Case Study: How Geocell Reinforced a Highway Construction Project

In the realm of present day infrastructure development, motorway building faces steady challenges—from unstable subgrades to environmental constraints and the want for long-term durability. For one mid-sized dual carriageway growth mission in a rural-urban transition area, these challenges have been in particular acute. The undertaking aimed to widen a 12-kilometer stretch of two-lane motorway to 4 lanes, however the site’s smooth soil subgrade, excessive rainfall, and hazard of soil erosion threatened to lengthen timelines and expand costs. That’s the place geocell technological know-how stepped in, alongside specialised variations like geocell silknet and perforated geocell, to radically change the project’s trajectory. This case find out about breaks down how geocell options addressed crucial ache points, expanded building efficiency, and delivered a extra resilient highway.

1. Project Background: The Challenges of Soft Soil and Environmental Pressure

The dual carriageway in query connects a developing suburban vicinity to a important city, carrying over 15,000 automobiles daily—well past its unique capacity. The enlargement used to be urgent, however the undertaking web site introduced two essential obstacles:

First, the subgrade consisted of soft, compressible soil. Traditional development techniques (like over-excavation and changing soil with gravel) would have required casting off over 50,000 cubic meters of earth, growing truck traffic, carbon emissions, and costs. Second, the area receives heavy annual rainfall, which intended the subgrade was once inclined to waterlogging and erosion—risks that ought to lead to pavement cracking or sinking inside a few years of opening.

The task group wanted a answer that would:

Stabilize the tender subgrade besides great excavation;

Improve water drainage to stop erosion;

Reduce building time and environmental impact;

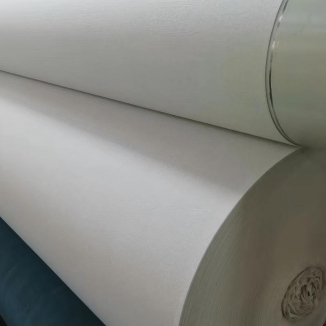

Ensure the motorway may want to face up to heavy masses (including industrial trucks) for decades. After evaluating choices like geotextiles and stone columns, the group chosen geocell systems—specifically geocell silknet for more desirable tensile energy and perforated geocell to raise drainage.

2. Why Geocell Was the Right Choice: Key Advantages Over Traditional Methods

To apprehend why geocell emerged as the most desirable solution, it’s vital to examine its overall performance to typical approaches. Traditional gentle soil stabilization frequently depends on “cut-and-fill,” the place susceptible soil is dug up and changed with more advantageous cloth (e.g., beaten stone). This approach is now not solely labor-intensive and pricey however additionally disrupts neighborhood ecosystems—especially in the project’s ecologically touchy zones.

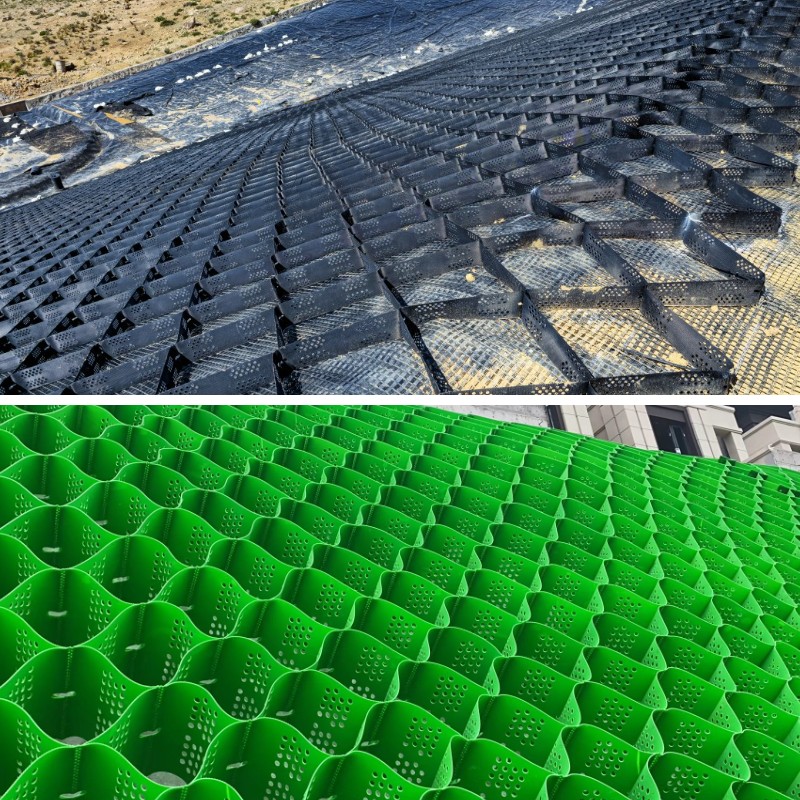

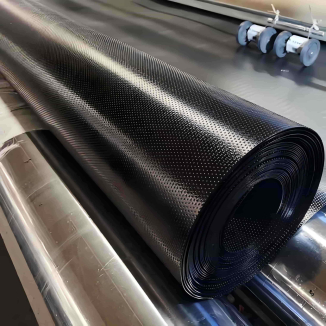

Geocell, by using contrast, is a three-dimensional, honeycomb-like shape made from high-density polyethylene (HDPE) or polyester. When elevated and crammed with mixture (like gravel or sand), it distributes masses evenly throughout the subgrade, lowering strain on smooth soil. For this project, two specialised geocell editions introduced special value:

Geocell silknet: This variant integrates a thin, high-strength silk-like mesh into the geocell walls, growing tensile resistance by means of up to 30% in contrast to preferred geocell. This was once crucial for the highway’s outer lanes, which would undergo the brunt of heavy truck traffic.

Perforated geocell: Unlike solid-walled geocell, perforated geocell elements small holes in its walls. These holes permit extra rainwater to drain thru the geocell layer, stopping water from pooling in the subgrade and inflicting erosion or soil softening.

In assessments carried out with the aid of the project’s engineering team, the geocell machine decreased subgrade agreement with the aid of 65% in contrast to the cut-and-fill method. It additionally reduce building time through 20%—a fundamental win, as the dual carriageway wished to reopen to site visitors earlier than the begin of the region’s busy excursion season.

3. Implementation Process: From Site Prep to Geocell Installation

The profitable integration of geocell into the toll road challenge observed a structured, step-by-step process, overseen via a crew of geotechnical engineers and development managers. Here’s a special breakdown of how the work unfolded:

3.1 Site Preparation and Subgrade Assessment

First, the crew performed a thorough geotechnical survey to map the gentle soil zones. Using ground-penetrating radar (GPR) and soil samples, they recognized areas the place the subgrade’s bearing potential used to be lowest—these grew to be the precedence zones for geocell installation. The web site used to be then cleared of vegetation, and the current pavement was once milled (removed in layers) to expose the subgrade.

Next, the subgrade was once graded to make sure a stage surface. For areas with immoderate moisture, brief drainage ditches had been dug to decrease the water table—preparing the floor for perforated geocell set up later.

3.2 Geocell Unfolding and Anchoring

Once the subgrade used to be ready, the set up of geocell began. The group used trendy geocell for the internal lanes (lower visitors load) and geocell silknet for the outer lanes (higher site visitors load). Workers unfolded the flat geocell panels (which are shipped in compact rolls) and multiplied them into their honeycomb shape, securing the edges with metal stakes to stop transferring in the course of filling.

For the perforated geocell sections (installed in low-lying areas inclined to waterlogging), the crew ensured the holes had been aligned downward to maximize drainage. This alignment was once demonstrated the usage of laser degrees to keep away from any tilting that ought to block water flow.

3.3 Filling and Compaction

The multiplied geocell cells had been then crammed with beaten limestone aggregate—chosen for its sturdiness and capacity to interlock inside the geocell structure. The mixture was once delivered in 15-centimeter layers, with every layer compacted the use of a vibratory roller. This compaction step was once critical: it ensured the combination settled tightly inside the geocell walls, developing a rigid, load-bearing layer.

For the geocell silknet sections, the crew used a barely coarser combination (20-30mm) to beautify interlocking with the mesh, in addition boosting tensile strength. Post-compaction checks validated that the geocell-aggregate layer had a bearing ability of four hundred kPa—more than double the a hundred and eighty kPa required for the highway’s sketch load.

3.4 Pavement Layer Installation

Once the geocell-aggregate base used to be absolutely compacted and inspected, the crew moved on to putting in the pavement layers. A 10-centimeter asphalt base path was once laid first, accompanied by using a 5-centimeter floor direction (high-performance asphalt designed for heavy traffic). The perforated geocell layer persevered to work under the pavement, channeling rainwater into the project’s underground drainage device and stopping moisture buildup.

4. Post-Construction Results: Durability, Efficiency, and Cost Savings

Six months after the motorway reopened to traffic, the assignment group performed a follow-up evaluation to measure the overall performance of the geocell system. The effects surpassed expectations:

4.1 Minimal Settlement and Pavement Damage

Traditional highways constructed on tender soil regularly ride 5-10 centimeters of agreement inside the first year. For this project, the geocell-reinforced subgrade confirmed just 1-2 centimeters of settlement—well inside the industry’s perfect limits. There had been no signs and symptoms of pavement cracking, rutting, or unevenness, even in areas the place business vehicles often travel. The geocell silknet’s more suitable tensile energy used to be credited with resisting the lateral stress from heavy loads, maintaining the subgrade stable.

4.2 Improved Drainage and Erosion Control

The perforated geocell proved surprisingly fine at managing rainfall. During a post-construction storm (with 50mm of rain in 24 hours), the toll road confirmed no standing water—unlike close by sections of the ancient highway, which frequently flooded. Soil samples taken from underneath the geocell layer confirmed low moisture content, confirming that the perforated graph was once stopping waterlogging and erosion.

4.3 Significant Cost and Time Savings

By selecting geocell over cut-and-fill, the task saved about $300,000 in cloth and labor costs. The decreased excavation additionally reduce carbon emissions by means of 25% (from fewer truck trips), aligning with the region’s sustainability goals. Additionally, the 20% quicker development timeline intended the toll road reopened two weeks early, minimizing visitors congestion for nearby commuters.

5. Lessons Learned and Future Applications of Geocell in Highway Construction

This case learn about affords precious insights for engineers and mission managers working on toll road initiatives in difficult soil conditions. The key training include:

Geocell is versatile: Standard geocell, geocell silknet, and perforated geocell can be tailor-made to particular assignment needs—whether the precedence is load-bearing strength, drainage, or cost-effectiveness.

Early geotechnical surveys are critical: Mapping tender soil zones and moisture ranges upfront ensures geocell is set up the place it’s most needed, averting waste and maximizing performance.

Sustainability and effectivity go hand in hand: Geocell reduces the want for uncooked substances (like gravel for cut-and-fill) and lowers carbon emissions, making it a greener choice to regular methods.

Looking ahead, the use of geocell in toll road development is set to grow—especially as cities enlarge into areas with bad soil quality. Innovations like biodegradable geocell (for eco-sensitive projects) and geocell built-in with sensors (to screen subgrade fitness in actual time) ought to similarly decorate its value. For this project’s team, the success of the geocell device has already led to its resolution for a close by motorway ignore project—proving that geocell is greater than a transient fix, however a long-term answer for durable, environment friendly infrastructure.

Conclusion

This toll road building case learn about demonstrates how geocell—supported via specialised versions like geocell silknet and perforated geocell—can overcome the most frequent challenges of gentle soil, drainage, and cost. By stabilizing the subgrade, enhancing water management, and lowering building time, geocell delivered a toll road that is no longer solely more suitable and extra long lasting however additionally greater sustainable. For infrastructure initiatives going through comparable obstacles, geocell provides a proven, low in cost choice to ordinary methods—proving that innovation in development substances can flip challenges into possibilities for success.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province