Building with Sand: Geotextile Tubes for Land Reclamation and Dune Restoration

Coastal erosion and land loss are urgent international challenges, threatening infrastructure, ecosystems, and communities. In the combat in opposition to these forces, an modern and synergistic answer has emerged: combining one of Earth's most plentiful materials—sand—with superior engineering textiles. Geotextile tube technological know-how represents a pivotal approach for tender engineering, imparting a versatile, durable, and frequently extra environmentally adaptive method in contrast to usual tough structures. This article explores how these engineered structures are revolutionizing land reclamation and dune restoration tasks worldwide, presenting high-quality erosion manipulate and sustainable coastal management.

Understanding the Technology: How Geotextile Tubes Work

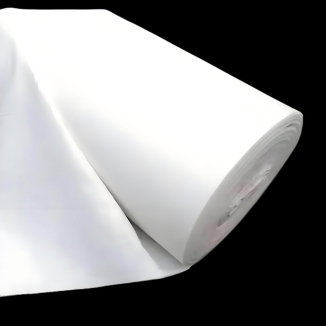

At its core, a geotextile tube is a large, elongated container made from high-strength, permeable artificial fabric. The precept is based in its simplicity: these tubes are strategically placed on-site and pumped full of a sand-water slurry, frequently dredged at once from close by waters or sourced from permitted locations. The permeable cloth acts as a filter, permitting water to drain out whilst conserving the stable sand and sediment particles inside. This process, recognized as sediment dewatering, is central to the technology's function. As the water escapes, the sediments consolidate, forming a solid, secure structure. The particular material houses are engineered for every project, balancing filtration rate, tensile strength, and UV resistance to create a sturdy barrier or core. The ensuing varieties are remarkably strong, succesful of withstanding wave forces, and can be stacked or organized to create large composite constructions tailor-made to the project's needs.

Reclaiming Land: A Sustainable Foundation for Development

Land reclamation—creating new land from oceans, riverbeds, or lake beds—is critical for port expansions, industrial development, and defending low-lying areas. Geotubes for erosion manage serve as a indispensable device in this process. Traditionally, rock or concrete seawalls shaped the perimeter of reclamation sites. However, geotextile tube structures provide a faster, regularly greater cost-effective, and material-efficient alternative. They can be deployed to create containment bunds or conserving dikes that outline the reclamation area. Once these permeable tubes are in region and filled, they stabilize the perimeter, permitting for the managed infilling of the unique zone. The tubes themselves can end up a everlasting phase of the reclaimed land's basis or be integrated into the closing slope safety system. Furthermore, the use of regionally dredged fill fabric in the tubes minimizes the want for transporting quarried rock, lowering the project's standard carbon footprint and environmental disturbance. This approach of the use of sediment dewatering luggage on a big scale turns a dredging byproduct—often viewed waste—into a precious building material, closing an ecological loop.

Restoring Nature's Barriers: Dune Rehabilitation and Protection

Coastal dunes are dynamic, herbal obstacles that soak up storm surge energy, defend inland areas, and grant special habitats. When dunes are degraded with the aid of storms or human activity, they lose their shielding capacity. Here, geotubes for erosion manipulate play a restorative role. In dune restoration projects, smaller-diameter geotextile tube constructions are set up seaward of the broken dune or at once as its new core. They act as an immediate, secure sand nucleus, dissipating wave strength and decreasing similarly erosion. Critically, they are designed to work with herbal processes. Wind-blown sand shortly accumulates round and over the tubes, whilst vegetation can be planted at once in the sand that collects on and between them. Over time, the tubes grow to be totally buried and built-in into a revitalized, naturally functioning dune system. The cloth is chosen to final lengthy ample for the dune to re-establish itself earlier than degrading. This utility of sediment dewatering luggage as a foundational template hurries up herbal recovery, supplying immediately safety whilst fostering long-term ecological resilience. It’s a top instance of "working with nature" instead than towards it.

Key Advantages Over Traditional Methods

The developing adoption of geotextile tube structures is pushed by way of a compelling set of benefits:

Adaptability & Speed: They can be fabricated to customized sizes and are fantastically rapid to install the use of nearby fill substances and general pumping equipment.

Cost-Effectiveness: Significant financial savings are frequently realized via decreased cloth transport, decrease labor requirements, and the utilization of in-situ sediments.

Environmental Compatibility: Their soft, permeable nature has much less influence on wave refraction and sediment transport patterns than strong structures. They can be vegetated and come to be section of the landscape, keeping ecological connectivity.

Durability & Strength: Made from strong polymers, modern-day geotextiles provide remarkable resistance to abrasion, puncture, and UV degradation, making sure long-term performance.

Efficiency in Sediment Management: They grant an environment friendly answer for sediment dewatering, turning unstable, liquid slurry into manageable stable cloth for building or containment purposes.

Critical Considerations for Successful Implementation

While powerful, the success of a geotextile tube undertaking hinges on cautious planning and execution. Key concerns include:

Site-Specific Design: Engineering evaluation of wave forces, currents, soil mechanics, and geotextile homes is non-negotiable. A tube designed for a calm estuary will fluctuate vastly from one for an open coast.

Proper Fill Material: The sediment grain dimension have to be like minded with the fabric's pore dimension to make sure fine dewatering and retention. The pumping slurry consistency is additionally crucial.

Expert Installation: Proper anchoring, seam orientation, and filling tactics are necessary to stop failure. Filling ought to be performed in ranges to enable for even sediment dewatering and consolidation.

Monitoring and Maintenance: While low-maintenance, preliminary inspections after principal storm activities make certain integrity. For everlasting structures, protecting with sand or vegetation protects the material from UV exposure.

The Future of Coastal Resilience

The software of geotextile tube science continues to evolve. Innovations in cloth weaving, coating, and recycling are improving sustainability and performance. Research is ongoing into hybrid structures that mix tubes with herbal factors like oyster reefs or mangrove plantings for more advantageous bioengineering. From developing new habitats to defending current shorelines, the strategic use of geotubes for erosion manipulate and as sediment dewatering baggage represents a smart, bendy toolkit for 21st-century coastal engineers and environmental managers.

Conclusion: A Flexible Tool for a Sustainable Coastline

In conclusion, geotextile tubes provide a transformative strategy to constructing resilience in dynamic coastal environments. By harnessing the simplicity of sand and the power of superior textiles, this technological know-how affords an effective, economical, and ecologically touchy technique for each land reclamation and dune restoration. Whether serving as the core of a new business quay or the hidden spine of a restored sandy habitat, these structures show that clever engineering can work in concord with herbal processes. For challenge planners, engineers, and environmental groups looking for demonstrated geotubes for erosion control, the implementation of expertly designed geotextile tube and sediment dewatering bag techniques provides a effective pathway to impervious our shores and reclaim our landscapes for a sustainable future.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province