Concrete Impregnated Fabric vs. Traditional Concrete: A Comparison

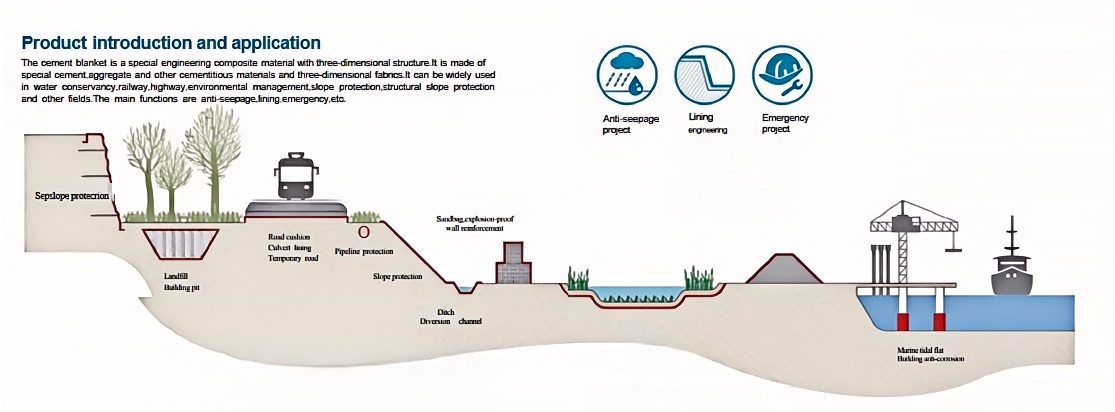

When it comes to construction, repair, or structural reinforcement, concrete has lengthy been the go-to material. But in current years, concrete impregnated fabric—including editions like concrete fabric and Ditch Liner Material material—has emerged as a flexible, environment friendly alternative. While each serve the core motive of growing strong, long lasting structures, their properties, applications, and overall performance range significantly. This information compares concrete impregnated cloth and usual concrete throughout key categories, assisting you decide which is higher appropriate for your project. We’ll damage down their set up processes, durability, cost-effectiveness, and perfect uses, making sure you make an knowledgeable choice.

What Are the Two Materials, Exactly?

Before diving into comparisons, let’s make clear what every fabric is.

Concrete impregnated material is a composite fabric that combines a woven or non-woven material matrix with a dry concrete mix. The textile—typically polypropylene or polyester—acts as a service and reinforcement, whilst the concrete combine hardens when activated with water. Concrete material is a frequent kind of this fabric, recognized for its lightweight, rollable structure that conforms to irregular surfaces. Ditch Liner Material fabric regularly refers to higher-grade versions designed for traumatic applications, with more advantageous tensile electricity and climate resistance.

Traditional concrete, on the different hand, is a combination of cement, aggregates (sand, gravel), water, and every now and then additives. It’s blended on-site or delivered ready-mix, poured into forms, and hardens over time to create rigid, monolithic structures. It’s been used for centuries in the whole thing from structures to roads due to its uncooked strength.

Installation: Flexibility vs. Formwork

One of the largest variations between concrete impregnated cloth and normal concrete lies in installation— a issue that closely influences undertaking time and labor.

Concrete Impregnated Fabric Installation:Concrete material and Ditch Liner Material cloth are highly convenient to install. They arrive in rolls, which can be reduce to dimension with scissors or a utility knife. The cloth is draped, wrapped, or laid over the goal surface—whether it’s a curved pipe, steep slope, or vertical wall. Activation genuinely requires spraying or misting with water; no mixing, pouring, or heavy tools is needed. Within hours, the cloth hardens into a inflexible structure. This makes it best for hard-to-reach areas (like far flung slope repairs) or initiatives the place pace is critical.

Traditional Concrete Installation: Traditional concrete requires large preparation. First, formwork (wooden or metallic frames) ought to be constructed to comprise the moist concrete. The concrete is then blended (either on-site or delivered) and poured into the forms, which have to be vibrated to cast off air bubbles. After pouring, the concrete wishes days to cure—formwork can’t be eliminated for at least 24-48 hours, and full energy takes weeks. This method is labor-intensive, time-consuming, and requires specialised equipment (mixers, vibrators) and knowledgeable workers.

Durability: Composite Strength vs. Rigid Toughness

Durability is a key consideration for any development material, and each alternatives have wonderful strengths.

Concrete Impregnated Fabric Durability: Concrete impregnated material advantages from composite strength. The material matrix provides tensile energy to the concrete, which is naturally robust in compression however susceptible in tension. This capacity the material resists cracking and can face up to minor actions (like thermal enlargement or floor shifting) except breaking. Ditch Liner Material cloth frequently consists of UV stabilizers and chemical-resistant coatings, making it long lasting in harsh environments—from coastal salt spray to industrial chemical exposure. While it may additionally no longer healthy standard concrete’s uncooked compressive strength, its flexibility makes it extra resilient in dynamic conditions.

Traditional Concrete Durability: Traditional concrete has unmatched compressive strength—making it best for load-bearing constructions like constructing foundations or bridges. However, it’s brittle and inclined to cracking when subjected to anxiety or movement. Cracks can permit water to seep in, main to freeze-thaw injury in bloodless climates or corrosion of embedded metal reinforcement. To mitigate this, extra steps like including rebar or making use of sealants are regularly needed, growing fee and complexity.

Cost: Upfront vs. Long-Term

Cost comparisons rely on assignment measurement and scope, however there are clear developments in upfront and long-term expenses.

Concrete Impregnated Fabric Cost: Concrete fabric and Ditch Liner Material fabric have a greater upfront fee per rectangular meter than common concrete. However, this is regularly offset with the aid of decrease labor and gear costs. Since set up is quickly and requires few workers, whole assignment prices can be lower—especially for small to mid-sized initiatives or these in hard-to-reach areas. Additionally, the fabric’s sturdiness reduces upkeep charges over time, as it’s much less inclined to cracking and damage.

Traditional Concrete Cost: Traditional concrete has a decrease upfront fabric cost, however labor and formwork costs pressure up complete costs. For massive tasks (like highways or buildings), economies of scale can make it extra cost-effective. However, protection charges are higher—cracks want to be repaired, sealants reapplied, and in some cases, complete sections changed if injury is severe.

Ideal Applications: When to Choose Which

The proper cloth depends on your project’s special needs. Here’s how to in shape every to frequent applications:

Concrete Impregnated Fabric Applications

Concrete impregnated cloth shines in tasks the place flexibility, speed, or get entry to is a challenge. Key makes use of include: emergency repairs (pipe leaks, potholes, collapsed protecting walls), slope stabilization and erosion manipulate (steep hillsides, riverbanks), transient constructions (military bunkers, catastrophe shelters), and repairs to irregular surfaces (curved culverts, broken equipment bases). Ditch Liner Material cloth is additionally used in environmental projects, like lining drainage ditches to stop erosion whilst permitting vegetation to develop through.

Traditional Concrete Applications

Traditional concrete is nevertheless the quality preference for load-bearing, everlasting structures. Common functions include: constructing foundations and walls, highways, bridges, dams, and large-scale infrastructure (airport runways, stadiums). It’s additionally desired for tasks the place uncooked compressive electricity is non-negotiable—like industrial flooring that want to guide heavy machinery.

Environmental Impact: Waste vs. Sustainability

In an generation of eco-conscious construction, environmental have an impact on is increasingly more important.

Concrete Impregnated Fabric Impact: Concrete impregnated material is extra sustainable in quite a few ways. It requires much less water to spark off than regular concrete makes use of for mixing. The light-weight rolls limit transportation emissions (fewer vans are wanted to supply the equal coverage). Additionally, in view that no formwork is required, there’s much less waste from timber or metallic frames. Some Ditch Liner Material cloth even makes use of recycled textiles, similarly reducing its carbon footprint.

Traditional Concrete Impact: Traditional concrete has a substantial environmental footprint. Cement manufacturing by myself money owed for a giant component of international CO2 emissions. The fabric is heavy, so transportation emissions are high. Formwork waste is additionally a concern—much of it ends up in landfills after use. While efforts are being made to limit its affect (like the use of recycled aggregates), it stays much less eco-friendly than concrete cloth.

Conclusion: Choose Based on Project Needs

Concrete impregnated cloth (including concrete fabric and Ditch Liner Material material) and standard concrete are each precious materials—but they serve exceptional purposes. Concrete impregnated cloth is perfect for fast, flexible, and sustainable initiatives the place get right of entry to is confined or minor motion is expected. Traditional concrete excels in permanent, load-bearing constructions the place uncooked energy is critical.

When deciding, reflect onconsideration on your project’s timeline, budget, location, and sturdiness requirements. For emergency repairs, slope stabilization, or irregular surfaces, concrete impregnated cloth is the smarter choice. For foundations, bridges, or large-scale infrastructure, common concrete stays unmatched. By appreciation their strengths and weaknesses, you can pick out the cloth that promises the high-quality effects for your particular needs.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province