Concrete Impregnated Fabric vs. Traditional Concrete: Cost and Performance Comparison

In the world of construction, selecting the proper cloth can make or destroy a project’s timeline, budget, and durability. Two famous preferences that frequently stand out are concrete impregnated cloth (including improvements like Flexible Concrete Blanket and Cement Impregnated Fabric) and normal concrete. While normal concrete has been a staple for centuries, contemporary preferences like Cement canvas are gaining traction for their special advantages. This article compares these substances throughout cost, installation, performance, and use instances to assist contractors, engineers, and assignment managers make knowledgeable decisions.

What Are Concrete Impregnated Fabrics?

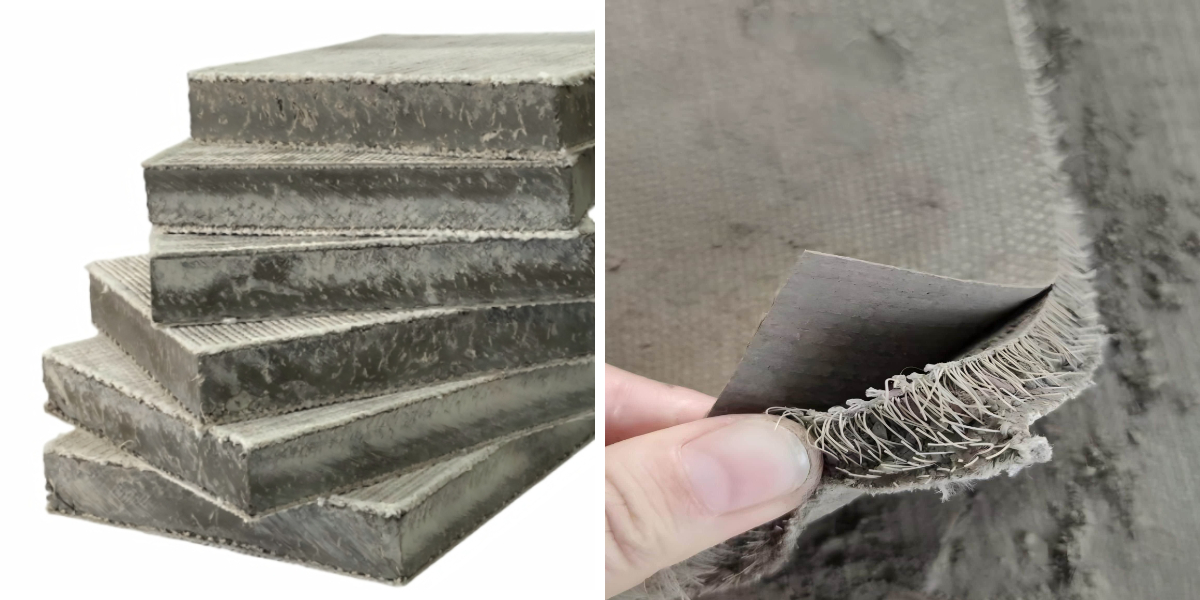

Concrete impregnated fabrics, such as Cement Impregnated Fabric and Cement canvas, are modern substances designed to mix the energy of concrete with the flexibility of textiles. These merchandise consist of a woven material (typically made from polypropylene or glass fiber) pre-impregnated with a dry cementitious mixture. When activated with water, the cloth hardens into a durable, inflexible structure.

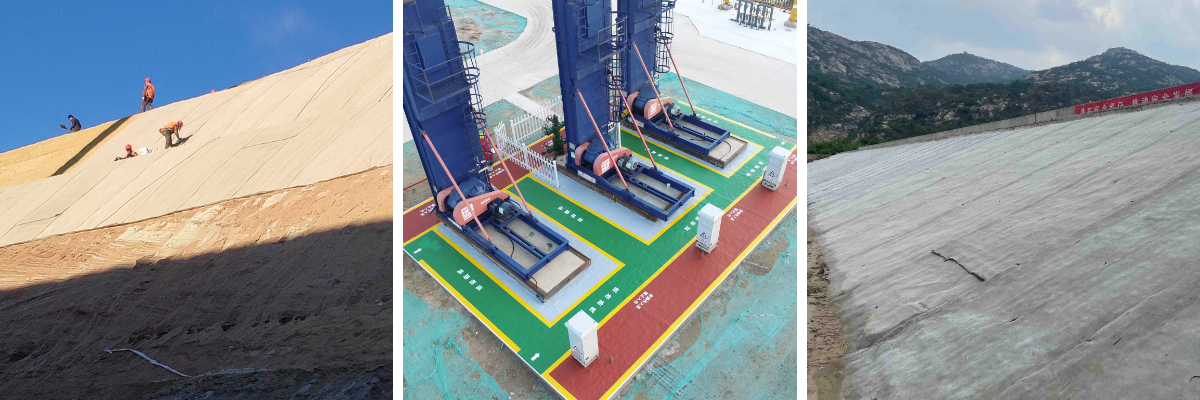

A key instance is the Flexible Concrete Blanket, a rollable fabric that can be reduce to size, draped over surfaces, and formed to suit curves or irregular contours. Once hydrated, it treatment options into a sturdy concrete layer, doing away with many of the challenges related with mixing and pouring normal concrete.

Traditional Concrete: The Tried-and-True Standard

Traditional concrete is a combination of cement, aggregates (sand, gravel), water, and frequently components to beautify energy or workability. It has been used for millennia in buildings ranging from bridges to buildings, relying on on-site mixing, formwork, and curing to gain its strength. While effective, its software is labor-intensive and weather-dependent, with strict necessities for mixing ratios and curing conditions.

Cost Comparison: Upfront and Long-Term Expenses

Material Costs

Concrete Impregnated Fabric: Products like Cement Impregnated Fabric and Cement canvas normally price8–15 per rectangular foot, relying on thickness and reinforcement. Flexible Concrete Blanket, designed for speedy installations, falls at the greater cease due to its convenience.

Traditional Concrete: Costs3–7 per rectangular foot for substances alone, however this excludes formwork, which provides2–5 per rectangular foot.

Installation Costs

Concrete Impregnated Fabric: Requires fewer employees and no formwork. Labor fees common

2–4 per rectangular foot, with set up instances up to 50% quicker than ordinary methods. A 1,000-square-foot assignment the use of Flexible Concrete Blanket can be executed in 1–2 days.

Traditional Concrete: Labor expenses vary from 5–10 per rectangular foot, such as mixing, pouring, and formwork removal. Larger tasks can also take weeks, growing labor expenses.

Long-Term Savings

While typical concrete has decrease upfront cloth costs, Concrete Impregnated Fabric regularly gives financial savings in labor and downtime. For example, Cement canvas requires minimal protection and resists cracking in harsh climates, lowering restore expenses over time.

Performance: Durability, Flexibility, and Adaptability

Strength and Durability

Concrete Impregnated Fabric: When cured, Cement Impregnated Fabric achieves compressive strengths of 3,000–5,000 psi, same to normal concrete. Cement canvas, bolstered with fibers, excels in tensile strength, making it best for erosion manage or slope stabilization.

Traditional Concrete: Compressive strengths vary from 2,500–8,000 psi, however it is susceptible to cracking beneath motion or freeze-thaw cycles besides suited reinforcement.

Flexibility and Versatility

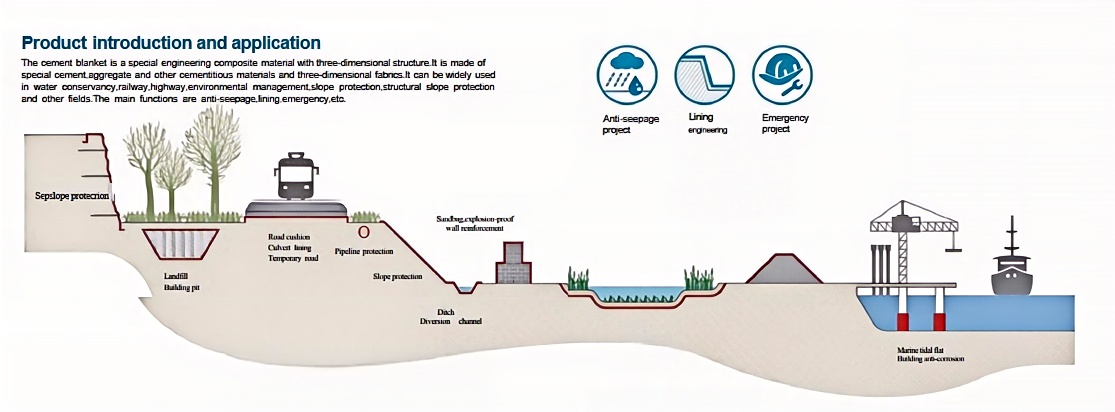

Concrete Impregnated Fabric: Flexible Concrete Blanket conforms to uneven surfaces, making it best for repairing pipelines, lining ditches, or protecting curved structures. It adapts to minor floor shifts, reducing cracking risks.

Traditional Concrete: Rigid and inflexible, requiring unique formwork to gain preferred shapes. It struggles with uneven terrain, regularly main to gaps or vulnerable points.

Weather Resistance

Concrete Impregnated Fabric: Cement canvas treatments rapidly even in low temperatures and resists water penetration as soon as set, making it appropriate for moist environments.

Traditional Concrete: Curing is delayed in bloodless or wet weather, growing the threat of weakening. It can also require waterproofing remedies to forestall moisture damage.

Ideal Use Cases for Each Material

1.When to Choose Concrete Impregnated Fabric

Emergency Repairs: Flexible Concrete Blanket can be deployed hastily to restore leaks or stabilize constructions after storms.

Remote Locations: Cement Impregnated Fabric is light-weight and convenient to transport, heading off the want for heavy mixing equipment.

Erosion Control: Cement canvas liners guard riverbanks or slopes with minimal environmental disruption.

Curved or Irregular Surfaces: The adaptability of these fabric eliminates the want for customized formwork.

2.When to Stick with Traditional Concrete

Large-Scale Structures: Bridges, foundations, or high-rise constructions gain from typical concrete’s excessive compressive strength.

Static, Flat Surfaces: Floors, sidewalks, or driveways the place stress is an gain and formwork is straightforward.

Budget-Conscious Projects: Small, flat initiatives with sufficient time for set up may also prioritize decrease fabric costs.

Environmental Impact: Sustainability Considerations

Concrete Impregnated Fabric regularly has a smaller carbon footprint. Cement canvas makes use of up to 90% much less water than common concrete all through set up and reduces waste, as it is reduce to actual sizes. Traditional concrete, meanwhile, requires giant water utilization and generates waste from formwork and extra material.

Conclusion: Making the Right Choice

Concrete Impregnated Fabric, inclusive of Flexible Concrete Blanket, Cement Impregnated Fabric, and Cement canvas, affords speed, flexibility, and long-term sturdiness for precise applications, notwithstanding greater upfront cloth costs. Traditional concrete stays within your budget for large, inflexible constructions the place energy and familiarity are key.

By evaluating venture needs—whether it’s fast installation, adaptability to terrain, or long-term maintenance—contractors can pick the cloth that balances fee and performance. For many present day projects, the innovation of concrete impregnated fabric is proving to be a game-changer in efficiency and sustainability.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province