geomembrane provide sturdy chemical resistance, however their overall performance profiles vary for particular compounds.

Physical Stresses: Consider subgrade conditions, load bearing (static and dynamic), and plausible for puncture. The excessive tensile electricity of a bolstered polypropylene geomembrane is perfect for areas with excessive stress.

Installation Conditions: Climate, web site accessibility, and seam integrity necessities all have an impact on cloth choice. The flexibility and ease of seaming of PVC geomembrane can be effective in cooler climates or on uneven subgrades.

Long-Term Performance: The project's layout lifestyles dictates the required sturdiness and UV resistance of the membrane liners.

Consulting with skilled geosynthetic engineers and producers at some point of the sketch segment is essential to choosing a lining machine that ensures safety, compliance, and cost-effectiveness.

Conclusion: Building a Sustainable Future with Superior Containment

The accountability of present day mining extends some distance past useful resource extraction. It encompasses the safe, secure, and environmentally sound administration of all substances at some point of the project's lifecycle and beyond. The geomembrane liner is the silent guardian of this commitment, forming the necessary barrier between industrial manner and herbal ecosystem.

From the bendy containment of a PVC geomembrane on a heap leach pad to the ambitious power of a bolstered polypropylene geomembrane in a tailings dam, contemporary membrane liners provide engineered options for each challenge. By investing in the correct, remarkable geomembrane device for heap leach pads, tailings dams, and technique ponds, mining groups now not only guard the surroundings and surrounding communities however additionally protect their operational belongings and their social license to operate. In the pursuit of sustainable mining, superior geomembrane science is an crucial foundation.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province