Installation Best Practices for PVC Geomembrane

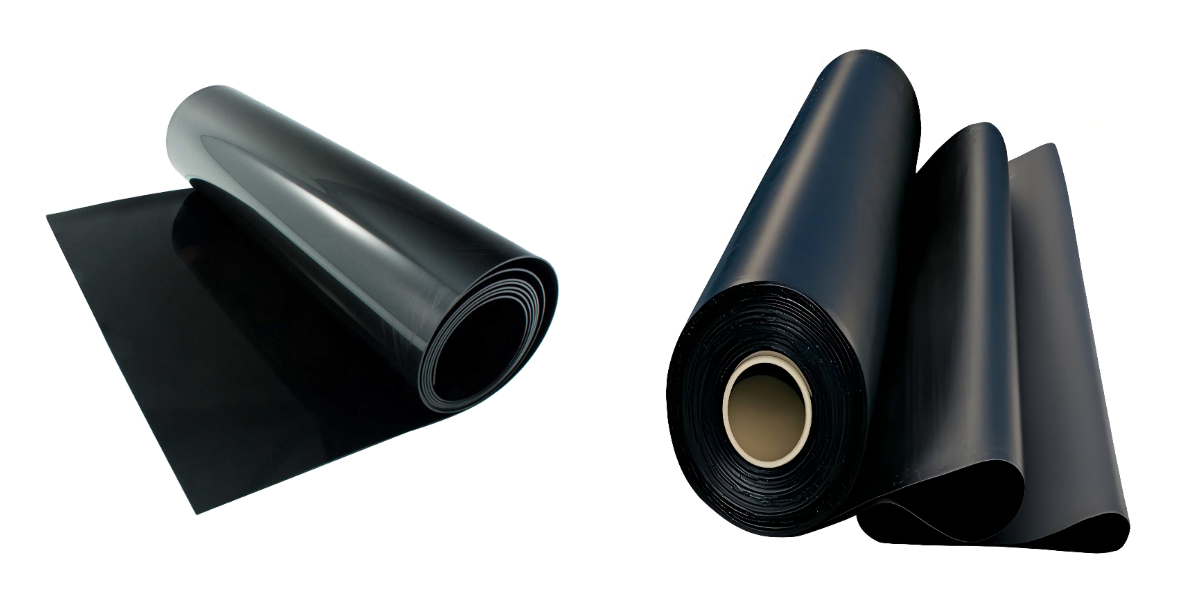

A PVC geomembrane is a premier preference for developing a flexible, durable, and impenetrable geomembrane liner in purposes ranging from potable water reservoirs to landfill caps. Its performance, however, is solely as dependable as its installation. A flawlessly manufactured sheet can be compromised through bad discipline practices, main to leaks, assignment delays, and steeply-priced repairs. Unlike extra inflexible substances like PE geomembrane (HDPE), PVC's flexibility is an asset that needs unique coping with and seaming techniques. This information outlines the imperative high-quality practices for putting in PVC geomembrane, making sure the cloth achieves its designed cause as a long-term, impermeable barrier. Following these protocols is the definitive thing between a profitable mission and a compromised one.

Phase 1: Pre-Installation Planning and Subgrade Preparation

The work completed earlier than the liner ever arrives on website is foundational to success.

1. Comprehensive Site and Material Review

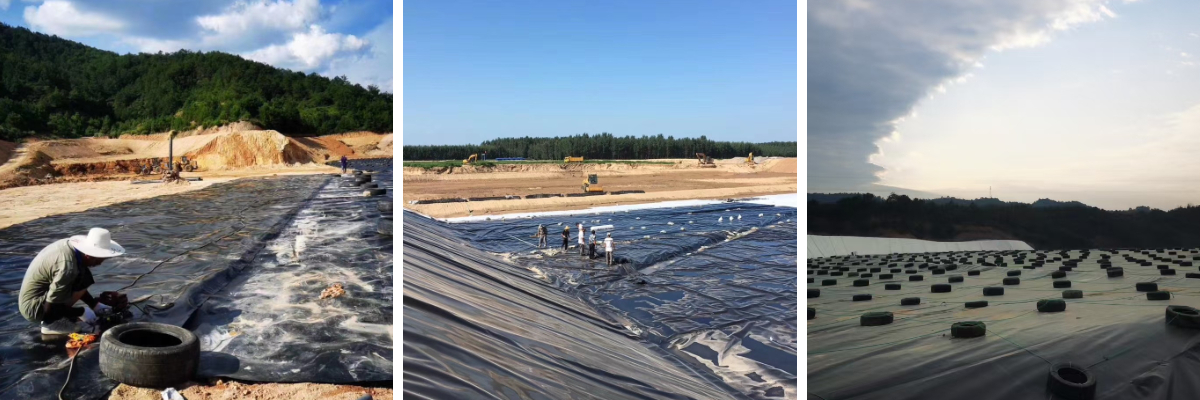

Begin with a distinctive evaluation of the engineered drawings and specifications. Verify that the delivered PVC geomembrane rolls fit the required thickness, formulation, and first-rate assurance certificates. Concurrently, look into the subgrade—the floor upon which the liner will be placed. It should be smooth, compacted, and free of sharp rocks, roots, or particles that ought to puncture the material. A well-prepared subgrade is non-negotiable for any invulnerable geomembrane system, as it prevents localized stress factors and underlying contract that can stress seams.

2. Weather and Storage Considerations

PVC have to be established in favorable climate conditions. Ideal temperatures are normally between 40°F (5°C) and 80°F (27°C). The cloth will become stiff and hard to manage when bloodless and can enlarge and come to be overly smooth in intense heat. Rolls need to be saved on flat, easy floor and stored blanketed with opaque, UV-protective tarpaulins till the second of deployment to forestall untimely degradation from sunlight. This cautious dealing with differentiates it from the storage of a polypropylene geomembrane or PE geomembrane, which may additionally have exclusive UV and thermal steadiness profiles.

Phase 2: Deployment, Panel Layout, and Initial Seaming

This section units the geometric and structural framework for the whole liner.

1. Strategic Panel Placement and Alignment

Unroll panels in accordance to the permitted format plan, permitting the fabric to loosen up and acclimate to ambient temperature. Panels need to be laid with adequate overlap (typically three to 6 inches) for the unique seaming method. It is indispensable to keep away from dragging the geomembrane throughout the subgrade. Instead, use controlled unrolling and positioning techniques. Proper alignment minimizes stress and the want for area trimming, making sure a neat and environment friendly installation. The intention is to create a contiguous discipline of material, a good deal like one would with a PE geomembrane, however with greater preliminary conformity to subgrade contours.

2. Tack Welding and Preliminary Seam Preparation

Before full seaming, panels are frequently briefly constant in vicinity the usage of a "tack weld" or tape alongside the overlap. This step prevents motion due to wind or employee traffic. The seam region have to then be meticulously cleaned with a lint-free material and accredited cleaner to put off all moisture, dust, and dirt. Any infection between the layers will create a vulnerable factor in the ultimate seam. This attention to cleanliness is universally critical, whether or not seaming PVC, a polypropylene geomembrane, or any different polymeric liner.

Phase 3: The Critical Seaming Process

Creating a continuous, monolithic barrier is the core goal of installation. For PVC, this is chiefly done thru solvent or thermal welding.

1. Solvent Welding (Chemical Fusion)

This is the most frequent approach for manufacturing unit and area seams in PVC. A precise solvent cement is utilized to the overlapped part of the pinnacle sheet. The solvent briefly dissolves the polymer surfaces. When pressed collectively beneath a seam roller, the PVC molecules from each sheets intermingle and, as the solvent evaporates, re-solidify into a single, homogeneous piece of material. The seam electricity can method that of the mum or dad sheet. The procedure requires a well-ventilated region and strict adherence to the manufacturer's endorsed open time and utility rate.

2. Hot-Air or Thermal Welding

For positive PVC formulations or in unique conditions, hot-air welding with an automatic wedge might also be used. This technique makes use of heated air to soften the surfaces, which are then without delay pressed collectively by means of a roller. It requires expert operators to keep the right temperature, speed, and pressure. While extra frequent for PE geomembrane projects, it is a achievable method for PVC when specified.

3. Seam Testing and Inspection

Every inch of each and every seam need to be viewed a doable failure point. Non-destructive checking out methods, such as an air lance or vacuum container testing, are used to pick out channels or holes in the seam. Destructive testing, the place pattern coupons are reduce from the ends of manufacturing seams and examined for shear and peel energy in a lab, is additionally a popular requirement to affirm seam integrity. This rigorous best manage is what makes the closing product a authentic invulnerable geomembrane.

Phase 4: Detail Work, Anchoring, and Protection

The liner's interplay with buildings and the perimeter is the place many leaks occur.

1. Termination and Anchoring

The geomembrane ought to be securely terminated in a perimeter anchor trench. The liner is positioned into the trench, backfilled, and compacted to forestall slippage due to thermal enlargement or hydraulic pressures. Proper anchoring locks the complete machine in place.

2. Pipe Penetrations and Structural Details

All penetrations via the liner (for pipes, drains, etc.) require especially engineered boot details. These are prefabricated PVC aspects that are chemically welded to the foremost liner sheet, developing a watertight seal round the structure. The flexibility of PVC makes it enormously adaptable for complicated detailing in contrast to a stiffer PE geomembrane.

3. Installation of Protection Layers

Once the liner is hooked up and all seams are examined and approved, a shielding layer is right now placed. This is usually a non-woven geotextile or a layer of sand. Its reason is to defend the PVC geomembrane from puncture by means of the overlying substances (e.g., drainage stone, waste). This protecting layer is a vital remaining step that preserves the integrity of the mounted tightly closed geomembrane.

Conclusion: A System Built to Last

The best chemical resistance, flexibility, and seamability of PVC geomembrane make it an super preference for a vast vary of containment applications. However, its inherent blessings can solely be utterly realized thru meticulous, professional installation. By adhering to these first-rate practices—from subgrade instruction thru rigorous seaming and remaining protection—installers radically change rolls of artificial cloth into a reliable, long-lasting, and sincerely impenetrable geomembrane system. For mission proprietors and engineers, specifying these requirements and making sure certified set up is the closing guard for your project's overall performance and longevity, distinguishing a well-executed PVC set up from that of a polypropylene geomembrane or different alternative.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province