Leak Detection Methods for HDPE Containment Systems

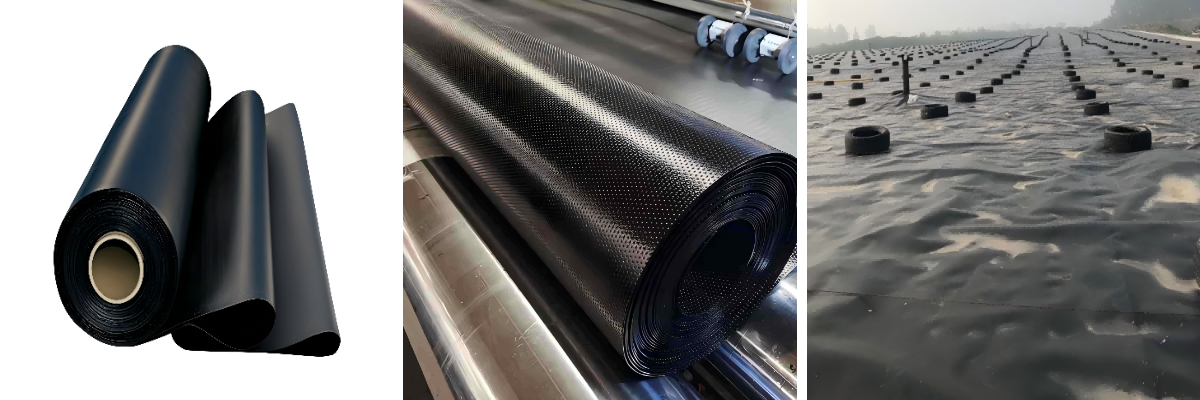

HDPE containment systems—relied on for landfills, wastewater treatment, and chemical storage—depend on the integrity of hdpe geomembrane to forestall leaks and defend the environment. As a durable, bendy impermeable geomembrane, HDPE affords amazing barrier performance, however even minor defects can lead to expensive contamination, regulatory penalties, or machine failure. Implementing fine leak detection strategies is quintessential to preserving the reliability of these systems, whether or not you’re managing a new set up or an growing older facility. This information breaks down the most depended on leak detection methods for HDPE containment systems, explains when to use every method, and highlights how choosing best substances (and perception elements like harga hdpe geomembrane) affects long-term leak resistance.

Why Leak Detection Is Non-Negotiable for HDPE Containment

HDPE geomembrane is chosen for containment structures due to the fact of its chemical resistance, UV stability, and capacity to shape a seamless barrier. However, leaks can happen due to set up mistakes (e.g., bad welding), cloth fatigue, or exterior injury (e.g., root penetration or development activity). Even a small pinhole can launch contaminants into soil or groundwater, triggering environmental damage and felony consequences. For tasks the place harga hdpe geomembrane is a consideration, slicing corners on leak detection can lead to a ways greater expenses down the line—repairs, fines, and remediation frequently outweigh the price of proactive monitoring. A strong leak detection software ensures your impermeable geomembrane performs as designed, defending each your funding and the surrounding ecosystem.

Pre-Installation Leak Prevention: Laying the Groundwork

Before putting in hdpe geomembrane, proactive steps minimize the hazard of leaks and simplify future detection. This segment is specifically vital for balancing fine and harga hdpe geomembrane—investing in training avoids luxurious fixes later.

Material Selection and Inspection

Choose hdpe geomembrane that meets enterprise requirements (e.g., ASTM G173 for UV resistance) and fits your project’s wishes (thickness, chemical compatibility). Even if harga hdpe geomembrane is a priority, keep away from low-quality substances with hidden defects (e.g., skinny spots or manufacturing flaws). Inspect rolls upon transport for tears, punctures, or inconsistent thickness—reject any fabric that fails fantastic checks.

Base Preparation and Installation Best Practices

A smooth, debris-free base prevents punctures in the impermeable geomembrane. Clear the website of rocks, roots, and sharp objects, compact the soil, and lay a geotextile underlay if needed. During installation, make certain seams are welded through licensed technicians the use of warmth fusion or extrusion welding—test each seam with air stress or vacuum techniques earlier than covering. Proper set up reduces the possibility of leaks, making post-installation detection extra effective.

Post-Installation Leak Detection Methods

Once hdpe geomembrane is installed, normal checking out and monitoring are essential. Below are the most dependable methods, tailor-made to specific venture scales and containment types.

1. Electrical Leak Location (ELL) Testing

The gold popular for detecting pinholes and small defects in hdpe geomembrane, ELL checking out makes use of electrical conductivity to perceive breaches. It works satisfactory on smooth, non-conductive surfaces (e.g., HDPE over a conductive base like moist soil or a conductive liner).

How It Works

A low-voltage cutting-edge is utilized throughout the impermeable geomembrane—one electrode is positioned on the geomembrane surface, and any other is buried in the conductive base below. If a leak exists, cutting-edge flows via the breach, growing a detectable signal. Technicians use a probe to map the sign and pinpoint the leak’s location.

Best For

New installations (pre-filling), landfill liners, and large-scale containment systems. ELL trying out is fast, accurate, and can cowl giant areas efficiently—critical for tasks the place harga hdpe geomembrane is paired with tight timelines.

2. Vacuum Box Testing

A portable, non-destructive technique for trying out seams and small areas of hdpe geomembrane, vacuum container checking out is perfect for spot-checking welds or suspect areas.

How It Works

A sealed container (with a obvious top) is positioned over the vicinity to be tested, and a vacuum is applied. If a leak exists, air is drawn thru the breach, inflicting a cleaning soap answer (applied to the geomembrane) to bubble. Technicians mark the effervescent location for repair.

Best For

Testing man or woman seams, small containment structures (e.g., storage tanks), or post-repair verification. It’s low in cost and requires minimal equipment, making it available for tasks with price range constraints (even these conscious of harga hdpe geomembrane).

3. Hydrostatic Testing

For liquid containment structures (e.g., ponds, tanks), hydrostatic trying out tests for leaks by way of filling the gadget with water and monitoring for quantity loss or strain drops.

How It Works

Fill the containment device with water to the plan level, then display the water stage over a set length (typically 24–48 hours). A substantial drop shows a leak in the impermeable geomembrane. For massive systems, strain sensors can music adjustments and slim down leak locations.

Best For

Water storage facilities, lagoons, and small to medium-sized containment ponds. Note that hydrostatic trying out is much less particular for pinpointing leaks than ELL however is positive for confirming general machine integrity.

4. Monitoring Wells and Geophysical Surveys

For long-term leak detection in buried or protected containment structures (e.g., landfills), monitoring wells and geophysical surveys supply ongoing insights into possible breaches.

How It Works

Monitoring Wells: Install wells round the containment gadget to pattern groundwater for contaminants. Elevated degrees of chemical substances (e.g., leachate from landfills) sign a leak in the hdpe geomembrane.

Geophysical Surveys: Techniques like electrical resistivity or ground-penetrating radar (GPR) map subsurface changes, such as moisture buildup or contaminant plumes, which point out leaks.

Best For

Aging containment systems, landfills, or web sites the place normal bodily get admission to to the impermeable geomembrane is limited. While greater highly-priced than spot-testing methods, they furnish non-stop protection—worth the funding for high-risk sites, even when harga hdpe geomembrane used to be a key consideration throughout installation.

Integrating Leak Detection with Material Quality

The effectiveness of leak detection is intently tied to the satisfactory of hdpe geomembrane used. Low-cost substances (with decrease harga hdpe geomembrane) can also have weaker weldability or thinner sections, growing leak danger and making detection harder. Investing in awesome HDPE (e.g., virgin resin, constant thickness) reduces the variety of defects, making leak detection quicker and greater reliable. Additionally, pairing first-rate geomembrane with suited set up (e.g., licensed welders) minimizes the want for commonplace repairs, balancing upfront charges with long-term savings.

Conclusion: A Proactive Approach to HDPE Containment Integrity

Leak detection is no longer a one-time challenge however a non-stop technique that begins with cloth decision and extends via the existence of the containment system. By combining sturdy pre-installation practices, focused checking out techniques (like ELL or vacuum container testing), and ongoing monitoring, you make certain your hdpe geomembrane stays a dependable impermeable geomembrane. Even when harga hdpe geomembrane is a factor, prioritizing leak detection saves money, protects the environment, and keeps compliance with regulations. For any HDPE containment project, a proactive center of attention on leak prevention and detection is the key to long-term success.

Contact Us

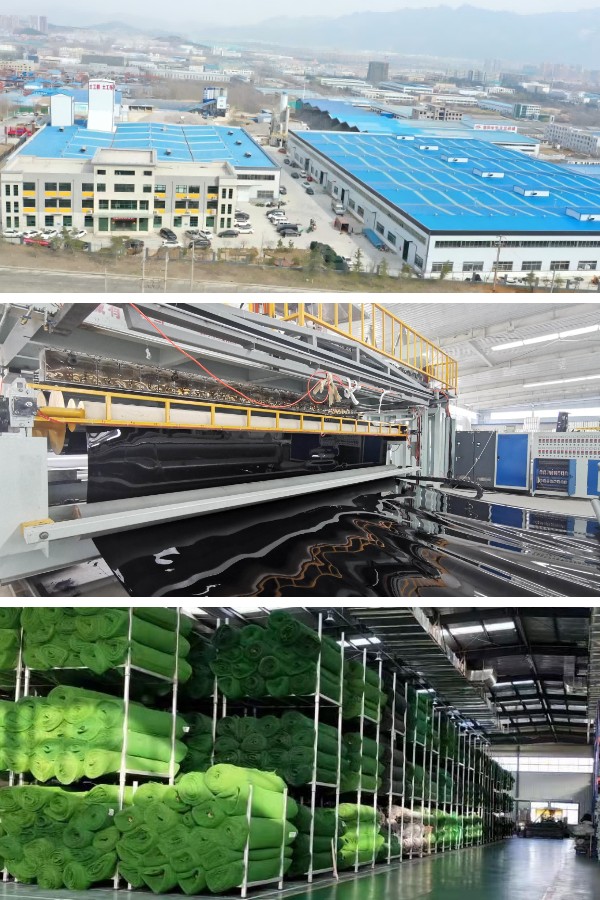

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province