Concrete Impregnated Fabric for Rapid Deployment Shelters and Housing

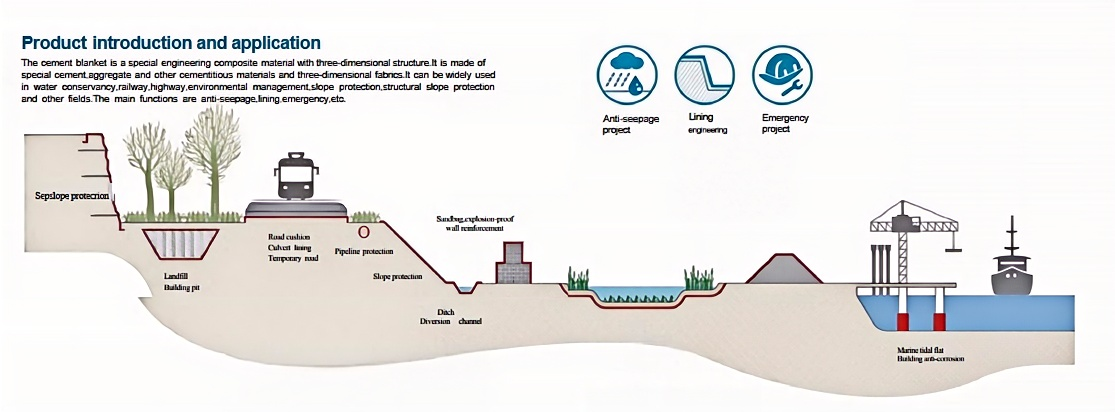

In crises—whether herbal disasters, humanitarian emergencies, or brief housing needs—speed, durability, and affordability are non-negotiable. Traditional development strategies for shelters and housing are slow, labor-intensive, and frequently require scarce materials, leaving inclined populations barring secure lodging for weeks or months. Concrete impregnated cloth has emerged as a transformative solution, redefining how we construct rapid-response shelters. Also recognized as concrete cloth, this revolutionary fabric combines the power of concrete with the portability of fabric, enabling fast, resilient construction. Its Fast-Setting Concrete Cloth editions take effectivity further, hardening shortly to supply instant protection. This information explores how concrete impregnated cloth revolutionizes speedy deployment housing, its key advantages for emergency and brief use, set up first-rate practices, and why it’s turning into the go-to preference for corporations and builders worldwide.

The Limitations of Traditional Rapid Shelter Solutions

Traditional speedy shelters—such as tents, metallic shanties, or wood-framed structures—fall quick in crucial areas:

Lack of Durability: Tents are susceptible to tearing, waterlogging, and harm from wind or pests, providing solely non permanent protection. Metal and wooden buildings may additionally rust, rot, or cave in beneath harsh conditions.Slow Deployment: Even "rapid" usual builds require knowledgeable labor, heavy equipment, and transporting cumbersome materials—luxuries in catastrophe zones with broken infrastructure.Poor Weather Resistance: Tents leak in rain, overheat in sun, and fail in excessive winds. Metal buildings habits warmness and cold, making them uncomfortable year-round.Environmental Impact: Disposable tents create waste, whilst wooden buildings make contributions to deforestation in prone regions.

These gaps demand a answer that’s quick to deploy, durable, weather-resistant, and sustainable—qualities that concrete impregnated cloth gives you effortlessly.

Why Concrete Impregnated Fabric Excels for Rapid Housing

Concrete impregnated material is a composite material: a bendy material matrix (typically glass fiber or polyester) infused with a dry concrete mix. When activated with water, the concrete hydrates and hardens into a rigid, load-bearing structure. For fast deployment, its special houses set it apart:

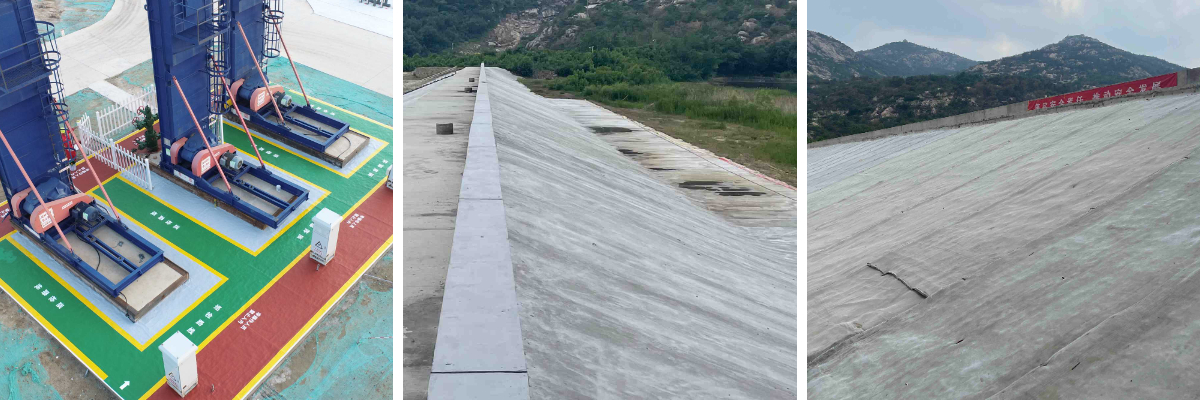

Portability: Rolled up, concrete fabric is light-weight and compact—one roll can cowl sufficient region for a small shelter, but suits in a general vehicle. This eliminates the want for heavy transport, necessary in areas with restrained access.Speed: Fast-Setting Concrete Cloth hardens in hours, now not days. A small crew can erect a simple refuge in beneath 24 hours, from unboxing to occupancy.Durability: Once hardened, it’s resistant to wind, rain, fire, and pests. Unlike tents, it doesn’t degrade in UV mild and can ultimate 5–10 years with minimal maintenance.Weather Resilience: It’s waterproof, thermally insulating, and structurally sound in severe temperatures—keeping occupants dry in monsoons, cool in deserts, and heat in bloodless climates.

Key Applications: From Emergency Shelters to Temporary Housing

Concrete impregnated cloth is versatile sufficient to meet numerous speedy housing needs, from instant disaster response to semi-permanent communities:

1. Disaster Emergency Shelters

After earthquakes, floods, or hurricanes, displaced households want safe haven fast. Fast-Setting Concrete Cloth is deployed by way of alleviation agencies to create instant, weatherproof shelters. Teams unroll the cloth over a easy body (or even immediately on degree ground), spray it with water, and inside hours, it hardens into a secure space. These shelters defend towards the factors and grant privacy, a imperative morale raise for survivors. Unlike tents, they don’t crumple in excessive winds or floodwaters, making them best for post-disaster zones.

2. Humanitarian Camps

Refugee or internally displaced man or woman (IDP) camps require shelters that closing longer than tents however are nonetheless speedy to build. Concrete impregnated material creates semi-permanent housing that can accommodate households for years. The fabric’s sturdiness reduces the want for regular replacements, whilst its thermal insulation improves dwelling conditions. Camps constructed with concrete material are additionally greater equipped and resilient, with shelters that withstand hearth and pest infestations—common troubles in tent camps.

3. Temporary Construction Housing

Construction crews working in far off areas (e.g., highways, mines, or oil fields) want on-site housing that’s quick to set up and durable. Concrete impregnated cloth shelters are erected in days, offering comfy lodging for workers. They stand up to harsh job-site conditions, from dirt storms to heavy rain, and can be dismantled (or left for future use) when the task ends. This reduces the price and environmental influence of transporting regular constructing materials.

4. Rural and Off-Grid Housing

In rural areas with constrained get right of entry to to building resources, concrete material affords an low-cost housing solution. Local communities can build residences the use of minimal equipment and skills—no want for masons or heavy equipment. The fabric’s water activation works with even confined water supplies, and its sturdiness skill houses stand up to rural challenges like termites and excessive weather. This empowers communities to construct their personal housing, fostering self-sufficiency.

Installation Guide: Fast-Setting Concrete Cloth for Rapid Shelters

The simplicity of putting in concrete impregnated cloth is phase of its appeal. Even untrained groups can grasp the process:

1. Site PreparationChoose a level, well-drained area

Clear debris, rocks, and vegetation to create a clean base. For primary shelters, no body is needed—just make certain the floor is flat. For large or taller structures, construct a easy body the use of nearby substances like bamboo, wood, or metallic poles. The body helps the cloth and defines the shelter’s form (e.g., A-frame, rectangular).

2. Unroll and Position the Fabric

Unroll Fast-Setting Concrete Cloth over the body or ground. Cut the cloth to dimension the usage of a utility knife, leaving overlaps of 15–20 cm at seams for a watertight seal. Ensure the material is taut however no longer stretched—this prevents cracking as it hardens. For multi-panel shelters, overlap the edges and press them collectively to fuse at some stage in hydration.

3. Activate with Water

Spray or pour water evenly over the complete cloth surface. Use a backyard hose, bucket, or even a spray bottle for small areas. The material will soak up water, activating the concrete mix. Ensure each area is completely wetted—dry spots will now not harden properly. Fast-Setting Concrete Cloth commonly starts offevolved hardening inside 1–2 hours and reaches full power in 24 hours.

4. Finish and Customize

Once hardened, add ending touches like doorways (using cloth or wood), home windows (cut openings and cowl with clear plastic), or insulation (add a layer of foam if needed). For longer-term use, practice a concrete sealant to beautify water resistance and durability. The refuge is now equipped for occupancy—no ready for weeks of curing like normal concrete.

Conclusion: Concrete Impregnated Fabric—The Future of Rapid Housing

Concrete impregnated fabric, from concrete material to Fast-Setting Concrete Cloth, is altering the sport for speedy deployment shelters and housing. Its special combination of speed, durability, portability, and affordability addresses the failings of regular solutions, making it fundamental in crises and beyond.

For remedy organizations, building companies, and communities in need, this cloth isn’t simply a constructing product—it’s a lifeline. It affords safe, dignified housing when time is of the essence, reduces environmental impact, and empowers human beings to rebuild quickly. As local weather alternate will increase the frequency of failures and world housing desires grow, concrete impregnated cloth will stay at the forefront of innovative, compassionate construction. Invest in this technology, and you’re no longer simply constructing shelters—you’re constructing hope and resilience for these who want it most.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province