Reducing Carbon Footprint with Geotextile Tubes in Construction

Introduction: The Construction Industry's Sustainability Challenge

The worldwide improvement vicinity faces big stress to restriction its environmental impact. As a huge contributor to carbon emissions and beneficial aid consumption, the company urgently wishes innovative, practical solutions. Among the most promising tendencies is the strategic use of geotextile tube technology. These engineered containers, moreover often referred to as Geotube devices or Dewatering Bags, supply a multifaceted method to lowering carbon footprints in the course of a variety undertaking phases. This article explores how integrating these constructions into constructing workflows now no longer completely solves traditional engineering challenges on the other hand moreover drives large sustainability gains, aligning with inexperienced developing goals and environmental regulations.

What Are Geotextile Tubes and How Do They Function?

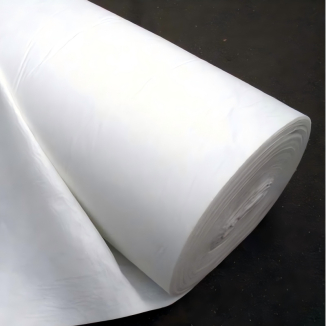

A geotextile tube is a large, permeable container fabricated from high-strength woven or composite geotextile materials. Designed for sturdiness and environmental resilience, these tubes are deployed by using the use of filling them with slurry—a aggregate of water and secure supplies like dredged sediment, industrial sludge, or improvement net website runoff. The core technique entails dewatering: water passively drains through the fabric's tiny pores, while the sturdy particles are retained inside. Over time, this yields a substantially reduced extent of contained, impenetrable solids.

Often used synonymously, Dewatering Bags are generally smaller-scale variants of this technology, best for managing sediment control or smaller waste streams. The massive Geotube devices take care of giant volumes, serving in predominant functions like land reclamation, shoreline protection, and bulk dewatering. This surroundings pleasant separation approach is the cornerstone of their environmental benefit, casting off the favor for energy-intensive mechanical dewatering tools and lowering associated emissions.

Key Areas for Carbon Reduction Using Geotube Technology

1. Sludge and Sediment Management with Lower Emissions

Traditional methods for dealing with dredged materials or improvement sludge often incorporate transportation of high-water-content waste to far-off disposal sites. This approach requires fleets of trucks, major to widespread gas consumption and greenhouse fuel emissions. By the usage of geotextile tubes straight away on-site or at a shut via staging area, the volume of cloth for transport is notably reduced. A single Geotube dewatering project can minimize hauling requirements via 70% or more, without delay slashing carbon emissions from logistics. The Dewatering Bags play a same function for smaller, ongoing internet site runoff, stopping sediment-laden water from leaving the net web page and minimizing cleanup operations.

2. Minimizing the Use of Carbon-Intensive Traditional Materials

In coastal and civil engineering, normal constructions like rock revetments or concrete seawalls have immoderate embodied carbon due to quarrying, processing, and transportation. Geotextile tubes supply a manageable preference for erosion control and retaining structures. When stuffed with close by dredged sand or on-site suitable sediments, they come to be stable, long lasting barriers. This workout repurposes waste material, avoids the carbon fee of importing rock or manufacturing concrete, and closes the cloth loop on projects. The carbon saved in material sourcing and manufacturing is a vital advantage of the Geotube approach.

3. On-Site Dewatering and Waste Consolidation

Construction web sites regularly generate moist waste, from tunnel boring muck to excavation runoff. Managing this with usual strategies frequently consists of energy-heavy mechanical presses or centrifuges. The passive dewatering done with geotextile tubes requires minimal energy—only for the preliminary pumping of slurry. This huge cut price in device electrical energy consumption right now lowers the project's operational carbon footprint. Furthermore, the contained, dewatered solids are greater regular for ultimate disposal or truely beneficial reuse, stopping secondary environmental impacts.

The Lifecycle Advantage: Durability and Reusability

The sustainability of Geotube buildings extends past right away dewatering benefits. High-quality geotextile tube elements are engineered for long-term usual overall performance in harsh environments. When used for everlasting or semi-permanent structures, their sturdiness reduces the prefer for widespread replacements or repairs related with increased normal methods. This sturdiness interprets to reduce long-term material consumption and a whole lot much less disruptive constructing activity over time.

In some applications, geotextile tubes can be designed for transient use, then cleaned and redeployed on each different task phase or a one-of-a-kind internet web page altogether. This reusability in a similar fashion amplifies their environmental credentials by spreading the preliminary embodied carbon of manufacturing over greater than one uses, a principle central to the spherical economy. Even single-use Dewatering Bags for sediment manipulate are often recyclable, diverting fabric from landfills.

Practical Applications in Sustainable Construction

Land Reclamation and Foundation Support: Using Geotube containers stuffed with dredged material to create new landforms avoids the carbon-intensive exercising of importing hundreds and heaps of loads of fill fabric by using way of truck or barge.

Erosion Control and Shoreline Protection: Installing geotextile tube constructions alongside riverbanks or coastlines stabilizes soil with nearby materials, defending property at the same time as bettering habitats barring the carbon footprint of quarrying and placing rock.

Contaminated Sediment Remediation: Geotube devices furnish a safe, contained approach for dewatering and solidifying contaminated sludge on-site, stopping top sized disturbance and decreasing the risk and transport emissions associated with off-site treatment.

Construction Site Water Management: Utilizing Dewatering Bags at stormwater outfalls or sediment ponds ensures compliance with environmental regulations, protects close by waterways, and simplifies internet site administration with a low-carbon solution.

Conclusion: Building a Greener Future with Smart Technology

Adopting geotextile tube technological expertise is a clear strategic bypass for improvement companies committed to sustainability and carbon reduction. The benefits are compelling: significantly diminished transport emissions, minimize consumption of virgin materials, decreased electricity use for dewatering, and advertising of spherical economic machine practices by using reuse and recycling. From massive Geotube coastal defenses to fundamental Dewatering Bags on a residential site, this versatile science gives a practical, high quality path to meeting environmental targets.

As the agency evolves, integrating picks like geotextile tubes into famous exercising will be necessary for setting up the infrastructure of day after nowadays barring compromising the health of our planet. By prioritizing enhancements that cope with every engineering and environmental challenges, we can gather a more resilient and sustainable world.

Ready to find out how geotextile dewatering choices can minimize the carbon footprint of your subsequent project? Contact a professional these days to discuss about your unique utility and locate out the viable environmental and economic savings.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province