Key Factors to Evaluate When Buying HDPE Geomembrane: Avoid Low-Quality Products

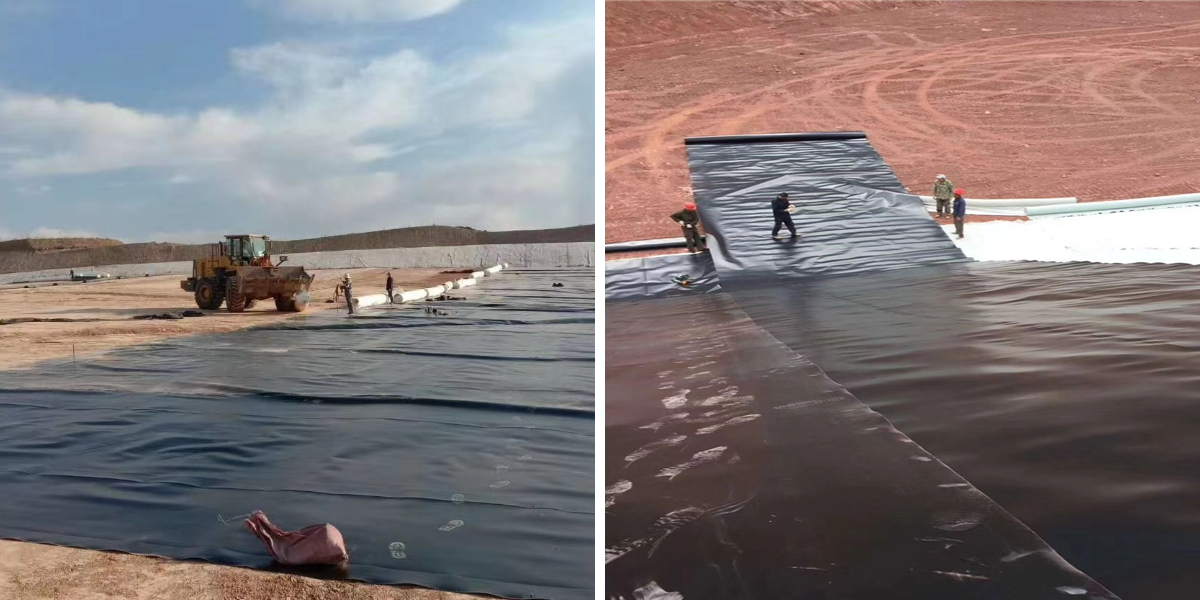

HDPE geomembrane, a long lasting artificial liner made from high-density polyethylene, is a indispensable thing in tasks like landfill containment, water reservoirs, agricultural irrigation, and mining tailings management. Its foremost role—preventing seepage and environmental contamination—depends completely on its quality. Unfortunately, the market is saturated with low-quality geomembrane merchandise that use substandard substances or ignore manufacturing checks. These merchandise fail prematurely, inflicting luxurious leaks, mission delays, and even environmental penalties. To guard your investment, focal point on these 4 non-negotiable elements when choosing HDPE geomembrane.

1. Material Quality & Core Performance Indicators

The basis of a dependable HDPE geomembrane lies in its uncooked substances and inherent performance. Low-quality geomembrane frequently cuts corners here—using recycled plastic blends as an alternative of pure virgin HDPE resin, or omitting components that raise durability. To keep away from this, affirm these key metrics:

Thickness Consistency

HDPE geomembrane thickness varies through challenge (e.g., 1.0mm for small ponds, 1.5mm+ for landfills), however consistency throughout the roll is non-negotiable, as skinny spots in low-quality liners turn out to be instantaneous seepage risks; to check, use a precision caliper to measure thickness at 8–10 random points, and per enterprise norms like ASTM D751, the deviation must now not exceed ±5% of the labeled thickness, whilst rolls with seen skinny patches or an inconsistent sense when touched are crimson flags of shoddy production.

Virgin HDPE Resin Content

Pure virgin HDPE resin ensures the geomembrane’s strength, flexibility, and longevity, so you have to ask suppliers to verify they use a hundred percent virgin HDPE resin and request a fabric certificates proving the resin’s beginning and purity—low-quality products, by way of contrast, combine recycled plastic (often from unknown sources) to decrease costs, which weakens the liner and can decrease tensile electricity by way of 25–40%, making the HDPE geomembrane susceptible to tearing at some point of installation.

Chemical & UV Resistance

HDPE geomembrane frequently faces harsh conditions, such as landfill leachate, agricultural fertilizers, or extended solar exposure, and low-quality liners lack anti-chemical and UV stabilizers that lead to speedy degradation; for this reason, habits project-specific checks: make sure landfill liners withstand natural acids and heavy metals, and confirm UV resistance (per ASTM G154) for outside reservoirs to forestall the geomembrane from turning into brittle over time.

2. Manufacturer Credentials & Production Transparency

A reliable producer is as essential as the HDPE geomembrane itself. Many low-quality merchandise come from uncertified workshops that lack standardized manufacturing strains or fantastic manipulate (QC) systems. Vet producers the use of these criteria:

Industry Certifications

Legitimate HDPE geomembrane producers preserve non-negotiable certifications that validate their strategies and products, consisting of ISO 9001 (which ensures constant manufacturing first-rate and QC protocols), GRI-GM (a international benchmark for geomembrane overall performance protecting cloth protection and durability), and nearby compliance certifications (e.g., CE for the EU, GB/T 17643 for China) to meet assignment codes—you have to keep away from producers that solely furnish “self-issued” certificates, as these are frequently faux and disguise low-quality geomembrane production.

Production Process Transparency

High-quality HDPE geomembrane is made by means of extrusion molding, the place virgin resin is melted, filtered for impurities, extruded into sheets, and cooled underneath managed temperatures, however low-quality producers bypass filtering or rush cooling to keep time; to verify this, ask producers three key questions: whether or not they share real-time manufacturing pictures or permit manufacturing unit visits, what QC steps manifest for the duration of manufacturing (e.g., on-line thickness monitoring, impurity checks), and how they deal with faulty rolls—reliable producers will reply openly, whilst indistinct responses point out they’re hiding manufacturing shortcuts.

3. Third-Party Testing & Traceability

Suppliers frequently declare their HDPE geomembrane meets standards—but besides unbiased verification, these are simply words. Low-quality geomembrane retailers often falsify check reviews to mimic best products. Always demand third-party validation:

Must-Perform Third-Party Tests

Focus on three key assessments to affirm HDPE geomembrane quality: seam electricity checks (per ASTM D1647, seams welded all through set up need to have energy ≥80% of the geomembrane’s tensile strength, as vulnerable seams in low-quality liners reason leaks), Environmental Stress Cracking Resistance (ESCR) exams (per ASTM D1693, ESCR values must make certain a 10–20 12 months lifespan, in contrast to low-quality merchandise that fail in 2–3 years), and hydrostatic resistance assessments (verify the geomembrane can block water via preserving 1.5x the project’s most water strain barring seepage, fundamental for reservoir applications).

Product Traceability

Every roll of high-quality HDPE geomembrane has a special batch quantity that hyperlinks to key information: the uncooked cloth supply (resin origin), manufacturing files (date, computing device used), and third-party check reports—you need to request this batch wide variety and cross-check it with the manufacturer’s database and check records; if a dealer can't grant a traceable batch number, the geomembrane is probably low-quality or counterfeit, as official producers prioritize full traceability.

4. Post-Sales Support & Warranty Coverage

HDPE geomembrane requires suited set up and long-term protection to function well, and low-quality suppliers frequently disappear after sale, leaving you to manage problems alone. Evaluate post-sales abilities to keep away from this risk:

On-Site Installation Guidance

Improper set up (e.g., improper welding temperature, bad seam alignment) can break even super HDPE geomembrane, so legitimate suppliers provide precious support: they ship on-site engineers to information your group or furnish licensed installers for the work, and they share detailed, project-specific set up manuals (not commonplace documents) that cowl welding parameters, seam inspection, and restore procedures—low-quality suppliers, by using contrast, solely furnish simple directions or no aid at all, growing the danger of set up errors.

Warranty & Leak Resolution

A sturdy assurance displays a supplier’s self belief in their HDPE geomembrane: exceptional liners come with 5–10 12 months fabric warranties overlaying defects like cracking or brittleness, and some even provide overall performance warranties for seepage issues; low-quality products, however, both have no guarantee or a brief 1–2 yr insurance period, and when leaks occur, these suppliers refuse to aid with repairs—always get assurance phrases in writing and affirm what’s included (e.g., cloth defects, installation-related issues) earlier than purchasing.

Conclusion

Choosing the proper HDPE geomembrane is now not simply a buying decision—it’s a dedication to the safety, durability, and environmental compliance of your project. Low-quality geomembrane might also appear low in cost upfront, however it leads to devastating consequences: highly-priced leaks, venture shutdowns, environmental fines, and wasted investments. By carefully evaluating the 4 core factors—material satisfactory (prioritizing virgin HDPE resin and constant performance), producer credibility (valid certifications and obvious production), third-party validation & traceability (independent exams and batch tracking), and post-sales help (professional set up training and sturdy warranties)—you can do away with the threat of low-quality products. Investing time in these exams ensures your HDPE geomembrane supplies on its promise: long-term seepage protection, decreased renovation costs, and peace of thinking that your venture meets enterprise requirements and environmental goals.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province