Ditch Lining and Channel Protection Made Easy with Cement Blanket Technology

Introduction: The Persistent Challenge of Ditch Erosion

For farmers, land managers, and civil contractors, keeping the integrity of irrigation and drainage ditches is a constant, expensive battle. Soil erosion compromises water delivery, will increase sedimentation, and leads to significant, routine maintenance. Traditional strategies like concrete pouring or putting in a plastic ditch liner regularly current their personal set of challenges—they are labor-intensive, time-consuming, and can be prone to cracking or displacement. This article explores a groundbreaking alternative: Cement Blanket Technology. This progressive answer is revolutionizing how we strategy channel safety and ditch lining, presenting a durable, rapid, and reasonably-priced reply to a perennial problem.

What is Cement Blanket Technology?

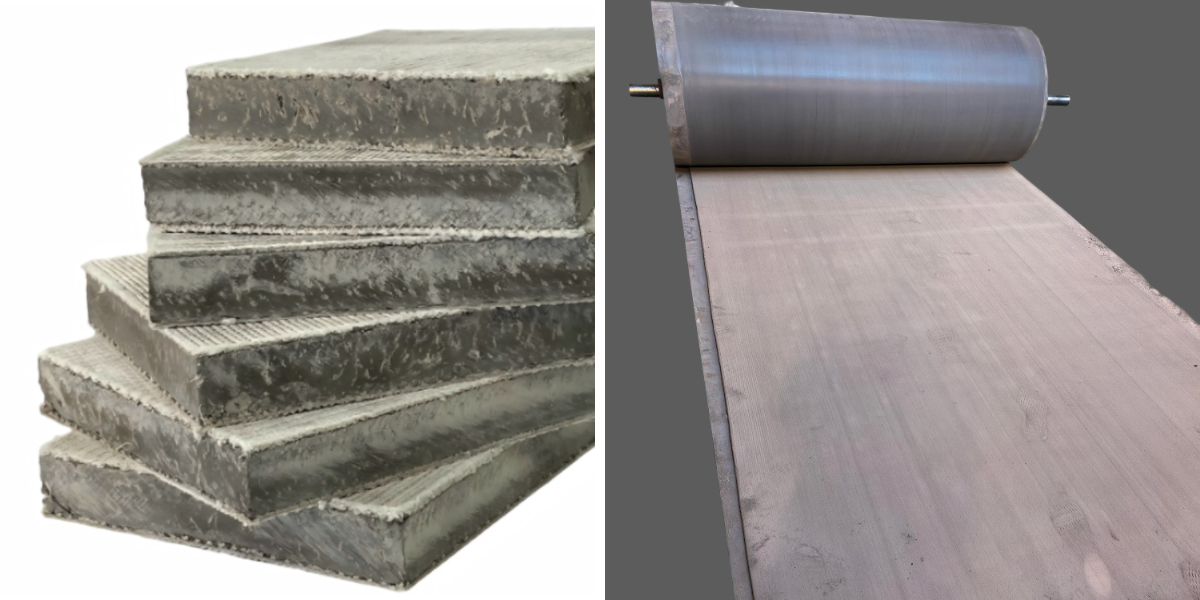

Cement Blanket Technology is a prefabricated, bendy composite mat that transforms into a durable, concrete-like layer upon hydration. Essentially, it is a high-strength, 3-dimensional cloth matrix that is factory-filled with a customized dry cementitious mix. The blanket is delivered to the website in rolls, comparable to a common plastic liner for drainage ditch, but with a integral difference: it will become solid, structural concrete after genuinely being unrolled, positioned, and saturated with water.

The technological know-how eliminates the want for mixing, pouring, or curing moist concrete on-site. It affords instant floor stabilization and, as soon as activated, healing procedures to structure a permanent, erosion-resistant shell that is noticeably resistant to water flow, weathering, and UV exposure. This makes it an tremendously high-quality irrigation ditch liner that combines ease of set up with long-term performance.

The Drawbacks of Traditional Ditch Lining Methods

To respect the innovation of cement blankets, it’s essential to apprehend the boundaries of traditional approaches.

Cast-in-Place Concrete: This technique is relatively labor and material-intensive. It requires forming, mixing, pouring, and prolonged curing times, for the duration of which the website is inclined to weather. It is additionally inclined to cracking due to floor contract or freeze-thaw cycles.

Riprap (Rock Armoring): While effective, riprap can be luxurious to transport and location correctly. It additionally requires a strong geotextile cloth below to forestall soil migration, including any other step. Over time, rocks can settle or be displaced.

Plastic and Flexible Liners: Installing a plastic ditch liner or geomembrane is a frequent fix. However, these substances are inclined to punctures, UV degradation, and can be undermined by using water getting beneath the sheet. They additionally provide no structural electricity and can be hard to anchor securely in high-flow scenarios. Similarly, a skinny plastic liner for drainage ditch might also resolve seepage however regularly fails below mechanical stress or environmental exposure.

Cement Blanket Technology addresses these ache factors directly, providing a most reliable stability of durability, speed, and installational simplicity for tremendous channel protection.

Core Advantages of Cement Blankets for Ditch and Channel Lining

Why is this science gaining speedy adoption throughout agriculture and infrastructure projects? The advantages are multifaceted.

Rapid Installation and Immediate Protection: There is no ready for concrete vans or prolonged curing. Unroll, reduce to shape, hydrate, and the place is stabilized. The blanket gives immediately safety towards erosion from the second it is wetted, with full energy creating inside 24-48 hours. This pace substantially reduces mission timelines in contrast to putting in a regular irrigation ditch liner.

Superior Durability and Strength: Once cured, the cement blanket types a monolithic, high-strength concrete layer. It is fantastically resistant to flowing water, freeze-thaw damage, fire, and UV radiation—issues that regularly plague a fashionable plastic ditch liner. Its strong nature ensures long-term channel safety with minimal maintenance.

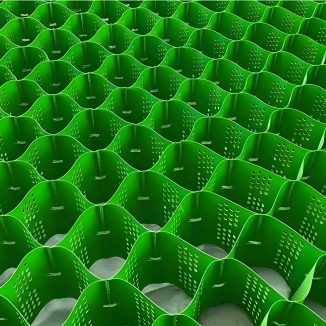

Conformability and Versatility: The bendy nature of the dry blanket approves it to conform flawlessly to irregular contours, slopes, curves, and intersections inside a ditch. This eliminates the complicated forming required for poured concrete and offers a seamless suit that is hard to obtain with inflexible panels or a plastic liner for drainage ditch.

Cost-Effectiveness: While the upfront cloth price may additionally be related to some alternatives, the authentic financial savings come from dramatically decreased labor, equipment, and time on site. There is no want for heavy mixing machinery, forming, or giant crews. The discount in future upkeep and restore similarly enhances the return on investment.

Application Guide: Installing a Cement Blanket Liner

Implementing this science for your ditch lining mission is a simple process.

Site Preparation: Clear the ditch channel of debris, vegetation, and sharp rocks. Excavate and grade the soil to the favored profile. A compacted, clean subgrade is ideal, comparable to the base you would put together for a plastic ditch liner.

Blanket Deployment: Unroll the cement blanket material throughout the working area. It can be without difficulty reduce with utility knives or scissors to suit complicated shapes, junctions, or round inlets. Overlap adjoining rolls by way of a few inches as certain through the manufacturer.

Hydration: Thoroughly soak the blanket with water the usage of a hose or sprinkler system. The material is designed to hydrate evenly. You will see the fabric darken and commence to stiffen inside minutes.

Curing: Allow the activated blanket to cure. It will become walkable inside hours and reaches excessive energy inside a day or two, relying on conditions. Avoid going for walks water thru the ditch at some stage in the preliminary curing period.

This procedure stands in stark distinction to the multi-day, multi-step ordeal of pouring concrete or the refined anchoring manner required for a plastic liner for drainage ditch.

Ideal Use Cases for Cement Blanket Technology

This versatile cloth is appropriate for a broad vary of applications:

Agricultural Irrigation Ditches and Canals: As a everlasting irrigation ditch liner, it minimizes water loss thru seepage and prevents financial institution erosion.

Drainage Channels and Swales: Provides long lasting channel safety in residential, commercial, and municipal drainage systems.

Stormwater Management Conveyances: Lines spillways, outflow channels, and retention basin slopes.

Erosion Control on Slopes: Stabilizes embankments and shores in opposition to runoff erosion.

Pipeline and Utility Trench Protection: Provides a protecting armor layer over buried infrastructure.

Conclusion: A Smart, Future-Proof Investment

For everyone responsible for managing land and water resources, ditch erosion is greater than a nuisance—it’s a risk to productiveness and infrastructure. Cement Blanket Technology gives a modern, clever answer that transcends the barriers of old fashioned strategies and fragile plastic ditch liner products. It grants the everlasting sturdiness of concrete with the easy set up of a roll-out mat.

By deciding on this superior approach for your subsequent channel safety project, you are now not simply putting in an irrigation ditch liner; you are investing in a long time of dependable performance, large time and labor savings, and freedom from steady repair. It makes attaining professional-grade, long-lasting ditch lining and safety genuinely less complicated than ever before. Explore how this revolutionary technological know-how can streamline your operations and impenetrable your waterways for the future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province