How to Test Cement Blanket Quality: A Buyer’s Checklist for Strength & Cure Time

When it comes to development projects, the fantastic of substances immediately determines the sturdiness and protection of the closing structure. Cement blanket, additionally recognized as cement canvas, has received big reputation in latest years due to its convenience, fast construction, and robust adaptability. However, the nice of cement blanket on the market varies greatly—some merchandise fail to meet energy necessities or have atypical remedy times, main to assignment delays and doable protection hazards. As a buyer, gaining knowledge of scientific fantastic checking out strategies is necessary to keep away from buying inferior products. This article will furnish a exact guidelines overlaying 4 key elements to assist you precisely investigate cement blanket quality.

1. Compressive Strength Testing: The Core Indicator of Cement Blanket Durability

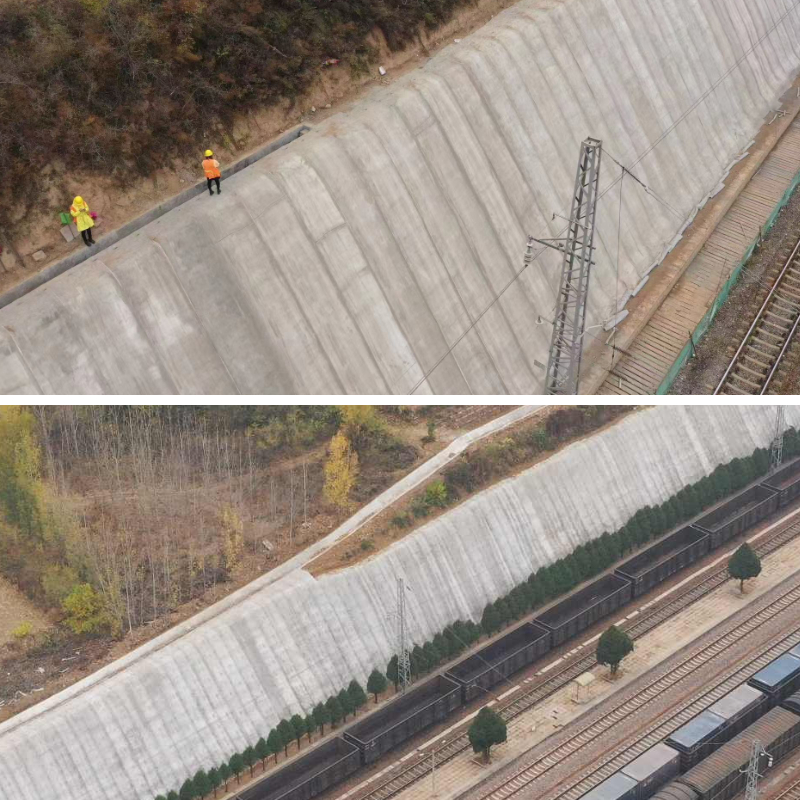

Compressive energy is the most integral index to measure the load-bearing ability of cement blanket, as it without delay relates to whether or not the product can face up to long-term strain in realistic purposes such as slope protection, channel lining, and transient construction. Inferior cement blanket regularly makes use of low-grade cement or inadequate cement content, ensuing in compressive energy a long way under the standard. Here’s how to take a look at and confirm it:

1.1 Follow Standard Testing Procedures

First, gain a consultant pattern from the cement blanket roll. According to the enterprise wellknown ASTM C109/C109M (Standard Test Method for Compressive Strength of Hydraulic Cement Mortars), reduce the pattern into cubes of 50mm×50mm×50mm. Ensure the pattern is free of cracks, bubbles, or uneven fiber distribution. Then, location the pattern in a wellknown curing surroundings (temperature 20±2℃, relative humidity ≥95%) for 28 days—this is the general curing length for cement-based substances to attain secure strength.

After curing, use a conventional checking out laptop to observe strain to the pattern at a uniform velocity (2.4kN/s). Record the most stress when the pattern is crushed, and calculate the compressive energy the usage of the formula: Compressive Strength (MPa) = Maximum Pressure (N) / Cross-sectional Area (mm²). Qualified cement blanket need to have a compressive electricity of at least 20MPa after 28 days of curing; for initiatives with excessive load requirements (such as street base reinforcement), the power must attain 30MPa or more.

1.2 On-Site Rapid Verification Tips

If you don’t have expert trying out tools on-site, you can use a easy technique for preliminary judgment: take a cured cement blanket pattern (cured for at least 7 days) and faucet it with a hammer. High-quality cement blanket will emit a clear, crisp sound, whilst inferior merchandise will make a dull, muffled sound. Additionally, you can attempt scratching the floor with a sharp tool—high-strength cement canvas will only leave moderate scratches, whilst low-quality ones will peel off easily.

2. Cure Time Verification: Ensure Construction Efficiency and Strength Development

Cure time is any other key issue affecting the realistic utility of cement blanket. Too lengthy a therapy time will lengthen the development schedule, whilst too brief a time will end result in inadequate energy development. The preferred therapy time of cement blanket is intently associated to its formulation and environmental conditions, and consumers want to affirm it from each producer claims and on-site tests.

2.1 Confirm Manufacturer’s Cure Time Specifications

When purchasing, ask the producer for a special product specification sheet, focusing on the preliminary set time and closing set time. Generally, exquisite cement blanket has an preliminary set time of 2-4 hours and a closing set time of 6-12 hours beneath widespread prerequisites (20±2℃, relative humidity 60-80%). If the producer claims an excessively quick remedy time (such as closing set in three hours), it may additionally point out immoderate accelerators, which will have an effect on the long-term sturdiness of the cement canvas. Conversely, a remedy time longer than sixteen hours might also imply the cement has expired or the retarder is overused, main to development delays.

2.2 On-Site Cure Time Testing Method

Conduct on-site curing exams with the bought cement blanket. Cut a 30cm×30cm sample, soak it in easy water for 5-10 minutes (consistent with on-site development soaking time), then location it in the authentic building environment. Record the preliminary set time (when the floor no longer sticks to the finger and has a sure hardness) and last set time (when urgent the floor with a heavy object leaves no indentation). Compare the check effects with the manufacturer’s specifications—if the deviation exceeds 30%, the product great can also be unqualified.

3. Fiber and Cement Ratio Inspection: The Basis of Cement Blanket Stability

Cement blanket is a composite cloth composed of high-strength glass fiber or polyester fiber and hydraulic cement. The rationality of the fiber-cement ratio immediately impacts the tensile strength, flexibility, and crack resistance of the product. Inferior merchandise frequently reduce corners by means of decreasing fiber content material or the usage of low-quality recycled fibers, ensuing in terrible stability.

3.1 Check Fiber Distribution and Content

Take a small area of cement blanket and cautiously peel off the floor layer. High-quality merchandise will have uniform fiber distribution—you can see dense, non-stop fibers intertwined, except apparent agglomeration or clean areas. For quantitative testing, you can use the ignition method: weigh the dry pattern (weight W1), warmth it in a muffle furnace at 600℃ for 30 minutes (to burn off the fibers), then weigh the ultimate cement (weight W2). The fiber content material is calculated as (W1-W2)/W1×100%. The wellknown fiber content material of cement blanket ought to be 8-12%—too low will limit tensile strength, and too excessive will have an effect on the bonding between fiber and cement.

3.2 Verify Fiber and Cement Quality

In addition to the ratio, the first-rate of fibers and cement is equally important. Ask the producer to grant the fiber kind certificate—high-quality cement canvas commonly makes use of alkali-resistant glass fiber, which can face up to the erosion of cement hydration merchandise and keep away from fiber embrittlement. For cement, test the company and batch variety of the cement used, and affirm whether or not it meets the necessities of Portland cement GB175-2007. You can additionally take the cement powder peeled from the pattern to check its fineness and putting time—coarse cement powder or atypical placing time suggests terrible cement quality.

4. Appearance and Durability Intuitive Detection: Identify Defects at a Glance

Appearance inspection is the easiest and most direct technique for preliminary nice judgment. Many great issues of cement blanket can be mirrored thru appearance, and subsequent sturdiness can additionally be inferred from some look characteristics.

4.1 Key Points of Appearance Inspection

When unpacking, first test the usual roll of cement blanket: the packaging must be intact, except moisture or mildew (moisture will reason untimely setting). Unroll the product and take a look at the surface—there have to be no uneven thickness, uncovered fibers, or cement agglomeration. The aspect need to be neat except free threads. For coloured cement blanket, the colour must be uniform besides apparent colour difference.

4.2 Simple Durability Test

Take a small pattern and soak it in water for seventy two hours—qualified cement blanket will now not peel off or deform. Then, region the pattern in a high-temperature surroundings (50℃) for forty eight hours, and then in a low-temperature environment (-10℃) for forty eight hours. After thermal cycling, test for cracks—high-quality merchandise have excellent temperature resistance. In addition, you can rub the floor of the cured pattern with sandpaper—there have to be no apparent cement powder falling off, which suggests appropriate floor compactness.

Final Buyer’s Checklist: Don’t Miss These Key Steps

1. Ask the producer for check reviews of compressive electricity (≥20MPa at 28 days) and treatment time (initial set 2-4h, ultimate set 6-12h);

2. Conduct on-site sampling to take a look at fiber content material (8-12%) and distribution uniformity;

3. Check look for moisture, uncovered fibers, and uneven thickness;

4. Perform easy checks (hammer tapping, water soaking, thermal cycling) to confirm power and durability.

Choosing excellent cement blanket or cement canvas is the premise of making sure assignment quality. By following this trying out checklist, you can efficaciously keep away from inferior merchandise and maximize the fee of your development investment. If you have greater questions about cement blanket pleasant testing, experience free to go away a remark below!

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province