How to Choose the Right Size of Dewatering Bags for Sludge Treatment

Introduction: The Impact of Size on Dewatering Efficiency

Dewatering luggage are a cornerstone of sludge treatment, providing a in your price range way to separate water from solids in construction, municipal, and industrial projects. However, selecting the incorrect measurement can lead to inefficiencies: undersized baggage require usual replacement, whilst outsized ones waste house and gradual down water drainage. In this guide, we’ll smash down the steps to pick the ideal dewatering bag size, thinking about sludge volume, website online constraints, and fabric compatibility—with insights into how geotextile tube technological know-how informs these decisions.

Key Factors to Consider Before Choosing Size

1. Sludge Volume and Solid Content

Start via calculating the complete quantity of sludge to be treated. A 10-cubic-meter batch of sludge with 5% strong content material (95% water) will decrease considerably after dewatering, however you nonetheless want a bag massive adequate to preserve the preliminary volume. As a rule, pick a bag that can preserve 1.5 instances the uncooked sludge extent to account for growth at some point of filling.

For reference:

Small tasks (1–5 cubic meters): 1–3 cubic meter bags.

Medium tasks (5–50 cubic meters): 5–20 cubic meter bags.

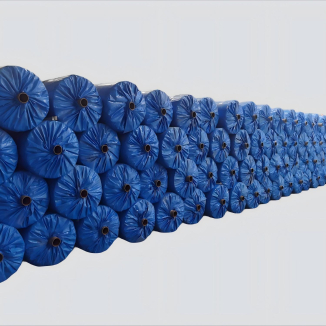

Large initiatives (50+ cubic meters): Consider geotextile tube systems, which are surely outsized dewatering baggage designed for high-volume sludge.

2. Site Space and Accessibility

Measure the reachable house for dewatering. Narrow building websites may also require long, slender luggage (e.g., 2m large x 5m long) as an alternative of rectangular ones, whilst open areas can accommodate larger, extra environment friendly shapes. Also, make sure there’s room for tools to fill the bags—oversized baggage in tight areas may additionally be not possible to load properly.

3. Drainage Requirements

Smaller luggage (1–5 cubic meters) drain water quicker due to their greater floor area-to-volume ratio, making them perfect for sludge with excessive water content. Larger luggage or geotextile tube systems, however, are higher for thick sludge (10%+ strong content) the place slower, greater managed drainage prevents solids from escaping with the water.

How Geotextile Tube Specifications Inform Size Choices

Geotextile tube systems, used for large-scale sludge treatment, provide treasured classes for dewatering bag selection. Their graph is guided by using Specifications of geotextile tubes, which encompass diameter, length, and material porosity—factors that at once observe to smaller dewatering bags.

Diameter vs. Length: In geotextile tube design, a 3m diameter x 10m size tube balances extent and drainage. For dewatering bags, a comparable ratio (width 1–2m, size 2–4m) works well, making sure water can break out evenly barring pooling.

Fabric Strength: Geotube Material Specifications (e.g., tensile electricity 10–20 kN/m) make sure the tube withstands sludge weight. For dewatering bags, pick material with energy matching size—larger luggage want thicker, superior geotextile to keep away from tearing.

Step-by-Step Guide to Sizing Dewatering Bags

1. Calculate Sludge Volume and Shrinkage

Use a sludge calculator to estimate post-dewatering volume. For example:

20 cubic meters of sludge (8% solids) → ~1.6 cubic meters of dry solids.

Choose a bag that holds the uncooked quantity (20 cubic meters) with more house for filling—opt for a 30 cubic meter bag.

2. Match Size to Site Constraints

If your website has a 10m x 5m dewatering zone, keep away from luggage longer than 8m (to go away house for loading and drainage).

For extended systems or trucks, restrict bag peak to 1.5m to forestall tipping in the course of filling.

3. Consider Material Compatibility

Dewatering baggage and geotextile tube structures matter on material porosity to drain water whilst maintaining solids. Check Geotube Material Specifications for guidance:

Fine sludge (clay-based) desires a tight weave (porosity 5–10 microns) in smaller baggage to entice solids.

Coarse sludge (sandy) works with large luggage and greater porous cloth (porosity 20–50 microns), permitting quicker drainage.

4. Test with Smaller Bags First

For unknown sludge types, begin with a small bag (1–3 cubic meters) to take a look at drainage rates. If water drains in 3–5 days barring dropping solids, scale up to large sizes the use of the equal dimensions.

Common Sizing Mistakes to Avoid

Oversizing for “Safety”: A 50 cubic meter bag for 20 cubic meters of sludge wastes fabric and slows drainage—water has to journey farther to escape.

Ignoring Weight Limits: A entirely stuffed 20 cubic meter bag can weigh 20+ tons. Ensure the site’s floor or platform can assist this; use a couple of smaller baggage if needed.

Mismatching to Geotextile Strength: Larger baggage want superior fabric. Refer to Specifications of geotextile tubes (which require 15+ kN/m tensile energy for giant sizes) to keep away from tears.

Sizing Examples for Different Projects

1. Municipal Wastewater Sludge (5% Solids)

Volume: 30 cubic meters.

Recommended size: forty cubic meter bag (2m vast x 5m lengthy x 4m high) with medium-porosity fabric.

Why: Balances extent with drainage speed, becoming in normal wastewater plant yards.

2. Construction Site Sludge (15% Solids)

Volume: 10 cubic meters.

Recommended size: 15 cubic meter bag (1.5m large x 4m lengthy x 2.5m high) with long lasting fabric.

Why: Small adequate for tight development sites, with power to take care of thicker sludge.

3. Industrial Sludge (20%+ Solids)

Volume: one hundred cubic meters.

Recommended: Geotextile tube machine (3m diameter x 20m length) with high-tensile cloth (per Geotube Material Specifications).

Why: Efficient for massive volumes, with managed drainage to manage thick sludge.

Conclusion: Size for Success in Sludge Treatment

Choosing the proper dewatering bag measurement requires balancing sludge volume, web site space, and cloth specs—lessons borrowed from geotextile tube design. By calculating volume, trying out with small bags, and warding off frequent mistakes, you’ll pick out a dimension that speeds up dewatering, reduces costs, and ensures solids are retained effectively. Whether you’re treating municipal or industrial sludge, the proper dimension turns dewatering from a chore into a streamlined process.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province