Cement Blanket vs. Shotcrete: When to Choose Each for Slope Stabilization & Repairs

Slope stabilization and infrastructure repairs are indispensable for mitigating erosion, preventing landslides, and safeguarding each residential and business residences in high-risk terrain. Two of the most extensively used options in geotechnical engineering are cement blanket (also acknowledged as cement canvas) and shotcrete. While each serve the core purpose of reinforcing slopes and repairing broken structures, their special properties, set up processes, and value profiles make them higher proper for precise scenarios. In this guide, we damage down 4 key elements to assist undertaking managers, engineers, and contractors figure out between cement blanket and shotcrete for their slope stabilization and restore needs.

1. Installation Complexity & Time Efficiency

The velocity and ease of set up can make or ruin a slope stabilization project, particularly in emergency situations like post-storm erosion or drawing close landslide threats. Here, cement blanket (and its interchangeable counterpart, cement canvas) and shotcrete diverge dramatically in their implementation requirements.

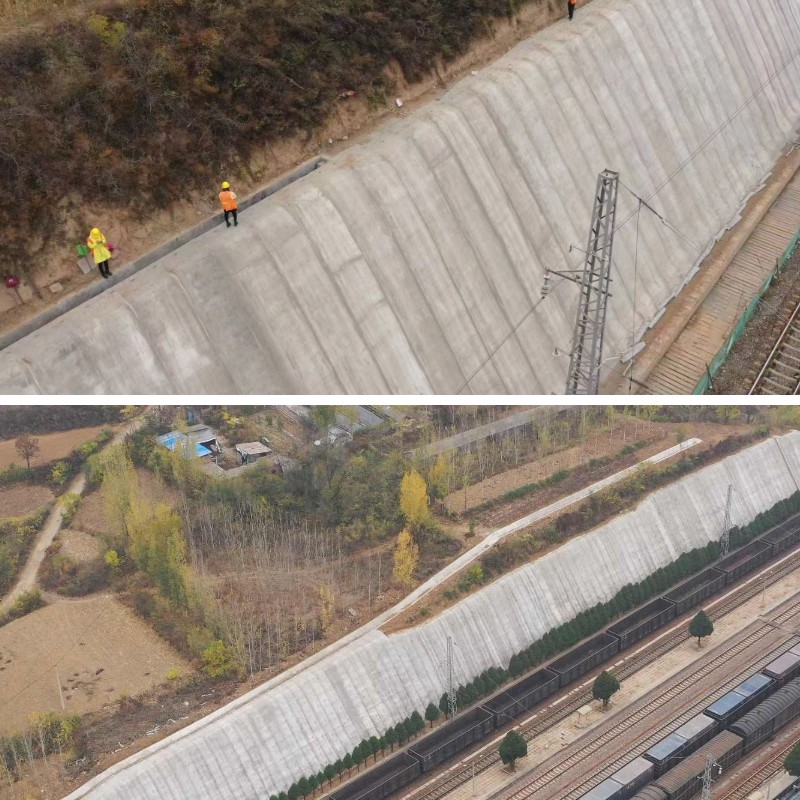

Cement blanket/cement canvas is a prefabricated, bendy geosynthetic cloth infused with dry cement. Its set up system is remarkably straightforward: the fabric is unrolled or draped at once over the goal slope or broken area, secured with anchors or stakes, and then activated via spraying or soaking with water. Once hydrated, the cement blanket hardens into a durable, water resistant concrete layer that conforms to the terrain’s herbal contours. Because it arrives pre-mixed and requires no on-site concrete batching, set up groups can entire tasks in hours as an alternative than days—even with restricted manpower. For example, a small-scale slope restore that would possibly take a shotcrete crew 2-3 days may want to be completed in a single shift with cement canvas.

Shotcrete, via contrast, includes pumping a moist concrete combination (or dry combine with water brought at the nozzle) at excessive stress onto the slope or restore site. Its set up needs specialised gear (shotcrete pumps, air compressors) and a skilled crew, together with nozzle operators who need to skillfully direct the fabric to make certain uniform insurance and adhesion. The technique additionally requires floor preparation: slopes have to be cleared of debris, and in some cases, strengthened with rebar or wire mesh to improve structural integrity. This adds time and complexity—shotcrete initiatives regularly require 1-2 days of setup alone, plus extra time for curing (typically 7-14 days for full strength). While shotcrete can be utilized to vertical or overhead surfaces (a advantage for positive repairs), its longer set up timeline makes it much less perfect for emergency or fast-track projects.

2. Site Accessibility & Terrain Adaptability

Many slope stabilization and restore initiatives manifest in faraway or hard-to-reach areas, the place heavy tools can't without problems navigate. The adaptability of cement blanket vs. shotcrete to difficult terrain is a defining thing in their suitability.

Cement blanket/cement canvas excels in areas with restricted access. Its lightweight, rollable structure ability it can be transported to faraway slopes with the aid of pickup truck, ATV, or even carried by way of hand—no want for massive vehicles or heavy machinery. Once on-site, it can be draped over uneven terrain, steep slopes (up to 70 stages in some cases), and even round current constructions (like maintaining partitions or tree roots) besides requiring enormous grading or modification. This adaptability is in particular precious for mountainous regions, forested slopes, or coastal areas the place street get right of entry to is restricted. For instance, a coastal bluff restore assignment that requires crossing slender trails would be some distance greater possible with cement canvas, as it avoids the logistical headache of hauling shotcrete tools to a secluded site. Additionally, due to the fact cement blanket conforms to herbal contours, it continues the slope’s drainage patterns, decreasing the chance of water pooling and in addition erosion—an benefit over shotcrete, which can create flat, impermeable surfaces that lure water if now not desirable sloped.

Shotcrete is a long way much less adaptable to inaccessible or rugged terrain. Its reliance on heavy pumps and compressors capability it is confined to web sites with car get right of entry to for gear transport and setup. Steep slopes or uneven floor might also require brief scaffolding or get admission to systems to function the nozzle operator safely, including value and logistical hurdles. Shotcrete additionally struggles to conform to exceedingly irregular surfaces except widespread floor smoothing, which can disrupt the slope’s herbal drainage and ecosystem. In faraway areas, the price of transporting tools and substances can skyrocket—for example, a mountain slope assignment would possibly require constructing brief roads to go shotcrete gear, which can double or triple assignment charges and lengthen timelines. While shotcrete works properly for accessible, uniform surfaces (like holding wall repairs in city areas), it is now not realistic for most off-grid or rugged terrain.

3. Cost-Benefit Analysis & Long-Term Durability

Budget constraints and long-term overall performance are pinnacle priorities for any engineering project. Comparing the upfront and ongoing charges of cement blanket and shotcrete, alongside with their durability, helps groups stability momentary charges with long-term value.

Cement blanket/cement canvas has a aggressive upfront price structure, even though its per-square-foot cloth charge is frequently greater than uncooked shotcrete mix. However, the financial savings in labor, equipment, and set up time extra than offset this premium. Because cement blanket requires no specialised equipment or giant crews, labor charges are appreciably reduced—small tasks can be accomplished with 2-3 workers, whereas shotcrete commonly wishes a crew of 4-6. Additionally, cement blanket treatment plans quicker (reaching 80% electricity in 24 hours) than shotcrete, that means the slope can be put lower back into provider sooner, minimizing downtime for adjoining residences or infrastructure. In phrases of durability, a suitable set up cement canvas can remaining 15-20 years in average environments, with resistance to UV radiation, freeze-thaw cycles, and chemical corrosion (when paired with shielding additives). Its flexibility additionally approves it to stand up to minor floor motion except cracking, a frequent trouble with inflexible shotcrete. The solely ongoing price is occasional inspection and minor repairs (e.g., patching small cracks), making it a low-maintenance choice for long-term slope stabilization.

Shotcrete has a decrease upfront cloth cost, as concrete is a extensively available, inexpensive commodity. However, its standard undertaking value is frequently greater due to gear rental, specialised labor, and floor training expenses. For example, renting a shotcrete pump can price $500-$1,000 per day, and hiring licensed nozzle operators instructions top class wages. Shotcrete additionally requires longer curing time, which delays assignment completion and may additionally require brief stabilization measures (like erosion manage blankets) to shield the website at some stage in curing—adding greater costs. In phrases of durability, shotcrete is extraordinarily strong when excellent applied, with a lifespan of 20-30 years in most environments. Its inflexible shape presents most advantageous load-bearing capacity, making it best for high-traffic or high-stress areas (like dual carriageway embankments or industrial property slopes). However, shotcrete is susceptible to cracking if the slope shifts or settles, which can lead to water infiltration and similarly damage. Repairs to cracked shotcrete are labor-intensive and costly, as they regularly require chipping away broken areas and re-spraying the material.

4. Environmental Impact & Sustainability

As the development enterprise shifts towards eco-friendly practices, the environmental footprint of slope stabilization substances has come to be a key decision-making factor. Cement blanket and shotcrete vary considerably in their useful resource utilization and ecological impact.

Cement blanket/cement canvas is a greater sustainable choice for a number of reasons. First, it makes use of 50-70% much less cement than regular concrete or shotcrete for equal coverage, as the pre-infused cement is evenly allotted and requires no extra cloth to acquire structural integrity. This reduces the carbon footprint related with cement manufacturing (a main source of international greenhouse gasoline emissions). Second, its dry, pre-mixed structure eliminates on-site concrete batching, which cuts down on dust, noise, and water pollution—critical for touchy ecosystems like wetlands or forested slopes. The water activation procedure additionally makes use of much less water than shotcrete, which requires giant volumes of water for mixing and cleanup. Additionally, cement canvas can be hooked up except casting off native vegetation (e.g., small shrubs or grass) in some cases, retaining the slope’s herbal habitat and stopping soil disturbance. For initiatives in environmentally covered areas, cement blanket’s reduced impact set up makes it the favored preference to comply with regulatory requirements for ecosystem preservation.

Shotcrete has a large environmental footprint due to its excessive cement content material and on-site mixing. The manufacturing of shotcrete’s concrete combine requires tremendous quantities of sand, gravel, and cement, depleting herbal aggregates and growing carbon emissions. On-site mixing additionally generates dirt and runoff, which can contaminate close by soil and water sources—especially frustrating for tasks close to streams or groundwater aquifers. The heavy gear used for shotcrete set up additionally contributes to air and noise pollution, disrupting natural world in far off areas. While some shotcrete mixes can include recycled aggregates or supplementary cementitious substances (like fly ash) to minimize environmental impact, these adjustments add value and may additionally compromise strength. Overall, shotcrete is much less sustainable for tasks with strict environmental policies or a focal point on low-carbon construction.

Conclusion: Choosing the Right Solution for Your Project

Cement blanket (cement canvas) and shotcrete every provide special advantages for slope stabilization and repairs, and the exceptional desire relies upon on your project’s timeline, website online conditions, budget, and environmental goals. For fast, low-access, eco-friendly initiatives (especially emergencies or far flung terrain), cement blanket is the clear winner—its ease of installation, terrain adaptability, and low upkeep make it a versatile, within your budget option. For high-strength, long-term tasks in available areas (like city embankments or heavy-load maintaining walls), shotcrete’s strong structural capability justifies its greater fee and longer timeline.

Whether you’re prioritizing speed, sustainability, or load-bearing strength, consulting a geotechnical engineer to examine your site’s precise wishes will make sure you choose the best fabric to guard your slopes and infrastructure for years to come. If you’re searching to supply amazing cement blanket or cement canvas for your subsequent project, attain out to our group of specialists for tailor-made tips and set up support.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province