Geomembranes for Oil & Gas Industry: Leak Prevention & Cost Savings

The oil and gas employer operates under stringent environmental pointers and faces day-to-day stress to restrict operational dangers at the equal time as optimizing costs. Among the most integral challenges is stopping leaks from storage tanks, containment ponds, and drilling pads, which can lead to soil contamination, groundwater pollution, and hefty regulatory fines. Geomembranes—synthetic liners engineered for impermeability and durability—have emerged as a cornerstone reply for leak prevention, imparting a combo of technical common common performance and monetary efficiency. This article explores how geomembranes, specially HDPE membrane sheets, are remodeling protection and cost administration in the electrical strength sector.

Why Geomembranes Are Essential for Oil & Gas Operations

Geomembranes are polymeric sheets designed to act as boundaries towards liquids, gases, and chemicals. In the oil and fuel industry, their predominant feature is to line secondary containment systems, such as frac pits, furnace retention ponds, and drilling pad liners, making effective that hazardous belongings proceed to be remoted from the surrounding environment.

1. Preventing Environmental Disasters

A single leak from an unlined storage tank or containment neighborhood can launch thousands of gallons of crude oil, brine, or wastewater into the soil, contaminating aquifers and ecosystems. Geomembrane sheets supply a zero-permeability layer that stops drinks from seeping into the ground. For instance, HDPE membrane sheets, made from high-density polyethylene, are quite used due to their resistance to hydrocarbons, acids, and alkalis. Their low water vapor permeability coefficient (≤1.0×10⁻¹³ cm/cm²·s·Pa) ensures long-term containment, even in aggressive chemical environments.

2. Complying with Regulations

Governments global mandate secondary containment constructions for oil and gasoline services to meet environmental protection standards. Geomembranes assist operators adhere to insurance plan insurance policies like the U.S. EPA’s Spill Prevention, Control, and Countermeasure (SPCC) suggestions with the aid of the use of developing a reliable barrier between saved drinks and the environment. Failure to comply can stop cease end result in fines exceeding $50,000 per day, making geomembranes a competitively priced insurance plan graph layout insurance plan in opposition to reformatory and reputational damage.

3. Reducing Operational Downtime

Leaks regularly stress shutdowns for cleanup and remediation, disrupting manufacturing and incurring considerable losses. Geomembrane-lined containment constructions reduce this risk with the resource of the utilization of stopping spills from escaping containment areas. For example, a lined drilling pad can embody drilling mud and cuttings except soil erosion or groundwater contamination, keeping off high priced delays in true completion.

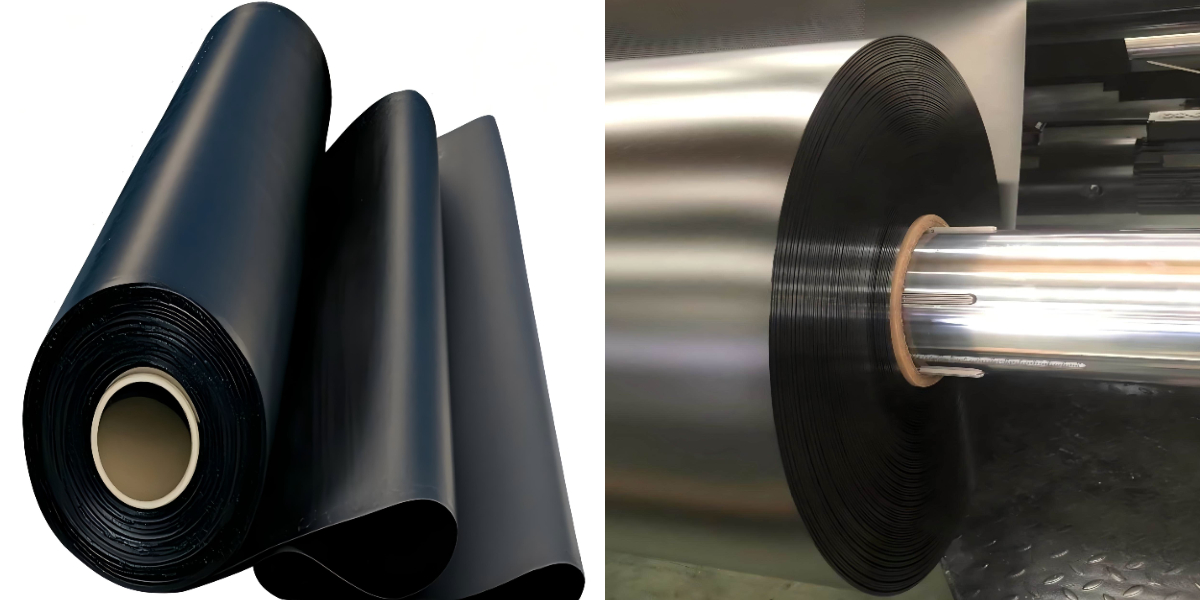

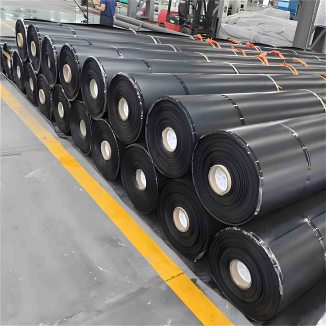

HDPE Membrane Sheets: The Industry Standard for Durability

High-density polyethylene (HDPE) geomembranes dominate the oil and fuel area due to their chemical resistance, mechanical strength, and longevity. Here’s why they outperform choice materials:

1. Superior Chemical Resistance

HDPE membranes are inert to most hydrocarbons, consisting of crude oil, diesel, and gasoline, as excellent as corrosive belongings like brine and hydraulic fracturing fluids. This resistance stems from their non-polar molecular structure, which repels polar and non-polar chemical compounds alike. Unlike PVC or EPDM liners, HDPE does now no longer swell, degrade, or leach elements when uncovered to petroleum products, making positive many years of dependable service.

2. High Tensile Strength and Puncture Resistance

Oilfield operations encompass heavy machinery, sharp tools, and abrasive materials, all of which pose dangers to containment liners. HDPE membrane sheets are engineered with tensile strengths exceeding 25 MPa and elongation prices up to 700%, enabling them to stretch without tearing underneath stress. Their puncture resistance (≥187 N for 1.5mm thickness) in addition protects towards unintended harm from dropped equipment or rock fragments.

3. UV and Thermal Stability

Exposure to daylight hours hours and excessive temperatures can degrade polymers over time. HDPE membranes embody carbon black stabilizers that soak up UV radiation, stopping chain scission and embrittlement. They in addition maintain flexibility at temperatures as low as -40°C and stand up to warmness up to 110°C, making them gorgeous for desert, arctic, and offshore environments.

4. Longevity and Cost Efficiency

HDPE geomembranes have an estimated provider existence of 50–70 years when buried and 20+ years when uncovered to sunlight. This sturdiness reduces the pick for generic replacements, decreasing lifecycle costs in difference to clay liners or concrete containment systems, which are inclined to cracking and require every day maintenance. Additionally, HDPE’s low coefficient of thermal expand minimizes wrinkling or stretching at some element of temperature fluctuations, making sure regular performance.

Applications of Geo Membrane Sheets in Oil & Gas

Geomembranes are versatile sufficient to deal with higher than one containment challenges in the route of the power sector:

1. Secondary Containment for Storage Tanks

Double-walled tanks with geomembrane liners supply redundant safety in the route of leaks. If the predominant tank fails, the lined secondary containment location captures spills, stopping environmental release. This setup is obligatory for above-ground storage tanks (ASTs) protecting greater than 1,320 gallons of oil in the U.S.

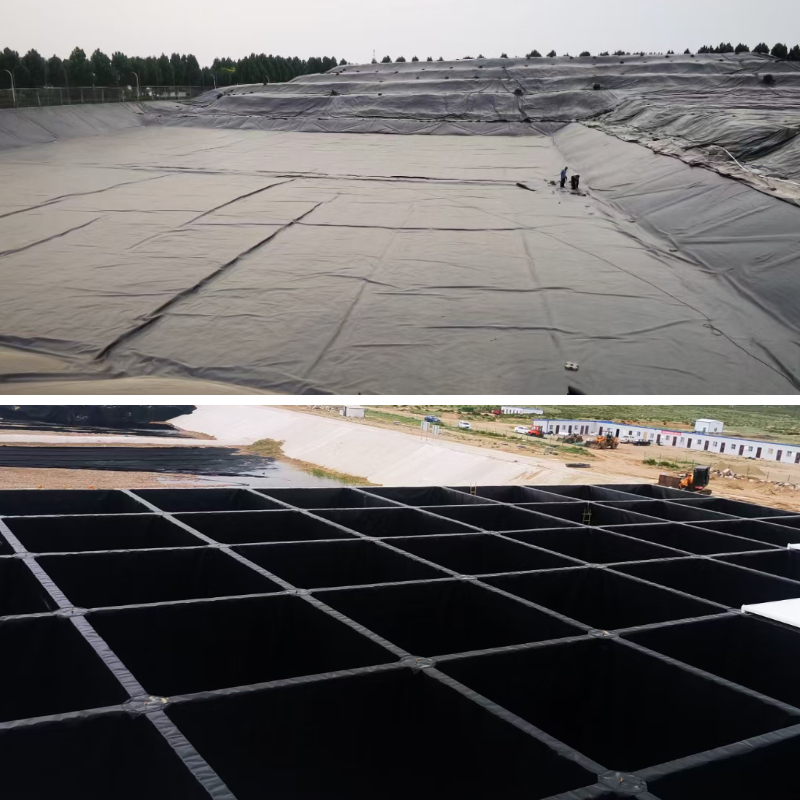

2. Frac Water and Flowback Ponds

Hydraulic fracturing requires loads of thousands of gallons of water blended with chemical elements and sand. Geomembrane-lined ponds store this fluid at some element of drilling and completion, stopping seepage into groundwater. HDPE’s resistance to fracking chemical compounds ensures the liner stays intact for the size of the process.

3. Drilling Mud and Cuttings Management

Drilling operations generate waste mud and rock cuttings contaminated with hydrocarbons and heavy metals. Lining reserve pits with geomembranes isolates these wastes from soil and water, simplifying cleanup and decreasing remediation costs.

4. Pipeline Corrosion Protection

While no longer a imperative application, geomembranes can be used as cathodic safety boundaries under pipelines to quit stray cutting-edge corrosion. Their electrical insulation homes shield buried steel pipes from electrolytic damage, extending pipeline lifespan.

Cost Savings Through Geomembrane Adoption

Investing in geomembranes yields measurable monetary benefits:

1. Lower Installation Costs

Modern HDPE membranes are manufactured in massive rolls (up to eight meters), decreasing the big vary of seams required at some component of installation. Advanced hot-melt welding strategies create hermetic joints in minutes, decreasing labor prices via the use of up to 40% in difference to ordinary factors like clay or concrete.

2. Reduced Maintenance Expenses

Geomembrane-lined constructions require minimal upkeep. Unlike earthen ponds, which opt for often taking location dredging to put off sediment, lined ponds hold their viable indefinitely. Additionally, HDPE’s resistance to herbal increase (e.g., algae, bacteria) eliminates the desire for chemical treatments.

3. Avoidance of Fines and Cleanup Costs

A single oil spill can fee a lot of thousands in cleanup, penal complex fees, and regulatory penalties. Geomembranes act as a proactive safeguard, stopping spills from escalating into environmental disasters. For example, a 2019 hit upon out about positioned that choices the utilization of HDPE liners reduced spill-related charges through way of 78% in big difference to unlined sites.

4. Enhanced Resource Efficiency

In water-scarce regions, geomembranes allow water recycling thru the utilization of stopping loss from evaporation ponds. Lined ponds decrease water loss via way of up to 95%, permitting operators to reuse flowback water in subsequent fracking stages, reducing freshwater procurement costs.

Conclusion: The Future of Leak Prevention in Oil & Gas

Geomembranes, specifically HDPE membrane sheets, have redefined security and price administration in the oil and gasoline industry. Their viable to face up to harsh chemicals, mechanical stress, and environmental extremes makes them necessary for brand new containment systems. By adopting geomembrane technology, operators can reap zero-leak operations, comply with regulations, and launch proper sized economic monetary financial savings over the lifecycle of their facilities.

As the power place evolves nearer to stricter environmental requirements and sustainable practices, geomembranes will proceed to be at the forefront of leak prevention solutions. Their examined track record, blended with ongoing improvements in cloth science, ensures they will proceed to guard ecosystems whilst optimizing operational effectivity for a prolonged time to come.

Key Takeaways:

Geomembranes furnish a cost-effective, prolonged lasting barrier in opposition to leaks in oil and gasoline containment systems.

HDPE membrane sheets are the enterprise manufacturer new due to their chemical resistance, mechanical strength, and longevity.

Applications span storage tanks, frac ponds, drilling sites, and pipeline protection.

Adoption reduces installation, maintenance, and spill-related fees even as making effective regulatory compliance.

For operators searching for to future-proof their facilities, investing in extraordinary geomembrane constructions is no longer absolutely a security measure—it’s a strategic financial decision.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province