Geotextile Tubes Dimensions for Shoreline Protection: What You Need to Know

Shoreline erosion poses a crucial danger to coastal communities, infrastructure, and ecosystems. Among the most superb solutions, coastal geotextile tubes have emerged as a durable, eco - pleasant preference for protecting seashores from wave action, tides, and storm surges. These engineered structures, regularly referred to in reality as geotextile tube systems, matter closely on perfect dimensioning to supply optimum performance. From diameter and size to thickness, each dimension affects their potential to face up to coastal forces. Let’s discover 5 key elements of geotextile tube dimensions for profitable shoreline protection.

1. Key Factors Influencing Dimension Selection for Coastal Geotextile Tubes

Choosing the proper dimensions for coastal geotextile tubes isn’t a one - measurement - suits - all process. Several web site - unique elements ought to information the choice to make certain the tubes can manage neighborhood coastal conditions.

Wave electricity is the foremost consideration: excessive - strength coasts with large, common waves require larger, thicker tubes to face up to impact. Tidal vary additionally matters—areas with excessive tides want tubes tall ample to hold safety at some stage in each excessive and low water levels. Soil kind is every other factor; tubes stuffed with nearby sediment or sand should have dimensions that accommodate the material’s weight and compaction properties. Additionally, the project’s goal—whether erosion control, seaside nourishment, or flood prevention—affects sizing. For example, Flood Barriers built-in with geotextile tubes demand wider bases for steadiness for the duration of storm surges. By inspecting these factors, engineers can pick dimensions that stability strength, cost, and environmental compatibility.

2. Diameter: Balancing Stability and Wave Resistance

The diameter of a geotextile tube is a integral dimension that immediately affects its steadiness and capability to dissipate wave energy. In shoreline protection, large diameters commonly supply higher resistance to robust currents and waves.

Tubes with diameters ranging from three to 6 toes are frequent for average - electricity coasts, supplying a steady base to take in wave have an effect on besides immoderate cloth use. For excessive - power environments, such as uncovered ocean shorelines, diameters of eight to 12 ft may additionally be quintessential to stop displacement. A large diameter additionally will increase the tube’s weight when filled, bettering its capability to remain anchored in place. However, outsized diameters can complicate transportation and installation, particularly in far off coastal areas. Engineers frequently choose for modular designs, combining a couple of medium - diameter tubes, to obtain the favored steadiness whilst preserving practicality.

3. Length: Coverage and Installation Efficiency

The size of coastal geotextile tubes determines how a whole lot shoreline they can defend in a single installation, affecting each insurance and assignment efficiency. Longer tubes minimize the quantity of joints needed, minimizing vulnerable factors the place erosion ought to occur.

For non-stop shoreline protection, tubes ranging from 50 to one hundred ft in size are typical, permitting crews to cowl giant stretches quickly. In areas with irregular seashores or rocky terrain, shorter lengths (20 to forty feet) provide greater flexibility to comply with the coast’s herbal contours. Length additionally affects handling: longer tubes require specialised tools for transportation and deployment, such as cranes or roll - off trucks. When designing a project, balancing size with web site accessibility ensures that the tubes can be hooked up successfully besides compromising coverage.

4. Thickness and Material Strength: Ensuring Longevity

While now not a linear dimension, the thickness of the geotextile fabric used in the tubes is carefully linked to their structural integrity and lifespan in coastal environments. Thicker, excessive - energy fabric face up to punctures, UV degradation, and abrasion from sand and waves.

Coastal geotextile tubes designed for lengthy - time period safety generally use fabric with a thickness of 10 to 20 mils, strengthened with woven or non - woven polypropylene fibers. This thickness ensures the tubes can stand up to repeated wave influences and the weight of crammed cloth over time. In saltwater environments, the place corrosion is a risk, thicker substances additionally grant a barrier towards chemical degradation. For transient or emergency protection, such as reinforcing Flood Barriers in the course of storm seasons, lighter substances may also suffice, however they require extra everyday inspection. Matching fabric thickness to the tube’s diameter and meant lifespan is key to warding off untimely failure.

5. Height and Stacking: Adapting to Changing Coastal Conditions

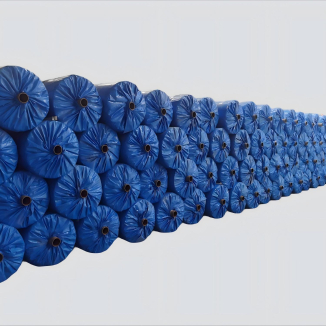

Shorelines are dynamic, with transferring sands, rising sea levels, and various storm intensities. The top of geotextile tube installations, frequently done through stacking tubes in layers, lets in for adaptability to these altering conditions.

A single layer of tubes offers baseline safety for low - mendacity coasts with minimal erosion risk. In areas inclined to storm surges, stacking two or three layers creates a taller barrier, growing the elevation of protection. For example, stacking four - foot diameter tubes can create a 12 - foot tall shape succesful of blocking off giant floodwaters when built-in with Flood Barriers. The spacing between stacked layers is additionally critical—tighter spacing enhances stability, whilst mild gaps permit for drainage and limit hydrostatic pressure. By designing adjustable peak configurations, engineers make sure the tubes can evolve with the coast, supplying lengthy - time period safety as prerequisites change.

Conclusion

Proper dimensioning is the basis of high quality shoreline safety with coastal geotextile tubes. From diameter and size to cloth thickness and stacking height, every dimension need to be tailor-made to website - particular conditions, consisting of wave energy, tidal range, and mission goals. By deciding on the proper dimensions, engineers can maximize the stability, wave resistance, and toughness of geotextile tube systems, whether or not used for erosion control, seashore restoration, or reinforcing Flood Barriers. For coastal communities in search of durable, sustainable protection, appreciation these dimensional issues is the first step towards constructing resilient seashores that stand the check of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province