How to Maintain HDPE Geomembrane: Inspection, Repair & Longevity Tips

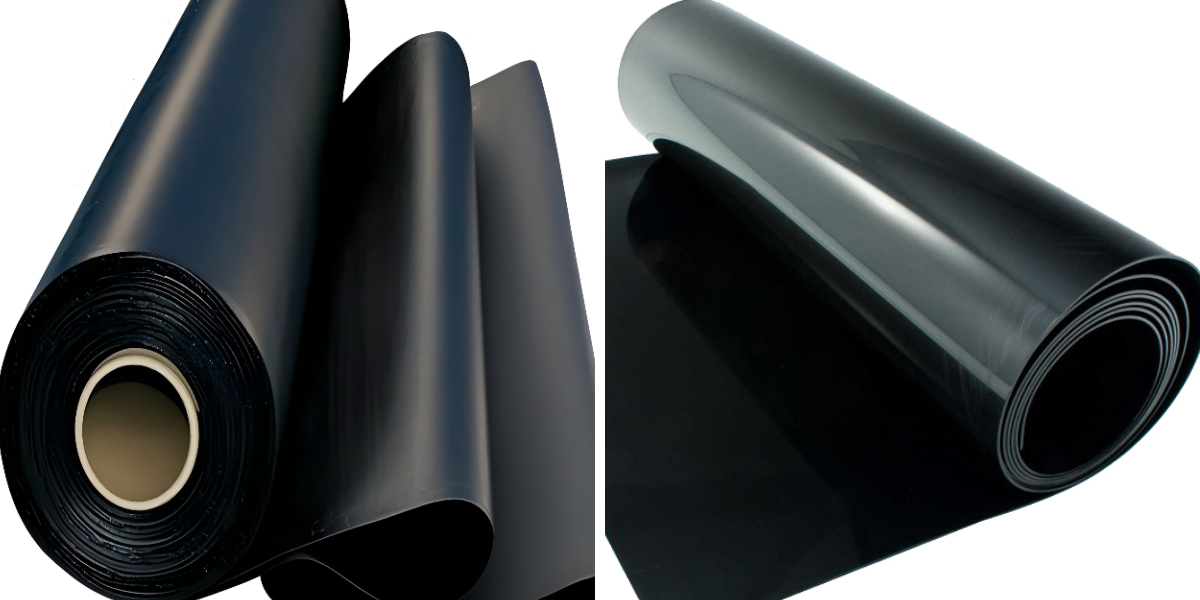

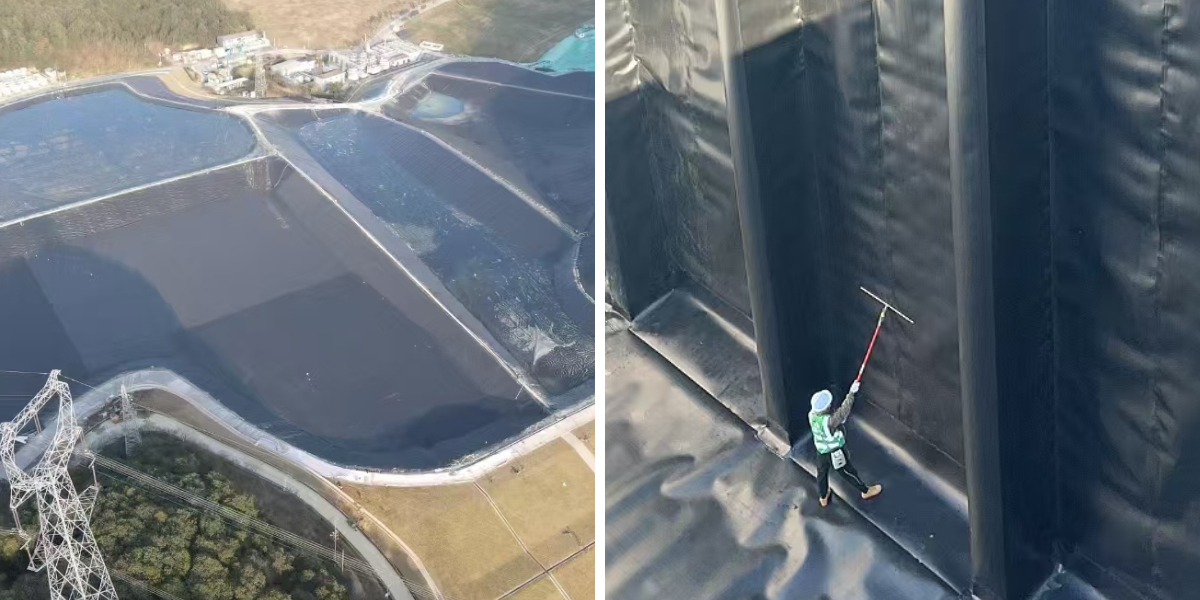

HDPE geomembrane is a versatile and long lasting fabric extensively used in landfill liners, water reservoirs, pond liners, and different geotechnical engineering projects. Its superb waterproof, anti-corrosion, and anti-ultraviolet homes make it a favored preference for long-term environmental safety and engineering stability. However, to make certain the most effective overall performance of HDPE geomembrane at some point of its provider life, scientific renovation strategies—including everyday inspection, well timed repair, and proactive durability measures—are essential. This article will element realistic renovation strategies from 4 core aspects, assisting you maximize the cost of your geomembrane funding and keep away from pricey engineering failures.

1. Regular Inspection of HDPE Geomembrane: The Foundation of Maintenance

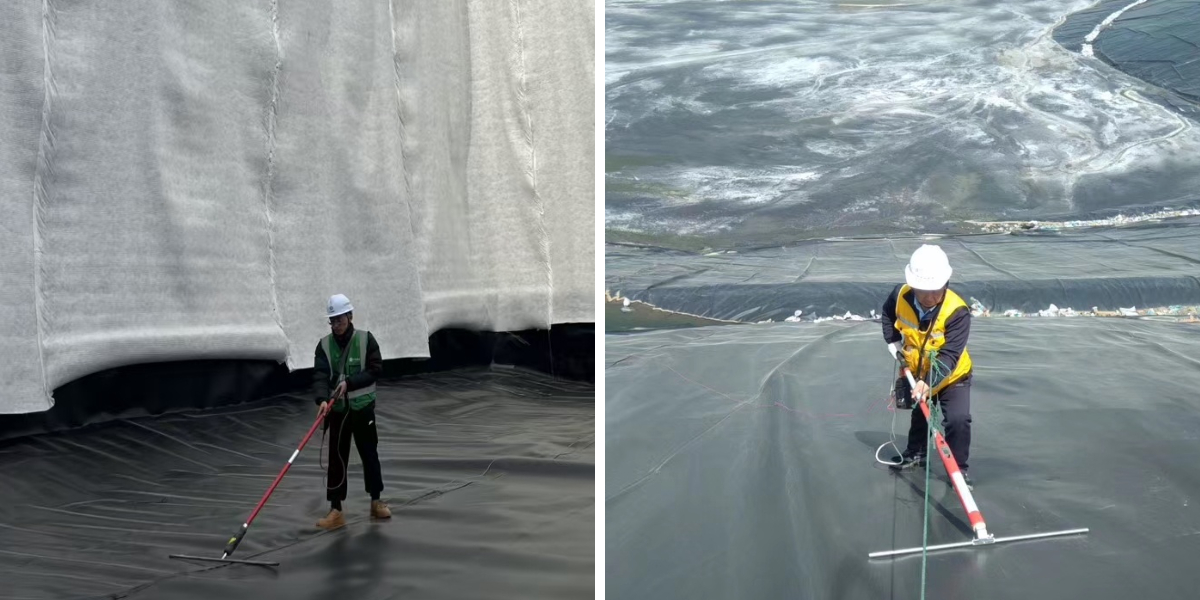

Regular inspection is the first line of protection to stop HDPE geomembrane damage. Timely detection of possible problems such as cracks, punctures, or seam screw ups can keep away from minor issues evolving into main leaks. Inspection work have to be systematic and cowl each movements tests and distinct assessments after severe conditions. Below are key inspection factors and methods:

1.1 Daily Visual Inspection

Conduct visible inspections at least as soon as a week, focusing on the floor of the HDPE geomembrane and its seams. Look for apparent damages such as tears, punctures, or bulges brought on via exterior objects (e.g., rocks, development debris, or animal activities). Pay one of a kind interest to areas round anchors, pipes, and edges—these are high-stress zones susceptible to wear. During the inspection, mark any suspicious areas with non-toxic, weather-resistant markers for follow-up precise checks. This easy day by day events can efficiently perceive on the spot threats to the geomembrane.

1.2 Periodic Detailed Inspection (Quarterly/Annual)

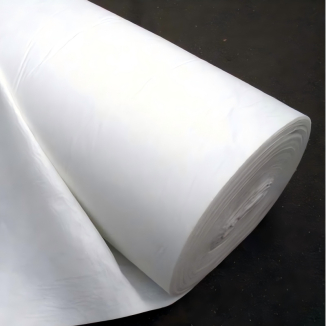

In addition to each day checks, operate complete unique inspections each and every quarter, with a extra thorough annual assessment. For large-scale projects, use expert equipment such as infrared thermal imaging cameras to realize hidden seam defects or moisture accumulation beneath the geomembrane that are invisible to the bare eye. Test the seam energy of the HDPE geomembrane the use of peel and shear assessments in accordance with enterprise standards—this is integral due to the fact seam failure is one of the most frequent reasons of leaks. Also, take a look at the integrity of add-ons such as geotextiles (used as defensive layers) and part fixings, as their harm can not directly have an effect on the geomembrane.

1.3 Emergency Inspection After Extreme Conditions

After extreme climate occasions (e.g., heavy rains, storms, or severe temperatures) or unintended affects (e.g., building equipment collisions), habits emergency inspections immediately. Extreme rainfall may additionally purpose water stress buildup, main to geomembrane stretching or tearing; robust winds can convey particles that punctures the material; and intense bloodless or warmness may also motive thermal growth and contraction, detrimental seams. Prompt emergency inspections can shortly pick out and tackle post-disaster damage, stopping secondary failures.

2. Timely Repair of HDPE Geomembrane: Stop Leaks Before They Worsen

Once injury is detected all through inspections, immediate and applicable restore is critical. Delayed repairs can lead to increasing damage, expanded restore costs, and even environmental risks (e.g., leakage of poisonous waste in landfills). The restore technique relies upon on the kind and dimension of the damage, and all repairs need to comply with geomembrane set up recommendations to make sure compatibility and durability.

2.1 Preparation for Repair

Before repairing, easy the broken place and its surrounding 30-50 cm thoroughly. Remove dirt, oil, moisture, and any free particles the usage of a brush, cloth, or high-pressure air blower. Ensure the floor is dry and smooth—moisture or contaminants can have an effect on the adhesion of restore materials. For bloodless or humid environments, use heating tools to dry the area, however keep away from overheating the HDPE geomembrane, as this can purpose thermal damage.

2.2 Repair Methods for Common Damages

For small punctures or cracks (less than five cm): Use HDPE patch repair. Cut a patch that is at least 10 cm large than the harm on all sides, making sure the patch cloth suits the authentic geomembrane (same thickness and resin type). Apply a like minded HDPE adhesive to each the patch and the broken area, then press firmly to put off air bubbles. Allow the adhesive to remedy utterly in accordance to the manufacturer’s directions (usually 24-48 hours) earlier than resuming use.

For giant tears or seam screw ups (more than five cm): For giant tears, use a mixture of patches and warmness welding. First, trim the edges of the tear to make them neat and smooth, then location a massive HDPE patch over the region and weld it to the authentic geomembrane the usage of a warm air gun or computerized welding machine. For seam failures, re-weld the affected seam after cleansing and drying, and behavior a vacuum check to confirm the weld integrity. For vital areas (e.g., landfill backside liners), think about changing the broken area completely to make certain long-term reliability.

2.3 Post-Repair Verification

After finishing the repair, behavior strict verification tests. For adhesive repairs, function a peel check to make sure the patch adheres firmly (the patch must now not peel off when pulled). For heat-welded repairs, use a vacuum field take a look at or air stress check to test for leaks—if bubbles shape throughout the test, it shows a inaccurate weld that desires reworking. Only after passing the verification can the repaired location be put lower back into service.

3. Proactive Measures to Extend HDPE Geomembrane Longevity

In addition to inspection and repair, proactive renovation measures can considerably lengthen the carrier existence of HDPE geomembrane. These measures focal point on lowering exterior damage, mitigating environmental impacts, and optimizing operational conditions, making sure the fabric keeps its overall performance for decades.

3.1 Prevent Physical Damage

Physical harm is the main motive of HDPE geomembrane failure. To forestall this, deploy a shielding geotextile layer over the geomembrane in high-traffic areas (e.g., development zones, get right of entry to roads) or areas with sharp objects (e.g., gravel, tree roots). Restrict the use of heavy equipment on the geomembrane surface—if equipment need to be used, vicinity rubber mats or timber planks below the gear to distribute weight. Additionally, limit unauthorized get admission to to the geomembrane region to keep away from unintentional injury from people or animals.

3.2 Mitigate Environmental Hazards

HDPE geomembrane is resistant to most chemicals, however extended publicity to robust oxidants, solvents, or high-concentration acids/bases can degrade the material. For tasks involving chemical storage (e.g., industrial ponds), typically screen the chemical composition of the saved substance to make certain it is well suited with HDPE. In out of doors applications, ultraviolet (UV) radiation can motive long-term ageing of the geomembrane—choose HDPE geomembrane with UV stabilizers, and reflect onconsideration on including a protecting cowl (e.g., soil, vegetation) in areas with severe sunlight. For bloodless regions, keep away from permitting water to accumulate on the geomembrane in winter, as freezing and thawing can motive cracking.

3.3 Optimize Operational Management

Proper operational administration is key to extending geomembrane longevity. Avoid overfilling reservoirs or landfills, as immoderate water stress or waste weight can stretch and harm the geomembrane. For landfill liners, manage the fee of waste deposition to distribute the load evenly. Regularly easy drainage structures to stop water buildup, which can exert immoderate strain on the geomembrane. Additionally, set up a complete protection document device to tune inspection results, restore work, and operational changes—this helps pick out long-term developments and optimize renovation strategies.

4. Post-Installation Maintenance: Lay the Groundwork for Long-Term Performance

Geomembrane set up satisfactory immediately impacts protection necessities and carrier life. Post-installation upkeep focuses on verifying set up quality, addressing preliminary issues, and setting up a renovation movements to make sure the geomembrane begins performing optimally from day one.

4.1 Post-Installation Inspection and Acceptance

Immediately after geomembrane installation, habits a full-scale inspection and acceptance test. Check the integrity of seams, side fixings, and connections to pipes or structures. Use non-destructive trying out strategies (e.g., vacuum tests, spark tests) to discover hidden leaks. Any set up defects (e.g., incomplete welds, free anchors) have to be corrected earlier than the challenge is commissioned. This post-installation inspection ensures that the geomembrane is mounted efficiently and gives a baseline for future maintenance.

4.2 Initial Monitoring Period

During the first 3-6 months after set up (the preliminary monitoring period), extend the frequency of inspections. This is due to the fact the geomembrane may also bear preliminary contract or thermal adaptation, main to stress concentrations or seam issues. Monitor the geomembrane for symptoms of stretching, wrinkling, or displacement, and tackle any problems promptly. For water storage projects, fill the reservoir regularly to permit the geomembrane to alter to water pressure, decreasing the threat of surprising damage.

4.3 Training and Documentation

Train on-site personnel on geomembrane upkeep basics, consisting of how to behavior visible inspections, perceive frequent damages, and record issues. Provide a certain protection guide that consists of inspection schedules, restore procedures, and emergency response plans. Ensure all upkeep work is documented, consisting of dates, locations, methods, and substances used. This documentation is no longer solely beneficial for everyday protection however additionally for compliance with regulatory necessities and guarantee claims.

Conclusion

Maintaining HDPE geomembrane requires a mixture of ordinary inspection, well timed repair, proactive sturdiness measures, and post-installation care. By enforcing the techniques outlined in this article, you can correctly stop damage, prolong the carrier lifestyles of the geomembrane, and make certain the long-term balance and protection of your engineering project. Remember, the key to profitable geomembrane renovation is consistency—investing time and sources in ordinary preservation is a long way greater not pricey than addressing foremost screw ups later. Whether you are managing a landfill, water reservoir, or any different assignment the use of HDPE geomembrane, following these recommendations will assist you get the most out of your investment.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province