Geocells for Rural Road Maintenance: Cost-Effective Solutions to Fix Potholes and Soil Settlement

Rural roads are the lifeline of agricultural communities, linking farms to markets, properties to schools, and small cities to imperative services. Yet for many rural areas, these roads are trapped in a cycle of decay—potholes shape after each rainstorm, and soil agreement warps pavement till tour will become unsafe. Traditional fixes like asphalt patching or gravel topping solely Band-Aid the problem, lasting 1–2 years earlier than requiring steeply-priced rework. The breakthrough? hdpe geocell technology, which powers durable geocell road systems and proven geoweb soil stabilization—solutions that tackle root causes, now not simply symptoms. Below, we damage down why this innovation is a game-changer for rural avenue maintenance.

1. The Rural Road Crisis: Why Potholes and Soil Settlement Won’t Go Away with Traditional Fixes

Before investing in a solution, it’s imperative to recognize why rural roads war extra than city highways. The problems stem from three unavoidable challenges—ones regular strategies can’t solve:

1.1 Weak, Unreinforced Subgrades: The Hidden Culprit

Most rural roads take a seat on herbal soil (clay, sand, or loam) with no stabilization. When it rains, this soil softens, dropping its capability to guide heavy loads. Tractors, hay trucks, and farm tools (often 10–15 tons) compress the moist soil unevenly, growing voids underneath the pavement. Over time, these voids crumple into potholes. Traditional fixes like asphalt solely cowl the hole—they don’t support the smooth soil below, so potholes return quickly.

1.2 Heavy Loads, Low Traffic: A Double Whammy

Rural roads see fewer cars, however greater heavy-duty vehicles. Unlike city highways, which unfold weight throughout heaps of day by day commuters, rural roads take repeated hits from a small quantity of heavy machines. This centred stress speeds up pavement wear, even on roads with minimal use. Gravel topping, a frequent “quick fix,” washes away or compacts inside months underneath this stress.

1.3 Tight Budgets: No Room for Full Reconstruction

Small counties and rural cities hardly ever have money for full street overhauls. Instead, they count number on patchwork repairs that value $4,000–$6,000 per kilometer annually. This cycle of “fix and fail” wastes cash and leaves roads unsafe. The solely way to damage it is to goal the root issue: unstable soil. That’s where geoweb soil stabilization (powered by hdpe geocell) comes in—it strengthens the subgrade and protects the pavement, ending the cycle for good.

2. HDPE Geocell: The Backbone of Durable Geocell Road Systems

Not all geocells are created equal. For rural roads, hdpe geocell (high-density polyethylene geocell) is the gold standard—it’s constructed to face up to the harsh stipulations of rural life, from excessive temperatures to chemical spills. Here’s why it’s irreplaceable for geocell road projects:

2.1 All-Weather Resilience That Lasts 5–7 Years

Rural roads face brutal weather: sizzling summers that crack asphalt, heavy rains that erode soil, and freezing winters that enlarge moisture. hdpe geocell resists it all: it doesn’t crack beneath UV rays, rot in rain, or wreck down from farm chemical compounds (like fertilizer or diesel spills). Unlike typical fixes that fade in 1–2 years, hdpe geocell maintains its electricity for 5–7 years, decreasing restore frequency.

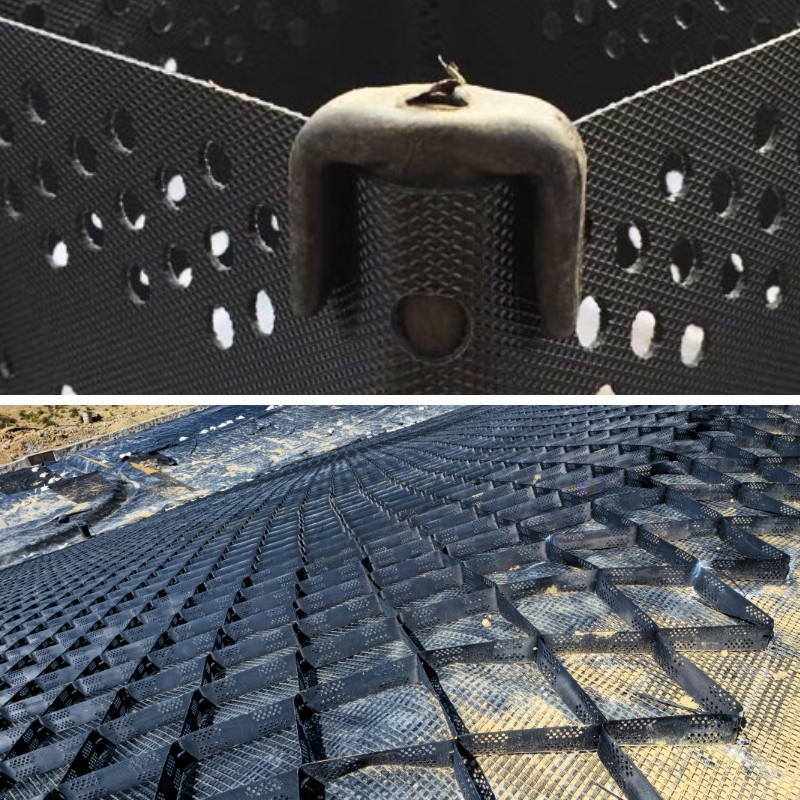

2.2 3D Honeycomb Grid: Maximum Stability for Heavy Loads

Unlike flat geotextiles, hdpe geocell forms a 3D honeycomb grid. When crammed with nearby gravel or beaten stone, this grid locks the mixture in place, developing a inflexible “reinforced layer.” This layer distributes heavy hundreds (like tractors) throughout a wider area, stopping soil compaction and potholes. For geocell road systems, this capacity smoother, safer tour even for farm equipment.

2.3 Easy Installation—No Heavy Machinery Needed

Rural avenue crews regularly lack giant tools like asphalt pavers. hdpe geocell solves this: it comes in light-weight rolls (10–25 meters long) that 2–3 employees can elevate and unroll. No specialised coaching is required—crews can installation it in days, now not weeks. Compare that to ordinary asphalt patching, which wishes heavy vans and closes roads for 4–6 days. hdpe geocell minimizes downtime, retaining farm deliveries on track.

3. Geoweb Soil Stabilization: Ending Soil Settlement for Good

Soil agreement is the “invisible enemy” of rural roads. Even if you restoration potholes, smooth soil underneath the street will hold compacting, growing new bumps and cracks. Geoweb soil stabilization—using hdpe geocell to fortify the subgrade—stops this trouble at the source. Here’s how it works:

3.1 Spreads Weight to Reduce Subgrade Strain by way of 40%

When a heavy truck drives over an unstabilized road, its weight concentrates on a small patch of soil, compressing it over time. Geoweb soil stabilization changes this: the hdpe geocell grid spreads the weight throughout a large area, reducing subgrade pressure by means of up to 40%. This prevents soil compaction, so the avenue doesn’t settle or warp.

3.2 Locks Soil in Place to Prevent Erosion

Sandy or loamy soils (common in rural areas) erode effortlessly all through heavy rains, weakening the road’s foundation. The hdpe geocell grid acts as a barrier, stopping soil from moving sideways or washing away. For roads close to fields or streams, this potential no extra area fall down or surprising potholes after storms.

3.3 Cuts Subgrade Replacement Costs through 30–50%

Traditionally, fixing contract potential digging up ancient soil and changing it with gravel—a method that fees $15,000+ per kilometer. Geoweb soil stabilization eliminates this: you lay hdpe geocell directly over present soil, fill it with neighborhood aggregate, and create a steady foundation. A rural avenue in Oklahoma used this approach and reduce annual preservation expenses by means of $10,000 per kilometer—proving it’s a budget-friendly fix.

4. Cost-Benefit Analysis: Why HDPE Geocell Saves Rural Communities Money

Rural budgets are tight, so each and every greenback counts. hdpe geocell may have a greater upfront fee than regular fixes, however its lengthy lifespan promises big financial savings over time. Let’s examine it to common preservation for a 10km rural road:

4.1 Initial Cost: Higher Upfront, But Worth It

Traditional repairs (asphalt patching + gravel): ~$40,000 for 10km.

hdpe geocell solution: ~$85,000 for 10km.

While hdpe geocell costs greater initially, its lifespan adjustments the math.

4.2 Lifespan: 5–7 Years vs. 1–2 Years

Traditional fixes ultimate 1–2 years, so you’ll want 3–4 repairs over 7 years. hdpe geocell lasts 5–7 years with no most important overhauls. That potential fewer journeys for crews, much less tools use, and no repeated spending.

4.3 7-Year Total Cost: 50%+ Savings

Traditional maintenance: $140,000–$280,000 over 7 years.

hdpe geocell: $85,000 over 7 years.

The financial savings let rural communities make investments in schools, hospitals, or different integral services—all whilst retaining roads safe.

4.4 Less Traffic Disruption = More Farm Revenue

Traditional patching closes roads for 4–6 days per year, delaying farm deliveries to markets. hdpe geocell installation takes 2–3 days total, so vans maintain moving. For a small farm, this capability no misplaced income from spoiled produce or overlooked deadlines.

Conclusion: Invest in HDPE Geocell for Smoother, Cheaper Rural Roads

Rural roads don’t have to be a cycle of potholes, settlement, and wasted money. hdpe geocell—the core of geocell road systems and geoweb soil stabilization—offers a cost-effective, long-lasting solution. It fixes potholes so they remain fixed, stabilizes soil to end settlement, and saves communities cash over time.

Whether you’re a county engineer, farm cooperative leader, or nearby official, hdpe geocell is an funding in your community’s future. Say goodbye to steady repairs—and hiya to rural roads that serve your city reliably, 12 months after year.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province