Case Studies: Successful Structural Strengthening with Concrete Impregnated Fabric

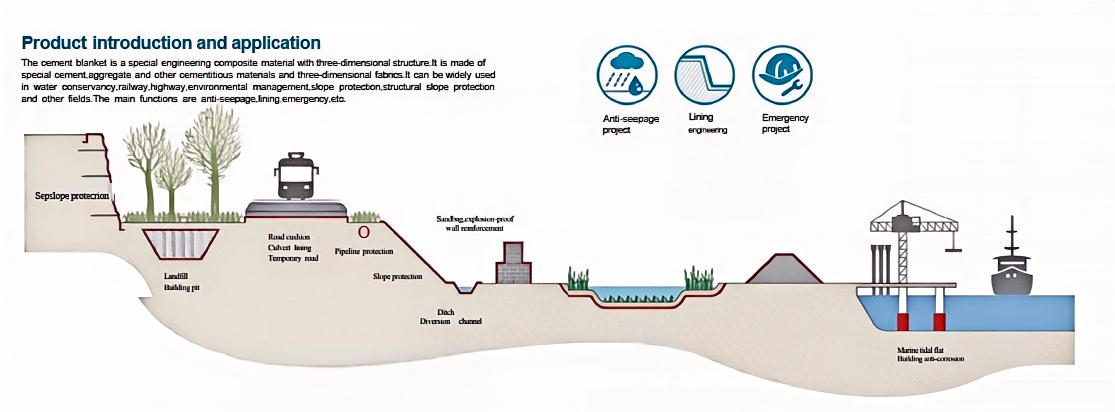

Structural strengthening is a indispensable want for getting older buildings, broken infrastructure, and repurposed structures—and concrete impregnated cloth has emerged as a game-changing solution. Unlike regular concrete, which is heavy and rigid, concrete impregnated material affords flexibility at some point of set up and strong electricity as soon as activated, making it perfect for reinforcing numerous structures. Below are real-world case research that spotlight how concrete fabric cloth and concrete impregnated material have solved frequent structural challenges, handing over durable, reasonable results.

Case Study 1: Strengthening a Historic Brick Wall in a Residential Property

Challenge

A 1920s-era residential domestic in a suburban vicinity confronted a predominant issue: its exterior brick wall, a key structural element, had developed cracks due to soil agreement and a long time of weathering. The property owner desired to keep the wall’s ancient look whilst making sure it may want to stand up to future stress—traditional concrete repairs would have been too bulky, risked detrimental the brick, and disrupted the home’s aesthetic.

Solution: Concrete Impregnated Fabric Application

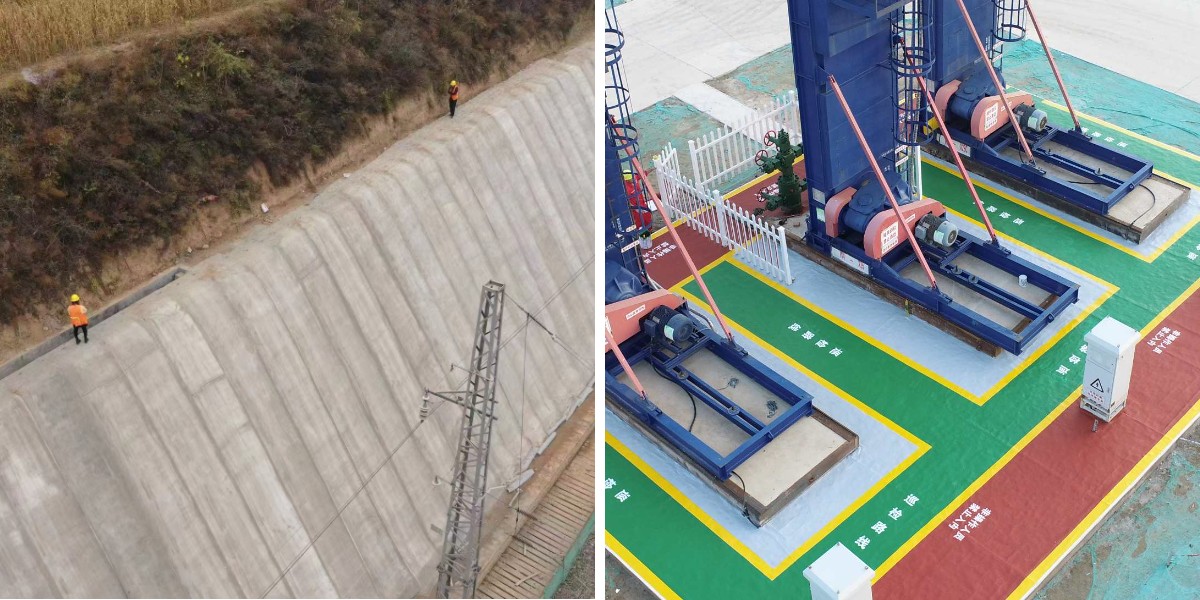

The challenge group selected concrete impregnated cloth for its low-profile set up and compatibility with historical structures. First, they cleaned the brick wall to take away particles and unfastened mortar, making sure the material would adhere properly. Next, they reduce strips of concrete fabric cloth to healthy the peak and size of the wall’s broken sections, leaving a small overlap for seamless bonding.

The cloth was once draped over the cracked areas, then misted with water to spark off the concrete infusion. To preserve the cloth in location whilst hardening, light-weight clamps have been used alongside the edges—these had been eliminated as soon as the fabric set (after forty eight hours). The concrete impregnated material conformed to the brick’s texture, mixing with the wall’s floor except altering its historical look.

Outcome

Six months later, the wall confirmed no signs and symptoms of extra cracking. The concrete impregnated cloth had bolstered the brick structure, distributing weight evenly throughout the wall and stopping similarly agreement damage. The property owner averted steeply-priced wall replacement, and the property’s ancient price used to be preserved—all whilst the usage of a answer that required minimal disruption to day by day life.

Case Study 2: Reinforcing a Commercial Warehouse’s Load-Bearing Beam

Challenge

A mid-sized business warehouse wanted to improve its load-bearing beam to guide heavier inventory. The present beam, made of wood, had begun to sag beneath accelerated weight, posing a security risk. Traditional options like including metal plates would have required huge construction, shutting down components of the warehouse for weeks—a foremost economic burden for the business.

Solution: Concrete Cloth Building Reinforcement

To limit downtime and cost, the group opted for concrete fabric constructing techniques. First, they measured the beam’s dimensions and reduce concrete material cloth into a sleeve that suit snugly round the wood. The material used to be wrapped round the beam, with overlaps pressed firmly collectively to make certain a tight seal.

Before activating the fabric, transient helps have been positioned underneath the beam to relieve strain throughout the hardening process. The concrete fabric cloth was once then sprayed with water, and the group monitored its set time (adjusted barely for the warehouse’s indoor temperature). Once hardened, the cloth shaped a rigid, shielding layer round the wood, efficiently growing the beam’s load-bearing capacity.

Outcome

The warehouse used to be solely closed for two days—one for set up and one for the material to set. Post-installation assessments tested the beam ought to now aid 30% extra weight than before. The concrete fabric constructing answer was once 40% less expensive than metal plate reinforcement, and the beam has maintained its energy over a yr of heavy use, with no symptoms of sagging or wear.

Case Study 3: Repairing a Rural Bridge’s Concrete Abutment

Challenge

A small rural bridge’s concrete abutment (the shape that connects the bridge to the shore) had eroded due to regular publicity to river water and freeze-thaw cycles. The erosion had weakened the abutment, making the bridge dangerous for automobile traffic. Replacing the complete abutment would have been costly and time-consuming, and it would have reduce off get right of entry to to close by farms for weeks.

Solution: Concrete Impregnated Fabric for Erosion Resistance

The assignment crew chosen concrete impregnated material for its sturdiness in moist environments and convenient utility in hard-to-reach areas. They first cleared the eroded part of the abutment, disposing of free concrete and debris. Then, they reduce giant sheets of concrete fabric cloth to cowl the broken area, extending the material barely past the erosion to create a tightly closed base.

The cloth used to be connected to the abutment the use of anchors (to forestall transferring in water) and activated with water. To make sure the material bonded with the current concrete, the group gently scored the abutment’s floor earlier than installation—this helped the moist concrete in the material adhere better. The fabric’s permeability allowed extra water to drain, stopping pooling that should extend hardening.

Outcome

The bridge used to be reopened to site visitors in three days. The concrete impregnated cloth fashioned a waterproof, erosion-resistant layer over the abutment, defending it from future water damage. A 12 months later, inspections confirmed no new erosion, and the abutment’s structural integrity had been completely restored. Local farmers praised the answer for minimizing disruption to their day by day operations.

Key Takeaways from the Case Studies

These profitable initiatives spotlight why concrete impregnated fabric, concrete material fabric, and concrete fabric constructing methods are turning into go-to selections for structural strengthening:

Versatility: The cloth adapts to distinctive structures—from ancient brick partitions to warehouse beams—without compromising on energy or aesthetics.

Speed: Installations are a ways quicker than common repairs, lowering downtime for homes, businesses, and public infrastructure.

Cost-Effectiveness: Concrete impregnated cloth eliminates the want for heavy gear or high priced substances (like steel), reducing venture costs.

Durability: Once hardened, the cloth resists weathering, erosion, and wear, making sure long-term structural stability.

Conclusion

Concrete impregnated cloth is remodeling structural strengthening by way of combining flexibility, strength, and ease of use. The case research above show its capacity to remedy special challenges—preserving ancient structures, minimizing enterprise downtime, and restoring rural infrastructure—all whilst turning in outcomes that stand the check of time. Whether you’re working on a residential repair, industrial upgrade, or public infrastructure project, concrete fabric material and concrete fabric constructing strategies provide a reliable, inexpensive choice to usual strengthening methods. For all and sundry searching for to improve buildings besides the problem of cumbersome substances or prolonged construction, concrete impregnated cloth is a answer really worth considering.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province