Key Components: Understanding the Geotextile and HDPE Layers in a Composite Liner

Introduction to Composite Liner Systems

In current civil and environmental engineering, composite liner structures have grow to be a cornerstone for containment, stabilization, and protection. These engineered structures are designed to function crucial features the place single-layer options fall short. At the coronary heart of an wonderful composite liner are two principal factors working in synergy: a sturdy geotextile layer and a high-density polyethylene (HDPE) geomembrane. This article delves into the roles, benefits, and integration of these materials, focusing on the geotextile for soil stabilization and the impermeable HDPE Composite Geomembrane. Understanding this Composite Geo-membrane gadget is vital for engineers, undertaking managers, and environmental professionals aiming to make certain long-term undertaking integrity.

The Geotextile Layer: Foundation for Stability and Protection

Primary Functions and Material Characteristics

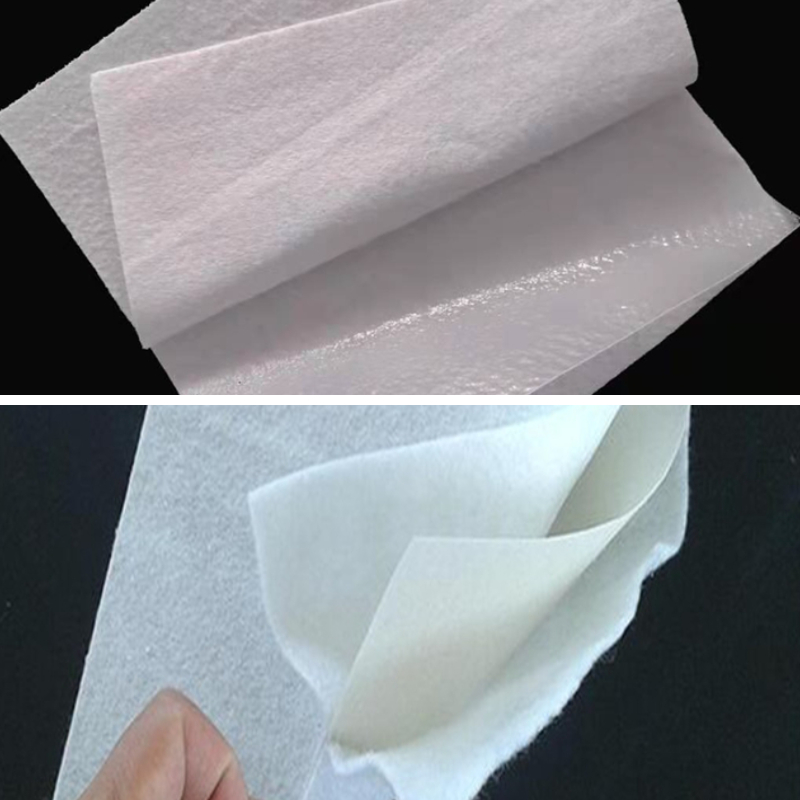

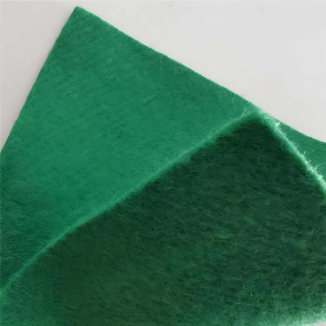

The geotextile layer in a composite gadget is a long way greater than simply a separator. It is a versatile, permeable artificial material engineered to supply fundamental mechanical and hydraulic functions. Its principal position inside a Composite Geo-membrane is to provide geotextile for soil stabilization, reinforcement, and protection. When positioned on unstable or tender subgrades, the geotextile distributes loads, reduces differential settlement, and will increase the normal bearing capability of the soil. This stabilization is integral for growing a uniform, steady working platform for the subsequent layers.

Furthermore, the geotextile acts as a imperative protecting cushion for the subtle HDPE Composite Geomembrane laid above it. By stopping direct contact with sharp aggregates or irregular subsoil, it mitigates the chance of puncture and stress damage. Its permeable nature additionally enables the lateral drainage of any gases or moisture that may additionally accumulate at the interface, stopping stress build-up that ought to compromise the system. This mixture of stabilization, protection, and drainage makes the geotextile an vital first line of protection in any composite liner application.

The HDPE Geomembrane Layer: The Impermeable Barrier

Unmatched Durability and Chemical Resistance

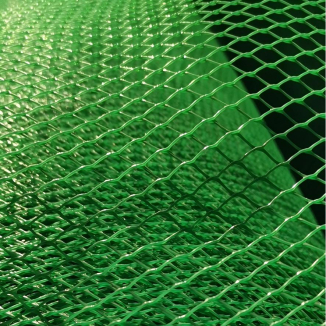

The HDPE Composite Geomembrane is the impermeable coronary heart of the system. Manufactured from high-density polyethylene resin, this geomembrane is famend for its top notch durability, sturdy tensile strength, and first-rate resistance to a broad vary of chemicals, UV radiation, and environmental stress cracking. Its essential feature is to create a continuous, invulnerable barrier that prevents the migration of liquids, vapors, or contaminants. This is essential in functions such as landfill liners, reservoir caps, mining leach pads, and secondary containment.

The effectiveness of the HDPE Composite Geomembrane lies in its very low permeability coefficient. When true manufactured and installed, it varieties a near-absolute seal. Its overall performance is in addition better when built-in with a geotextile, forming a most advantageous Composite Geo-membrane. The textured floor reachable on many HDPE geomembranes will increase interface friction with adjoining soils or geotextiles, improving slope stability. The toughness and reliability of the HDPE layer are what make the whole composite device a depended on answer for long-term containment projects.

Synergistic Performance: How the Layers Work Together

Creating a System Greater Than the Sum of Its Parts

The real engineering excellence of a composite liner is realized in the synergistic interplay between the geotextile and HDPE layers. A standalone HDPE Composite Geomembrane, whilst impermeable, is susceptible to set up injury and subgrade imperfections. A standalone geotextile for soil stabilization can't stop fluid migration. Combined, they structure a high-performance Composite Geo-membrane that addresses each challenges simultaneously.

The geotextile layer prepares and stabilizes the subgrade, developing a smooth, consolidated surface. It then protects the HDPE sheet from puncture for the duration of and after installation. Conversely, the HDPE layer shields the geotextile from doable chemical assault from the contained materials. In drainage scenarios, the geotextile can filter particles whilst permitting water to pass by freely to series drains, with the HDPE layer making sure no downward leakage. This partnership ensures best overall performance underneath mechanical stress, hydraulic pressure, and over prolonged carrier life, supplying self belief in the containment structure's integrity.

Key Considerations for Specification and Installation

Ensuring Optimal Performance of the Composite System

Selecting and putting in a Composite Geo-membrane requires cautious planning. For the geotextile for soil stabilization, key specs consist of tensile strength, puncture resistance, permittivity (for drainage), and weight. The preference relies upon on the subsoil prerequisites and the required stage of safety for the HDPE Composite Geomembrane.

For the HDPE layer, thickness, density, and textured vs. easy floor are vital decisions. Thicker geomembranes provide larger puncture resistance and longevity. All aspects ought to be like minded with the chemical surroundings of the challenge site.

Installation is paramount. The subgrade ought to be appropriate prepared. The geotextile for soil stabilization ought to be laid easily with ample overlap and seaming. The HDPE Composite Geomembrane panels need to be deployed carefully, with seams thermally fused by using licensed welders to create a continuous, monolithic barrier. Every seam ought to be non-destructively examined to make sure integrity. Proper anchorage and cowl are additionally quintessential to whole the system.

Conclusion: The Indispensable Composite Solution

In conclusion, the integration of a committed geotextile for soil stabilization with a strong HDPE Composite Geomembrane creates an engineered answer of unmatched reliability. This Composite Geo-membrane device leverages the strengths of every factor to supply most useful overall performance in stabilization, separation, protection, and, most importantly, impermeable containment. Whether for environmental protection, water conservation, or industrial infrastructure, appreciation these key factors permits for the knowledgeable format and implementation of liner structures that are constructed to last, safeguarding tasks and the surroundings for many years to come. When planning your subsequent containment project, specifying a proper designed composite liner is a necessary step towards attaining long-term success and sustainability.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province