Circular Economy & HDPE Geomembrane: Recycling & Reusing Liners for Reduced Waste

In the world pursuit of sustainable development, the round financial system has emerged as a pivotal method to reduce waste and maximize useful resource efficiency. Within this framework, high-performance substances that aid recycling and reutilization are gaining remarkable attention. HDPE geomembrane, a versatile and long lasting artificial liner, stands out as a key participant in bridging round economic system dreams with sensible engineering applications. From environmental safety tasks to industrial containment systems, HDPE geomembrane liners no longer solely supply dependable impermeability however additionally provide huge plausible for recycling and reusing—effectively decreasing the environmental footprint of development and industrial activities. This article explores the intrinsic hyperlink between HDPE geomembrane and round economy, focusing on recycling technologies, sensible reuse cases, and the quintessential function of expert geomembrane set up in improving aid circularity.

1. Why HDPE Geomembrane Is a Perfect Fit for Circular Economy

The round economic system emphasizes "reduce, reuse, recycle" to change the typical linear "take-make-dispose" model. HDPE geomembrane aligns with this philosophy due to its special fabric residences and lengthy provider life, making it a sustainable desire for quite a number containment applications. Unlike single-use or low-durability substances that generate vast waste, HDPE geomembrane liners are engineered to stand up to harsh environmental conditions, chemical corrosion, and UV exposure—extending their provider existence to 40-60 years in acceptable functions . This toughness at once reduces the frequency of replacement, minimizing the quantity of waste generated in the first place.

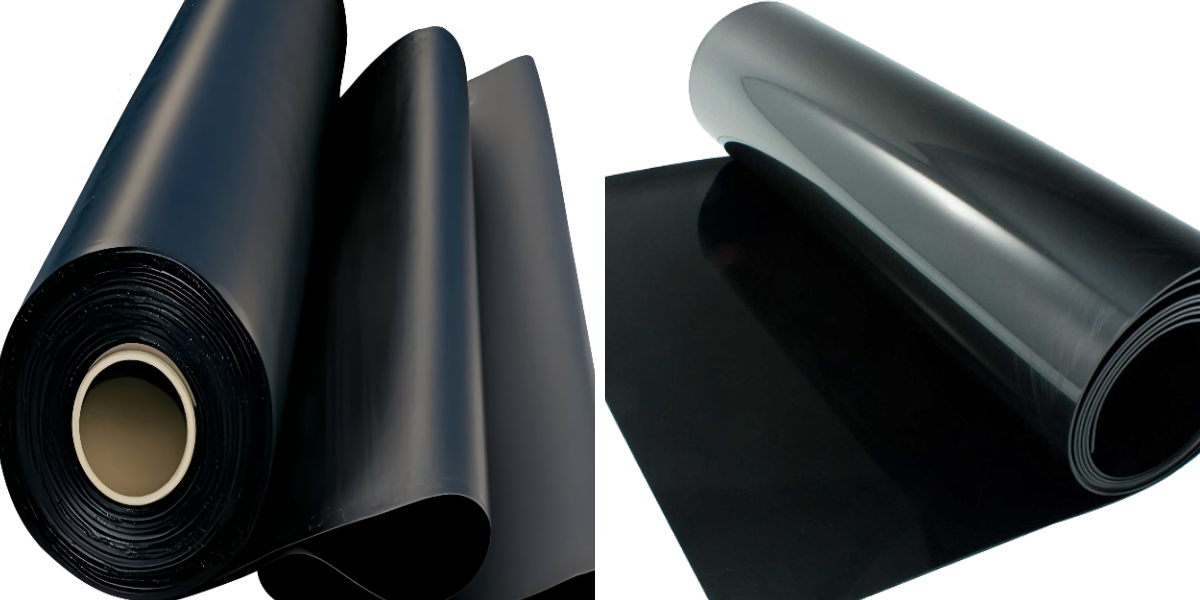

Another key gain of HDPE geomembrane is its recyclable nature. Composed of 97.5% high-density polyethylene resin with minimal components (such as carbon black for UV stability), HDPE geomembrane can be efficaciously processed and reused after its carrier existence . Compared to usual waterproofing substances like compacted clay, HDPE geomembrane has a 3-times decrease carbon footprint, as it requires much less electricity and sources for manufacturing and transportation . For example, a 1.5mm thick HDPE geomembrane achieves the equal watertight effect as 0.6m of first-rate compacted clay, whilst decreasing carbon dioxide emissions considerably for the duration of the manufacturing manner . These homes make HDPE geomembrane a low-impact, resource-efficient cloth that flawlessly helps round economic system objectives.

2. Recycling & Reusing Technologies of HDPE Geomembrane Liners

The recycling and reusing of HDPE geomembrane liners are supported with the aid of mature applied sciences and sensible cases, turning waste liners into treasured resources. The technique normally includes collection, cleaning, processing, and remanufacturing—forming a closed-loop machine that minimizes cloth loss. Two major recycling strategies dominate the industry: physical recycling and chemical recycling, every with special benefits and applications.

2.1 Physical Recycling: The Mainstream Approach for Industrial Reuse

Physical recycling is the most extensively adopted technique for HDPE geomembrane, involving mechanical processing besides altering the material's chemical structure. The procedure starts offevolved with accumulating waste HDPE geomembrane liners from development websites (such as landfills, mining tailings ponds, and oil drilling pads). These liners are then sorted to dispose of non-HDPE contaminants (like geotextile composites or metallic fasteners) . After sorting, the liners are shredded into small pieces, cleaned to do away with soil, chemicals, and different impurities, and then melted and granulated . The ensuing HDPE regranulate can be used to produce new HDPE geomembrane liners (for much less stressful applications) or different plastic merchandise such as building substances and packaging.

A great instance of bodily recycling is the HDPE geomembrane recycling application in Pennsylvania's Marcellus Shale oil and gasoline fields. Since 2010, over ninety million kilograms of geomembrane have been mounted in these fields for nicely pad liners, containment ponds, and secondary containment structures . A committed recycling entity collects and tactics these waste liners, diverting at least 1.1 million kilograms of geomembrane from landfills yearly . The recycled HDPE is then reused in the manufacturing of new liners and industrial components, developing a closed-loop aid device for the oil and fuel industry.

2.2 Chemical Recycling: Advanced Solution for Contaminated Liners

For HDPE geomembrane liners closely contaminated with chemical compounds or tough to separate from composites, chemical recycling provides an tremendous solution. This technique breaks down the polyethylene polymer into its primary monomers or hydrocarbon fractions via tactics like solvent separation or thermal cracking . Solvent separation makes use of particular solvents to selectively dissolve the HDPE component, reaching high-purity separation from composites . Thermal cracking, on the different hand, decomposes HDPE into gas or chemical uncooked substances underneath anaerobic high-temperature conditions, which can be used to produce new plastics or electricity .

Advanced applied sciences like Gneuss' "Super Clean Process" have similarly more advantageous the feasibility of HDPE chemical recycling. This device makes use of environment friendly degassing and ultra-fine filtration to take away risky contaminants and challenging impurities from recycled HDPE, producing extraordinary regranulate that meets meals contact requirements . Such applied sciences enlarge the recycling scope of HDPE geomembrane liners, even these used in harsh industrial environments with heavy contamination.

2.3 Reuse Cases: Extending Liner Life in Practical Applications

In addition to recycling, direct reuse of HDPE geomembrane liners is some other high-quality way to promote round economy. Well-maintained liners can be eliminated from achieved tasks and reinstalled in less disturbing applications. For instance, HDPE geomembrane liners used in transient development containment ponds can be reused in agricultural irrigation ponds or ornamental water facets after inspection and repair.

A profitable reuse case is the biogas mission in Malaysia, which procedures palm oil mill effluent (POME) to generate renewable energy. The mission at the start used 9,290 m² of 1.0mm HDPE geomembrane as the fundamental barrier for POME ponds and 1.5mm HDPE geomembrane as floating covers to seize methane . After the preliminary venture phase, the well-preserved HDPE geomembrane liners had been reused in the enlargement of the biogas facility, decreasing the want for new cloth manufacturing and reducing the project's carbon footprint . This reuse exercise now not solely saves charges however additionally maximizes the aid cost of HDPE geomembrane.

3. Geomembrane Installation: A Critical Factor for Enhancing Recyclability

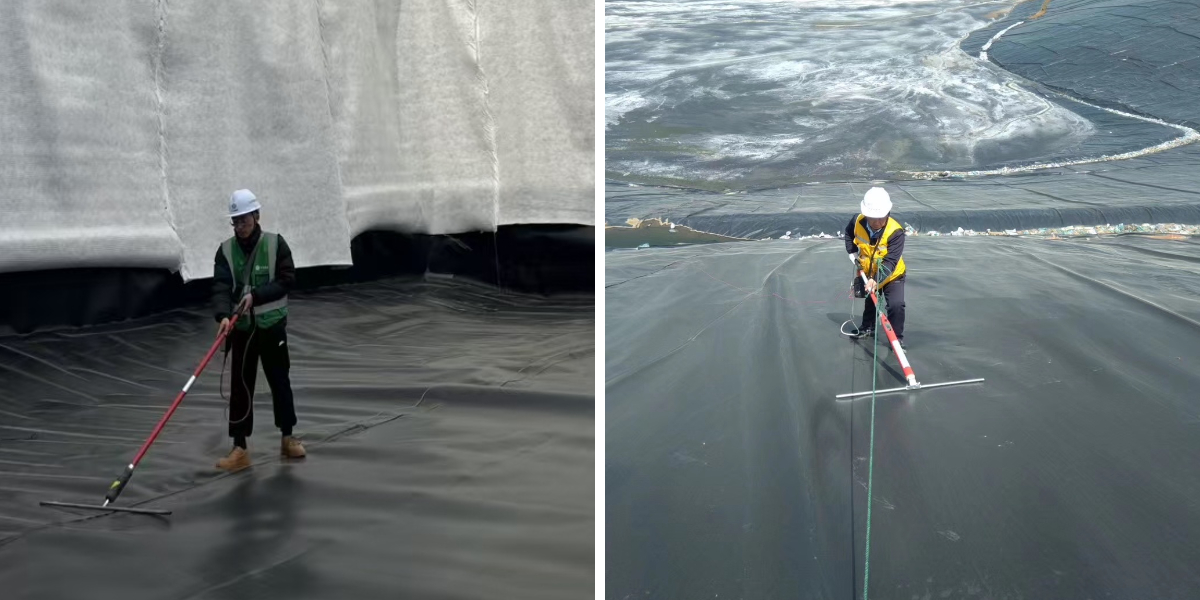

The recyclability and reusability of HDPE geomembrane liners are carefully linked to the fine of geomembrane installation. Improper set up can lead to untimely damage, decreased provider life, and improved issue in recycling. Professional geomembrane set up ensures that the liner keeps its structural integrity for the duration of its provider life, laying the basis for nice recycling and reuse.

Key set up practices that decorate recyclability include: 1) Proper subgrade preparation: Ensuring a smooth, compacted subgrade to keep away from punctures and tears in the HDPE geomembrane . 2) High-quality seam welding: Using thermal bonding methods that meet GRI-GM 19 requirements to make certain seamless joints, lowering leakage dangers and stopping liner harm from chemical erosion . 3) Protection layer installation: Applying non-woven geotextiles or soil cushions to guard the HDPE geomembrane from mechanical harm for the duration of and after set up . 4) Wrinkle management: Minimizing wrinkles at some point of set up to keep away from stress concentrations that can lead to cloth fatigue .

Rigorous building best assurance (CQA) checking out is additionally indispensable for geomembrane installation. Pre-service testing, along with fabric verification and seam energy testing, ensures that the set up HDPE geomembrane liner meets overall performance requirements . For example, unfavorable trying out of seams (measuring peel and shear strength) and non-destructive checking out (such as air stress testing) make certain that the liner is free from defects . A well-installed HDPE geomembrane liner now not solely performs better in containment purposes however additionally stays intact and recyclable after its carrier life.

Conclusion: Embracing HDPE Geomembrane Recycling for a Sustainable Future

HDPE geomembrane performs a quintessential function in advancing the round economic system in the development and environmental safety industries. Its recyclable properties, lengthy carrier life, and various reuse practicable make it a low-waste, resource-efficient material. By adopting mature recycling applied sciences (physical and chemical recycling) and promotion direct reuse practices, we can appreciably decrease the environmental influence of HDPE geomembrane liners.

Moreover, expert geomembrane set up is a imperative prerequisite for maximizing the recyclability of HDPE geomembrane. Investing in applicable set up and first-class assurance ensures that the liner continues its integrity, extending its carrier existence and facilitating environment friendly recycling. As the world demand for sustainable substances grows, the recycling and reusing of HDPE geomembrane liners will proceed to reap momentum, contributing to a extra round and environmentally pleasant future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province