What to Look for When Buying Cement Blanket: Quality, Durability & Manufacturer Certifications

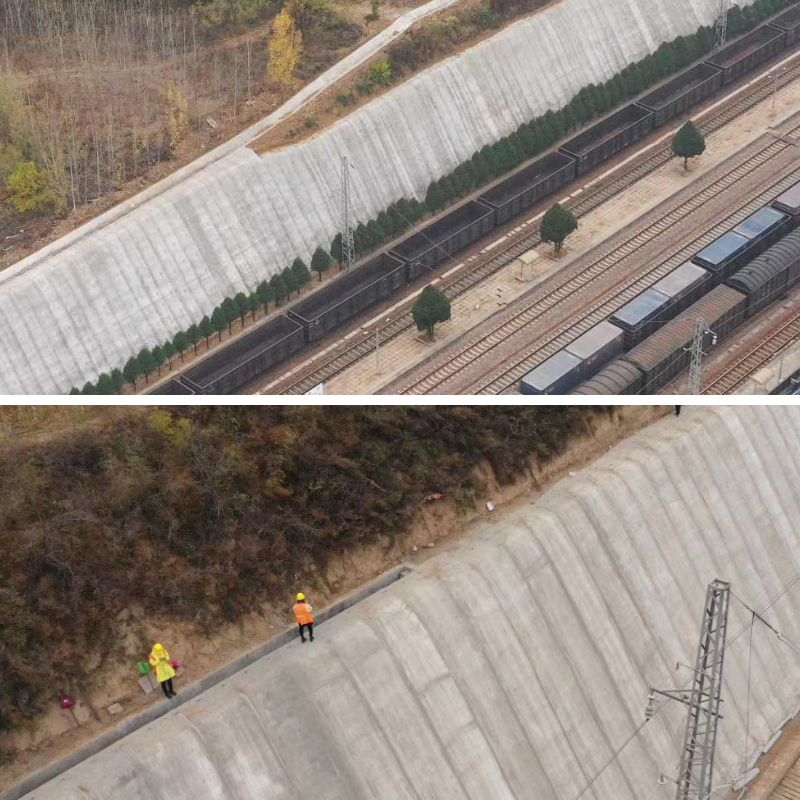

Cement blanket, additionally regarded as cement impregnated fabric, is a modern building fabric that combines the flexibility of cloth with the energy of concrete. Widely used in erosion control, slope stabilization, and fast infrastructure repairs, this cloth affords unmatched comfort and efficiency. However, now not all cement blankets are created equal—quality editions can have an effect on performance, lifespan, and mission safety. This information breaks down the key elements to reflect onconsideration on when buying cement blanket, focusing on satisfactory indicators, sturdiness features, and producer certifications to assist you make an knowledgeable decision.

1. Quality Indicators: Assessing Cement Blanket Core Performance

The great of a cement blanket at once determines its structural integrity and functionality. From uncooked fabric composition to manufacturing precision, countless key elements outline a super product—especially for purposes like concrete blankets for erosion control, the place reliability is non-negotiable.

1.1 Fabric Base and Cement Impregnation Quality

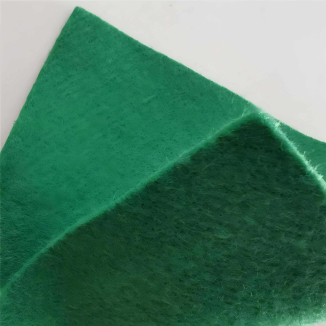

The cloth core of a cement blanket is the basis of its performance. High-quality picks use multi-layered, high-tensile artificial fibers (typically polypropylene or polyester) that withstand tearing, stretching, and chemical degradation. The material ought to have a tight weave or non-woven shape to make sure uniform cement distribution and forestall fiber separation when hydrated.

Cement impregnation is equally critical. Premium cement impregnated cloth makes use of a high-grade Portland cement or blended cement mix, evenly saturated into the cloth fibers. Avoid merchandise with uneven impregnation—visible dry spots or clumps point out terrible manufacturing and will lead to weak, inconsistent concrete formation. Additionally, the cement combine must consist of components (e.g., accelerators, retarders) tailor-made to the supposed application: accelerators for rapid-setting needs, and retarders for tasks requiring prolonged working time.

1.2 Thickness, Weight, and Coverage Capacity

Cement blanket thickness and weight correlate immediately with its load-bearing ability and erosion manage effectiveness. Standard selections vary from 10mm to 25mm in thickness, with weights between 3kg/m² and 15kg/m² (dry). For concrete blankets for erosion manipulate on steep slopes or high-flow areas, choose for thicker, heavier versions (15mm+ thickness, 10kg/m²+ weight) to face up to hydraulic stress and soil movement.

Coverage ability is some other key exceptional metric. High-quality cement blanket keeps steady thickness throughout its whole surface, making sure uniform concrete energy post-hydration. Avoid merchandise with variable thickness, as they will end result in vulnerable factors that are inclined to cracking or failure. Always confirm the manufacturer’s mentioned insurance fee (e.g., m² per roll) to keep away from task delays and fee overruns.

1.3 Hydration and Setting Performance

A fantastic cement blanket must hydrate shortly and uniformly when exposed to water, forming a dense, long lasting concrete layer. Test the product’s placing time—premium picks usually gain preliminary set in 2-4 hours and closing set in 24-48 hours, balancing workability with fast electricity gain. Avoid cement impregnated cloth that units too rapidly (limiting set up flexibility) or too slowly (increasing vulnerability to climate damage).

Post-hydration energy is additionally critical. Look for merchandise that gain a compressive electricity of at least 20 MPa after 7 days and 30 MPa after 28 days—this ensures adequate sturdiness for long-term applications. For concrete blankets for erosion control, ask the producer for power check reviews to affirm overall performance underneath real-world conditions.

2. Durability Features: Ensuring Long-Term Performance

Cement blanket is regularly used in harsh environments—from wet, corrosive soils to uncovered out of doors settings. To maximize lifespan, prioritize merchandise with sturdiness elements that face up to environmental stressors, chemical damage, and bodily wear.

2.1 Resistance to Environmental Stressors

Outdoor purposes demand cement blanket that withstands UV radiation, temperature fluctuations, and moisture. High-quality merchandise consist of UV stabilizers in the material and cement combine to forestall degradation from extended daylight exposure—critical for uncovered slopes or riverbanks the place concrete blankets for erosion manage are left uncoated.

Temperature resistance is additionally essential. The fabric have to function in excessive conditions, from -20°C to +60°C, barring cracking or crumbling. For freeze-thaw-prone areas, pick cement impregnated material with air-entraining additives, which create tiny air bubbles to relieve stress from freezing water and forestall structural damage.

2.2 Chemical and Biological Resistance

In industrial or agricultural settings, cement blanket can also be uncovered to chemical substances (e.g., fertilizers, industrial effluent) or organic increase (e.g., mold, algae). Premium merchandise withstand chemical corrosion, preserving energy when in contact with slight acids, alkalis, and natural compounds. For tasks close to agricultural land or industrial sites, affirm the product’s chemical resistance ranking with the manufacturer.

Biological resistance is equally necessary for concrete blankets for erosion manage in moist environments. Look for cement impregnated cloth handled with anti-fungal or anti-algal components to forestall organic growth, which can weaken the concrete layer and compromise erosion manage effectiveness.

2.3 Abrasion and Impact Resistance

Cement blanket used in high-traffic areas or close to flowing water should withstand abrasion and impact. High-quality selections have a strengthened cloth core and dense concrete matrix that withstands scouring from waterborne particles or bodily contact (e.g., development equipment). For riverbank stabilization or channel lining, pick out merchandise with a textured floor or extra put on layer to decorate abrasion resistance.

Impact resistance is additionally imperative for purposes inclined to falling particles or heavy loads. Test the product’s potential to stand up to blunt force—premium cement blanket need to no longer crack or chip easily, making sure structural integrity even beneath sudden stress.

3. Manufacturer Certifications: Verifying Reliability and Compliance

Manufacturer certifications are a depended on indicator of product nice and compliance with enterprise standards. When shopping for cement blanket, prioritize manufacturers with identified certifications, as they reveal rigorous checking out and adherence to security and overall performance guidelines.

3.1 International and Industry Standards Certifications

Look for cement blanket licensed to worldwide requirements such as ISO 9001 (quality administration system) and ISO 14001 (environmental administration system)—these make certain steady manufacturing techniques and minimal environmental impact. For concrete blankets for erosion control, take a look at for compliance with civil engineering requirements like ASTM D6270 (standard specification for geotextile-reinforced concrete mats) or EN 13706 (geosynthetics for civil engineering applications).

Regional certifications are additionally important. In North America, merchandise need to meet AASHTO (American Association of State Highway and Transportation Officials) requirements for dual carriageway and infrastructure projects. In Europe, CE marking suggests compliance with EU safety, health, and environmental requirements. Avoid merchandise besides third-party certification, as they lack impartial verification of performance.

3.2 Quality Control and Test Reports

Reputable producers furnish particular check reviews for their cement blanket, together with outcomes for compressive strength, putting time, cloth tensile strength, and environmental resistance. Ask for batch-specific check reviews to make certain the product you acquire fits the licensed specifications. Additionally, inquire about the manufacturer’s great manage processes—premium manufacturers habits in-line checking out all through manufacturing to discover defects and make sure consistency.

For cement impregnated cloth used in indispensable functions (e.g., flood control, structural repairs), request certification from unbiased checking out laboratories (e.g., UL, TÜV) to verify overall performance claims. This greater verification minimizes the hazard of the use of substandard merchandise that should lead to mission failure.

3.3 Manufacturer Reputation and After-Sales Support

A manufacturer’s recognition is a reflection of product quality. Research patron reviews, case studies, and venture portfolios to investigate the brand’s song record—look for businesses with trip in presenting cement blanket for comparable functions (e.g., concrete blankets for erosion manage in coastal areas or mountainous regions).

After-sales assist is additionally critical. Choose producers that provide technical guidance, set up training, and guarantee coverage. A complete guarantee (typically 1-5 years) suggests self belief in product sturdiness and affords peace of idea in case of untimely failure. Avoid manufacturers with restricted or no after-sales support, as they may additionally no longer stand in the back of their products.

Final Checklist for Buying Cement Blanket

When buying cement blanket, use this guidelines to make sure you choose a high-quality, long lasting product: Verify the cloth core and cement impregnation quality; Confirm thickness, weight, and post-hydration strength; Assess resistance to UV, temperature, chemicals, and abrasion; Check for global and enterprise certifications; Request batch-specific check reports; Evaluate producer popularity and after-sales support.

Whether for concrete blankets for erosion control, slope stabilization, or speedy repairs, investing in a best cement blanket with desirable certifications ensures long-term performance, reduces renovation costs, and minimizes task risks. By prioritizing quality, durability, and producer credibility, you can pick a product that meets your project’s special wishes and stands the check of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province