Geocell FAQs: Lifespan, Load Capacity, and Maintenance

Geocells have flip out to be a go-to reply in civil engineering, construction, and landscaping projects, thanks to their potential to stabilize soil, pork up structures, and prevent erosion. However, many specialists and property owners although have questions about their performance, durability, and upkeep. In this guide, we’ll address the most common FAQs about geocells, focusing on lifespan, load capacity, and maintenance, at the same time as highlighting key variants like geocell HDPE and perforated geocell.

What Is a Geocell, and How Does It Work?

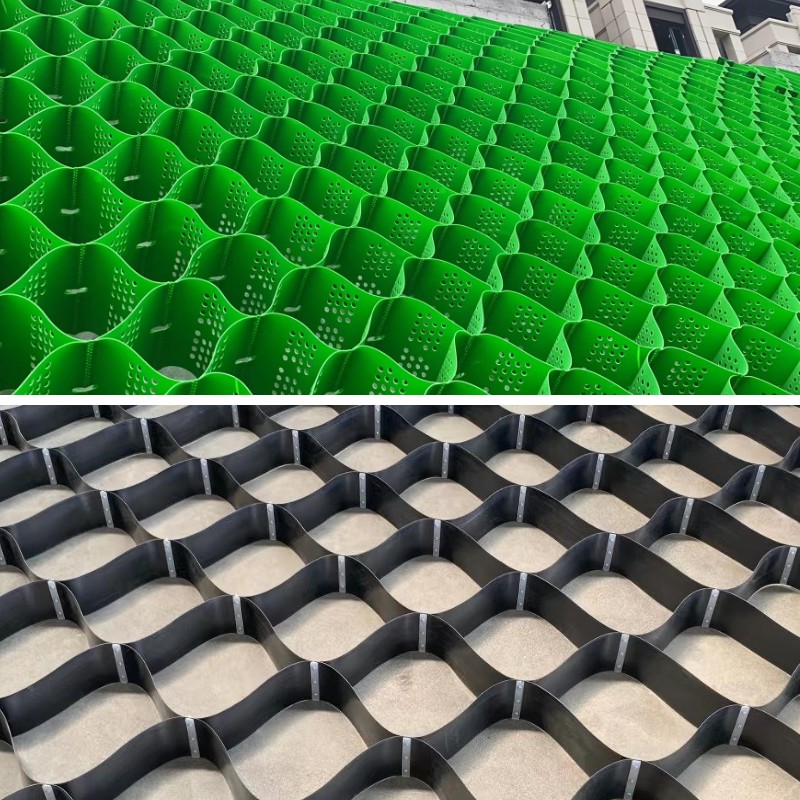

Before diving into specifics, let’s make clear what a geocell is. A geocell is a three-dimensional, honeycomb-like form made from superb polymers, designed to confine and stabilize soil, aggregate, or specific fill materials. When accelerated and filled, the interconnected cells create a rigid framework that distributes heaps evenly, reduces soil movement, and enhances common structural integrity.

Geocell HDPE is a well-known variant, crafted from high-density polyethylene (HDPE), a material considered for its strength, chemical resistance, and flexibility. This makes it nice for heavy-duty functions like avenue constructing and slope stabilization. Meanwhile, perforated geocell factors small holes in the cellular phone walls, allowing for greater water drainage and soil aeration—critical for initiatives in moist or poorly draining areas.

How Long Do Geocells Last? Understanding Lifespan

One of the pinnacle questions about geocells is their lifespan. The reply depends upon on severa factors, inclusive of material quality, environmental conditions, and application.

Material Matters: Geocell HDPE Durability

Geocell HDPE is renowned for its prolonged lifespan, regularly lasting 20 to 50 years or increased in biggest conditions. HDPE is resistant to UV radiation, chemicals, and natural degradation, making it fantastic for every above-ground and buried applications. In contrast, geocells made from lower-grade polymers may additionally additionally degrade faster, particularly when uncovered to direct sunlight hours or harsh chemicals.

Environmental Factors

Exposure to excessive temperatures, moisture, and soil chemistry can have an impact on geocell longevity. For example, in areas with excessive soil acidity, geocell HDPE is favored over one-of-a-kind materials due to its chemical resistance. Perforated geocell can moreover extend lifespan in moist environments through stopping water buildup, which can weaken soil and stress the geocell structure over time.

Installation Quality

Proper set up is key to maximizing lifespan. Geocells have to be efficaciously anchored, stuffed with great materials, and included from sharp objects that may additionally choose to puncture the cells. A well-installed perforated geocell or elegant geocell will preserve its structural integrity for decades, even under normal load.

What Is the Load Capacity of Geocells?

Load manageable refers to the extent of weight a geocell-reinforced form can information barring failure. This varies based totally absolutely on design, material, and fill type, on the other hand geocells are engineered to cope with vast loads.

Geocell HDPE for Heavy Loads

Geocell HDPE is designed for high-load applications. Its rigid form and sturdy cloth allow it to distribute weight at some stage in a massive area, decreasing stress on the underlying soil. In road construction, for example, geocell HDPE can information heavy vehicles, which consists of motors and machinery, through way of stopping rutting and subsidence. Tests showcase that awesome set up geocell HDPE can expand load-bearing workable through the use of 50% or larger in distinction to unreinforced soil.

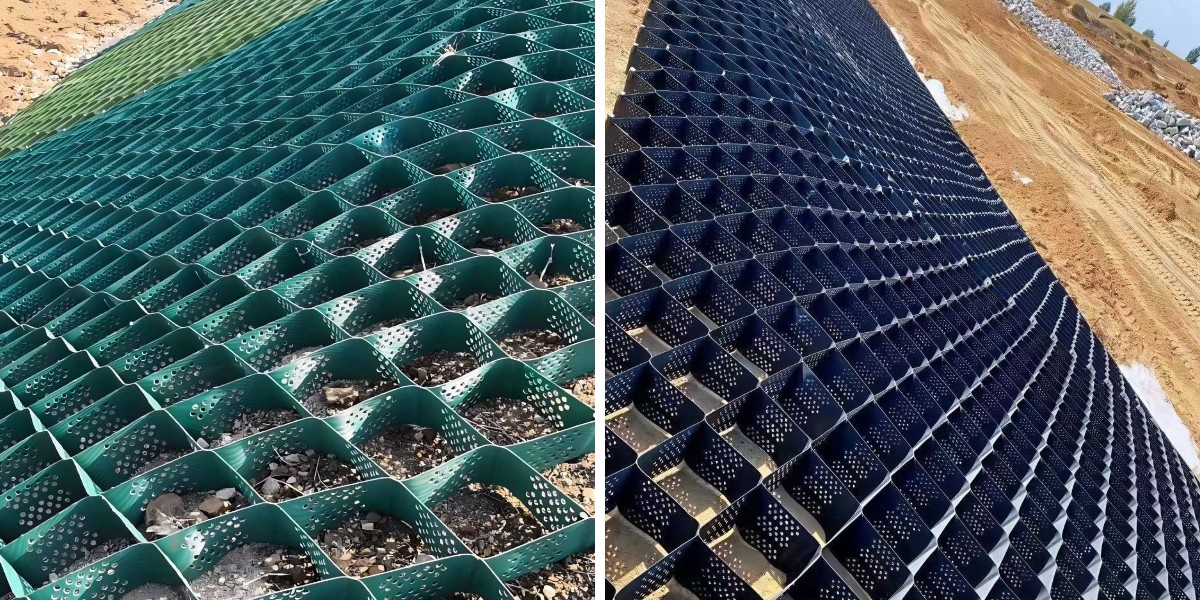

Perforated Geocell and Load Distribution

While perforated geocell is many times chosen for drainage, it moreover presents notable load capacity. The perforations do no longer compromise strength; instead, they help stabilize soil with the resource of allowing greater water to escape, which continues the fill cloth compact and supportive. This makes perforated geocell fantastic for features like parking lots, embankments, and pedestrian walkways, the vicinity every drainage and load useful resource are important.

Factors Affecting Load Capacity

Cell Size and Depth: Larger, deeper cells can accommodate greater fill material, developing load capacity.

Fill Material: Using angular aggregates (like gravel) as an choice of sand improves interlock, enhancing stability.

Soil Type: Geocells feature fine in cohesive soils (clay) or free sands, the region reinforcement is most needed.

How to Maintain Geocells: Tips for Long-Term Performance

Geocells require minimal maintenance, on the other hand proactive care can extend their lifespan and make sure ordinary performance.

Regular Inspections

Inspect geocell-reinforced areas annually, or after immoderate local weather activities (like heavy rain or floods). Look for signs and symptoms and signs of damage, such as:

Punctures or tears in the smartphone partitions (common in areas with sharp rocks or heavy machinery).

Erosion spherical the edges, which can expose the geocell to UV radiation.

Drainage issues, specifically in non-perforated geocells, which can additionally factor out a choose for perforated geocell in future projects.

Addressing Drainage Problems

For non-perforated geocells, horrible drainage can lead to waterlogging and soil weakening. If standing water is observed, suppose about along with drainage pipes or switching to perforated geocell in trouble areas. Perforated geocell naturally reduces water buildup, minimizing the risk of soil erosion and geocell stress.

Repairing Damage

Small tears in geocell HDPE can be repaired the utilization of properly suitable adhesives or patches designed for polymer materials. For massive damage, replacement the affected phase to quit in addition deterioration. Prompt repairs stop soil from escaping the cells, which can compromise load distribution.

Protecting Against UV Exposure

While geocell HDPE is UV-resistant, prolonged publicity to direct daylight hours can then again rationale gradual degradation. In above-ground applications, cowl the geocell with a layer of soil, mulch, or vegetation to guard it from UV rays. This is specially vital for geocells used in slope stabilization or landscaping.

Choosing the Right Geocell: HDPE vs. Perforated

Selecting between geocell HDPE and perforated geocell depends upon on your project’s needs:

Geocell HDPE is best for heavy-load applications, chemical resistance, and long-term sturdiness in varied environments.

Perforated geocell is best for duties requiring drainage, such as wetlands, maintaining walls, or areas with immoderate rainfall.

In many cases, a combination of every can additionally be used—for example, the utilization of geocell HDPE in the base layer for electrical energy and perforated geocell in the pinnacle layer for drainage.

Conclusion

Geocells, which encompass geocell HDPE and perforated geocell, are versatile choices for soil stabilization, load support, and erosion control. Their lifespan tiers from 20 to 50+ years with splendid installation, and their load doable can appreciably outperform unreinforced soil. By understanding protection desires and choosing the proper variant, you can make sure your geocell undertaking elements long-lasting results.

Whether you’re reinforcing a road, stabilizing a slope, or improving drainage, geocells supply a cost-effective, lengthy lasting reply that stands the take a look at of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province