HDPE Geomembrane Storage Best Practices: Protecting Liners Before Installation

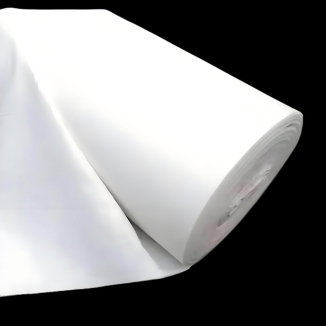

High-Density Polyethylene (HDPE) Geomembrane is a cornerstone in modern seepage control projects, from landfill liners to water storage ponds. Its durability, chemical resistance, and flexibility make it a top choice for engineers and contractors. However, even the highest-quality HDPE Geomembrane can fail prematurely if not stored properly before installation. Poor storage exposes the liner to physical damage, UV degradation, and environmental stressors that compromise its structural integrity. In this guide, we’ll break down the critical best practices for storing HDPE Geomembrane, ensuring your liners remain in optimal condition for a successful installation and long service life.

1. Control Storage Environment: Shield HDPE Geomembrane from Extreme Conditions

The storage environment is the first line of defense for preserving HDPE Geomembrane. This material is sensitive to extreme temperatures, direct sunlight, and moisture—all of which can degrade its properties before it even touches the installation site.

1.1 Temperature Regulation: Avoid Hot and Cold Extremes

HDPE Geomembrane softens in high temperatures and becomes brittle in freezing conditions. For optimal storage, maintain a consistent temperature between 5°C (41°F) and 30°C (86°F). If storing outdoors (a last resort), never leave the Geomembrane exposed to direct sunlight for more than 72 hours. Prolonged UV exposure breaks down the polymer chains, reducing tensile strength and elasticity. In hot climates, use white or reflective tarps to reflect sunlight and prevent heat buildup. In cold climates, store liners in insulated warehouses to avoid freezing—brittle Geomembrane is prone to cracking during handling.

1.2 Moisture and Humidity Management

Moisture is another silent threat. While HDPE Geomembrane itself is waterproof, trapped moisture between rolls can lead to mold growth or rust on metal packaging components, which can transfer to the liner and cause contamination. Store rolls on elevated pallets (at least 15 cm off the ground) to prevent contact with floor moisture. Ensure the storage area is well-ventilated to reduce humidity levels below 60%. If outdoor storage is unavoidable, use waterproof tarps that are tightly secured but allow for slight airflow to prevent condensation buildup.

2. Proper Stacking and Handling: Prevent Physical Damage to Geomembrane

Physical damage during storage—such as tears, punctures, or creases—can render HDPE Geomembrane unusable. Proper stacking and handling techniques minimize these risks and keep liners ready for installation.

2.1 Stack Height and Weight Distribution

Never stack HDPE Geomembrane rolls too high. The weight of top rolls can compress the bottom ones, causing permanent creases or deforming the liner’s shape. As a general rule, stack no more than 3-4 rolls high for standard 10m x 100m rolls. Use uniform pallets to ensure even weight distribution—avoid mixing roll sizes or weights in the same stack. Place heavier rolls at the bottom and lighter ones on top to maintain stability. Additionally, leave at least 60 cm of space between stacks and walls to allow for airflow and easy inspection.

2.2 Handling with Care: Avoid Sharp Objects and Rough Treatment

When moving HDPE Geomembrane rolls, use equipment with soft, non-abrasive grips—avoid metal hooks or forks that can puncture the liner. Always lift rolls from the center to prevent bending or twisting. Never drag rolls across the ground, as gravel, rocks, or debris can tear the surface. If using a forklift, ensure the tines are long enough to support the entire length of the roll to avoid splitting. For smaller rolls, use hand trucks with padded surfaces to minimize friction.

3. Regular Inspection and Maintenance: Catch Issues Early

Even with perfect storage conditions, HDPE Geomembrane requires regular inspections to identify potential problems before they escalate. A proactive inspection schedule ensures your liners are in top shape when installation day arrives.

3.1 Establish a Inspection Routine

Inspect HDPE Geomembrane rolls at least once per week if stored indoors, and twice per week if stored outdoors. Create a checklist to document key areas: surface condition (tears, punctures, or discoloration), roll shape (deformation or creases), packaging integrity (damaged wraps or covers), and storage environment (temperature, humidity, or water buildup). Assign a dedicated team member to conduct inspections and log findings—this ensures accountability and consistency.

3.2 Address Issues Immediately

If an inspection reveals damage, act quickly to prevent further deterioration. For small tears (less than 5 cm), use HDPE-compatible patch kits to seal the area—ensure the patch is larger than the tear and properly bonded. For larger damage, isolate the affected roll and label it as “unfit for installation” to avoid accidental use. If UV discoloration is detected (a yellowish hue), test the liner’s tensile strength with a portable tester—if it’s below the manufacturer’s specifications, replace the roll. For moisture buildup, reposition the tarp to improve airflow and wipe down rolls with a dry cloth.

4. Secure Storage and Inventory Management: Protect Against Theft and Misplacement

HDPE Geomembrane is a high-value material, making it a target for theft. Additionally, poor inventory management can lead to lost or misplaced rolls, delaying projects and increasing costs. Securing your storage area and managing inventory effectively is a critical part of best practices.

4.1 Secure the Storage Area

Store HDPE Geomembrane in a locked warehouse or fenced outdoor area with controlled access. Install security cameras to monitor the storage site 24/7, especially if storing large quantities. Use motion sensors or alarm systems to deter theft—this is particularly important for remote job sites. If using a third-party storage facility, verify their security measures and ensure they have insurance coverage for your Geomembrane.

4.2 Organize Inventory and Label Clearly

Organize rolls by size, thickness, and installation date to streamline access. Label each roll with clear, weather-resistant tags that include: manufacturer name, product specifications (thickness, width, length), production date, and storage arrival date. Use a digital inventory system to track rolls—scan barcodes or QR codes when rolls are received, moved, or inspected. This not only prevents misplacement but also helps you rotate inventory, ensuring older rolls are used first (first-in, first-out) to minimize storage time.

Final Thoughts: Invest in Storage to Maximize HDPE Geomembrane Performance

Proper storage of HDPE Geomembrane is not an afterthought—it’s an investment in the success of your project. By controlling the storage environment, stacking and handling rolls carefully, conducting regular inspections, and securing your inventory, you protect the liner’s integrity and ensure it performs as intended for decades. Remember, a damaged Geomembrane can lead to costly leaks, project delays, and rework—avoid these issues by following these best practices. Whether you’re storing liners for a landfill, pond, or industrial site, prioritizing storage will save you time, money, and headaches in the long run.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province