Cost-Benefit Analysis: Are Composite Geomembranes More Economical in the Long Run?

Introduction: The True Cost of a Geomembrane is Not Its Price Tag

When specifying a lining machine for a quintessential containment project—be it a landfill, reservoir, or mining facility—the preliminary charge per rectangular meter is frequently the first and most closely weighted factor. This center of attention on upfront fee can lead to the choice of single-ply geomembranes that show up reasonable on paper. However, a simply knowledgeable selection requires a Lifecycle Cost Analysis. This evaluation displays that whilst a Composite Geo-membrane frequently includes a greater preliminary cloth cost, its built-in graph grants substantial, compounding financial savings in installation, performance, and chance mitigation over decades. This article deconstructs the long-term economics, demonstrating why a HDPE Composite Geomembrane or a specialised Landfill Composite Geomembrane is regularly the most comparatively cheap preference over the full undertaking lifecycle.

Deconstructing the Composite Advantage: Built-In Value

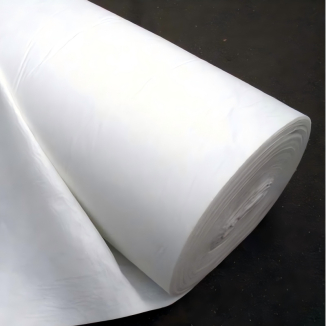

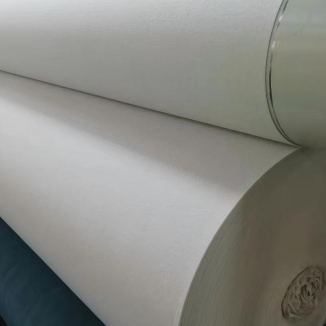

A Composite Geo-membrane is a manufactured laminate, normally bonding a non-woven geotextile to one or each facets of a geomembrane (often HDPE or LLDPE). This synergy creates intrinsic price that a single-ply liner can't match:

The Geotextile Layer gives built-in safety towards punctures from the subgrade or overlying materials. It additionally affords best interface friction for slope balance and can act as a drainage/venting layer.

The Geomembrane Layer (e.g., in a HDPE Composite Geomembrane) affords the primary, sturdy fluid barrier with great chemical resistance.

This integration is no longer simply a feature; it is the supply of long-term savings.

The Cost-Benefit Breakdown: Beyond the Invoice

A complete evaluation should consider 4 key fee pillars: Material, Installation, Long-Term Performance, and Risk.

1. Material Costs: A Misleading Starting Point

Yes, the per-square-meter charge of a Composite Geo-membrane is commonly 20-40% greater than a single-ply geomembrane of equal thickness. Viewing this in isolation is the core mistake. This "premium" purchases the built-in geotextile, disposing of the want to source, handle, and installation it as a separate component. For a challenge like a Landfill Composite Geomembrane cap, this capability one much less cloth to procure and one much less development step.

2. Installation & Construction Savings: Where Savings Accelerate

This is the place composite liners commence to reveal clear financial superiority.

Reduced Subgrade Preparation: The shielding geotextile layer tolerates a less-than-perfect subgrade higher than a naked geomembrane. It cushions in opposition to punctures from small stones or irregularities, probably lowering pricey subgrade ending work.

Faster Deployment and Seaming: The composite rolls out as a single, built-in product. There is no time-consuming, separate placement of a defensive geotextile underlay. For a HDPE Composite Geomembrane, the seaming technique focuses fully on the geomembrane core, however the product's ruggedness approves for quicker panel placement with much less worry of damage.

Enhanced Construction Quality & Survivability: The geotextile face dramatically reduces the danger of puncture at some point of backfilling of drainage stone or waste. Fewer development damages suggest fewer pricey repairs and delays. This robustness is useful on massive websites like landfills, the place the Landfill Composite Geomembrane have to stand up to the placement of heavy drainage geocomposites and cowl soils.

3. Long-Term Performance & Maintenance: The Value of Reliability

A lining system's reason is to contain. Failure is catastrophic. Here, composites excel.

Leak Reduction and Integrity: The major monetary gain of any geomembrane is stopping environmental infection and the astronomical remediation fees that follow. The most effective puncture resistance and safety of a Composite Geo-membrane without delay translate to a lower chance of liner failure over its 30+ yr plan life.

Slope Stability: The excessive interface friction supplied with the aid of the geotextile aspect is a indispensable engineering benefit. It will increase the issue of protection for slopes, stopping luxurious slippage or steadiness disasters that ought to require big remediation. This is non-negotiable for sidewalls in reservoirs or landfills.

Reduced Long-Term Liability: A greater robust, defect-free set up minimizes future monitoring fees and the chance of regulatory penalties or cleanup liabilities—a paramount consideration for owners.

4. Risk Mitigation: The Priceless Factor

Traditional price evaluation frequently ignores risk. In containment, danger is monetary and existential.

Construction Risk: The decreased danger of harm throughout set up maintains the challenge on agenda and budget.

Performance Risk: The engineered security elements in a composite machine (better friction, greater puncture resistance) supply a increased margin towards unexpected stresses, such as contract or seismic activity.

Reputational & Regulatory Risk: A successful, leak-free mission protects the owner's popularity and ensures regulatory compliance. The value of a failure in these areas can dwarf the complete preliminary task budget.

Application Spotlight: The Landfill Composite Geomembrane

The landfill surroundings flawlessly illustrates the long-term economics. Here, the liner is subjected to aggressive subsidence, heavy overburden pressures, and complicated chemical exposure.

On the Base: A Landfill Composite Geomembrane protects the fundamental liner from the underlying clay and drainage layers. It additionally affords imperative venting.

On the Cap: It is the perfect capping solution, presenting a strong barrier towards infiltration whilst its textured floor anchors the overlying cowl soil on steep slopes.

In each cases, the fee of repairing a leak post-closure is truly incalculable, involving excavation thru waste, regulatory hell, and enormous expense. The incremental upfront funding in a composite device is a rational insurance plan coverage in opposition to this scenario.

Conclusion: Investing in Certainty Over Price

The query is not, "Are composite geomembranes cheaper?" however rather, "Which gadget gives the lowest whole value of possession with the absolute best assurance of success?"

A rigorous cost-benefit evaluation persistently indicates that for demanding, everlasting containment applications, a Composite Geo-membrane—whether a general-purpose HDPE Composite Geomembrane or a specialised Landfill Composite Geomembrane—is the extra reasonably-priced desire in the lengthy run. The greater preliminary cloth price is offset and then surpassed by way of financial savings in simplified construction, decreased hazard of delay, top-quality established performance, and dramatically decrease lifecycle risk.

When the actual fee of failure is considered, the composite is now not an expense; it is a strategic funding in task integrity, regulatory compliance, and monetary predictability. For engineers and proprietors who fee long-term cost over non permanent savings, specifying a composite geomembrane is the most financially sound decision.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province