Geotextile Tubes in Riverbank Stabilization: Installation Tips and Long-Term Performance

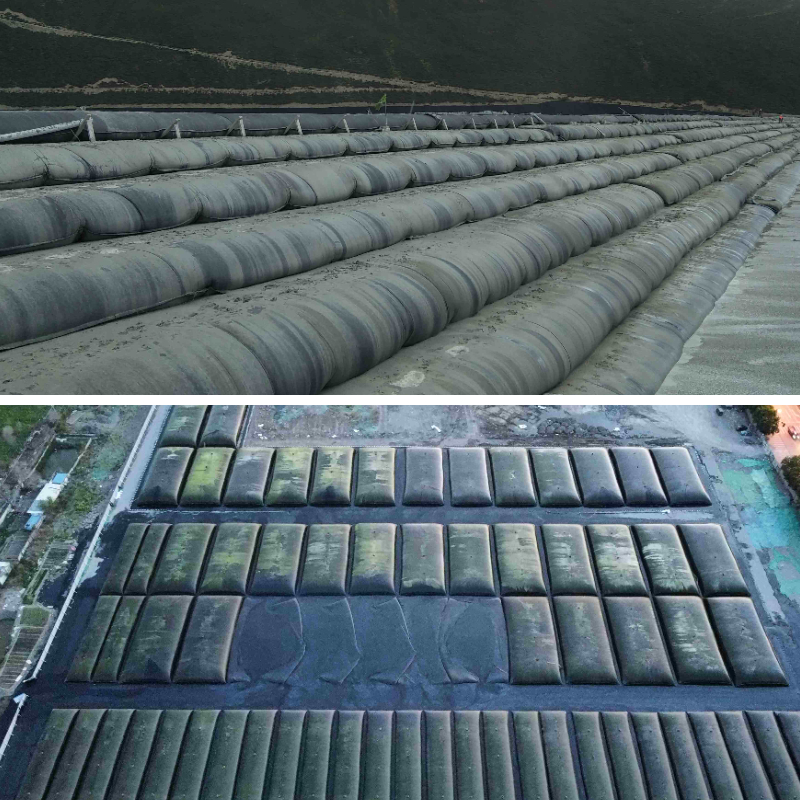

Riverbank erosion threatens communities, farmland, and infrastructure—unaddressed, it motives land loss, flooding, and highly-priced injury to roads or buildings. Traditional fixes like rock riprap or concrete partitions are expensive, labor-heavy, and unsafe to neighborhood ecosystems. Geotextile tubes provide a higher alternative: flexible, porous geosynthetics stuffed with sand, soil, or sediment that manage erosion whilst mixing with nature. Even Coastal Protection Geotextile Tubes—built for harsh coastal conditions—adapt seamlessly to riverbanks, turning in long-lasting stability. Below, we wreck down 5 indispensable steps to use geotextile tubes for riverbank stabilization, from deciding on the proper product to preserving it practical for years.

1. Select the Right Geotextile Tube: Material and Size for Riverbank Conditions

Not all geotextile tubes work for riverbanks—choosing the right one prevents early failure and ensures effectiveness. Start with material: prioritize woven or non-woven polyester or polypropylene. These withstand water, UV rays, and microbial decay—essential for river environments with regular moisture. Coastal Protection Geotextile Tubes are best for riverbanks in tidal zones or high-current areas; they’re engineered to face up to saltwater, wave impact, and intense weather, with more tensile energy (15–25 kN/m) to keep away from stretching or tearing.

Size should fit your river’s drift and erosion severity. For moderate erosion (slow-moving rivers), 1–2 meter diameter geotextile tubes suffice. For average to extreme erosion (fast currents or steep banks), 2–3 meter diameter tubes create a sturdier barrier. Lengths vary from 10–50 meters, however customized sizes in shape irregular banks. Avoid undersized tubes—they shift or crumple below water pressure. Taking time to fit the geotextile tube to your website units up clean geotube set up and long-term success.

2. Prep for Geotube Installation: Site Assessment and Material Checks

Successful geotube set up relies upon on thorough pre-work—skipping this leads to misalignment, bad filling, or tube failure. First, habits a web page assessment: map erosion hotspots (like bends with sturdy currents), measure slope angles (tubes work quality on slopes ≤30 degrees), and take a look at river sediment. Geotextile tubes operate fantastic with sand or sandy soil (30–70% sand content) due to the fact it drains nicely and compacts evenly; sediment grain measurement dictates your filling material.

Next, put together the site: clear particles (rocks, roots, vegetation) to stop punctures. If the financial institution is uneven, add a 5–10 cm layer of compacted sand to create a flat base. Inspect your materials: take a look at the geotextile tube for tears, holes, or defects—small gaps reason sediment leakage all through filling. For Coastal Protection Geotextile Tubes, confirm permeability (10–100 cm/s) suits river conditions: too high, and sediment washes out; too low, and water strain bursts the tube. Gather tools: pumps for filling, hoses, stakes to invulnerable tubes, and a laser stage for alignment. Proper prep cuts delays and ensures your geotextile tube works as intended.

3. Step-by-Step Geotube Installation: Alignment and Secure Filling

Precision in geotube set up maximizes stability—follow these steps to keep away from frequent problems like uneven filling or shifting:

Lay the geotextile tube alongside the erosion-prone bank, centering it on the organized base. For curved banks, use 10–15 meter sections to avoid kinking, and impervious ends with stakes (driven 30–40 cm into soil) to forestall motion whilst filling. Attach a 50–100 psi high-pressure pump to the tube’s filling ports (most have 2–4 ports for even expansion) and use bendy hoses to attain all ports—this prevents bulges or vulnerable spots.

Pump a 70% sand/30% water combination into the tube, filling to 80–90% capacity. Overfilling stretches the fabric; underfilling leaves it inclined to water pressure. Pause each and every 30 minutes to let extra water drain (geotextile tubes are porous) and test alignment with the laser level. Once filled, twist and tie ports tightly, cowl with water resistant tape to quit leaks, and add stakes each 1–2 meters alongside the tube’s size to anchor it. Overlap adjoining tubes by means of 30–50 cm and seal seams with geotextile tape for more stability. For banks with foot visitors or wildlife, optionally cowl the geotextile tube with soil and native vegetation to mixture with the environment. Coastal Protection Geotextile Tubes may additionally want more anchoring (like concrete weights) in excessive currents, however the core system stays the same.

4. Maintain Geotextile Tubes for Long-Term Riverbank Stability

A well-installed geotextile tube lasts 10–15 years, however normal preservation preserves performance. Do quarterly inspections: take a look at for tears, punctures, or sediment leakage, focusing on high-current areas (tube ends, seams). Small tears get patched with geotextile restore cloth and water resistant adhesive; giant injury requires draining the section, repairing the tube, and refilling with sediment.

Monitor sediment levels: over time, compacting or washing out leaves the tube soft. If quantity drops by using greater than 10%, pinnacle up with a sand-water combination by the unique ports. For Coastal Protection Geotextile Tubes in tidal rivers, smooth particles (branches, trash) from the floor each 6 months—debris traps water and will increase cloth pressure.

Protect in opposition to UV damage: most geotextile tubes withstand UV rays, however extended solar publicity degrades fabric. Cover uncovered sections with soil, mulch, or native grasses. Annually test the bank’s slope—if erosion spreads, add a 2d geotextile tube layer or lengthen the present one. With minimal upkeep, your tube continues the riverbank steady for decades.

5. Geotextile Tubes vs. Traditional Methods: Why They’re Better for Riverbanks

Geotextile tubes outperform normal stabilization techniques in cost, efficiency, and eco-friendliness—here’s how:

Cost savings: Rock riprap expenses 15–30 per rectangular foot, whilst geotextile tubes fee 5–12 (including substances and geotube installation). For a 100-meter bank, this saves 10,000–20,000. Coastal Protection Geotextile Tubes are barely pricier (8–15 per rectangular foot) however nevertheless less expensive than concrete partitions (25–40 per rectangular foot).

Faster installation: Geotube set up takes 1–2 days for a 50-meter bank, vs. 1–2 weeks for rock riprap. This cuts disruption to river site visitors and ecosystems.

Eco-friendly: Unlike concrete or rock, geotextile tubes let water and vitamins omit through, assisting aquatic lifestyles and native plants. They additionally use neighborhood sediment, lowering hauling needs. Coastal Protection Geotextile Tubes—designed for sensitive coastal habitats—are equally mild on rivers.

Flexibility: Geotextile tubes adapt to minor bank motion (like flood-related shifting) besides cracking, whilst concrete partitions are inflexible and inclined to breaking. This makes them best for rivers with variable water levels.

Final Thoughts: Geotextile Tubes—Reliable Riverbank Stabilization

Geotextile tubes radically change riverbank stabilization with convenient installation, durability, and eco-friendliness. By deciding on the proper geotextile tube (including versatile Coastal Protection Geotextile Tubes), prepping the web site well, following suitable geotube set up steps, and keeping regularly, you shield towards erosion for years.

Whether stabilizing a small rural river or tidal waterway, geotextile tubes provide a cost-effective, inexperienced choice to standard methods. They show advantageous erosion manage doesn’t damage the environment—helping construct riverbanks that help communities and nature alike.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province