Why HDPE Geomembrana Is a Must-Have for Landfill Liners (Benefits & Installation Tips)

Landfills are indispensable for managing municipal and industrial waste, however they pose good sized environmental dangers barring suited containment. Leachate—toxic fluid shaped through rainwater mixing with decomposing waste—can seep into soil and groundwater, threatening ingesting water materials and ecosystems. This is the place a reliable geomembrane liner landfill system will become essential. Among all geomembrane options, High-Density Polyethylene (HDPE) stands out as the most relied on solution. Below, we ruin down the unbeatable advantages of hdpe geomembrane liner and share specialist set up guidelines to make sure long-term overall performance for landfill projects.

1. Unmatched Benefits of HDPE Geomembrane Liner for Landfills

HDPE geomembrane is now not simply a famous desire for landfills—it’s a necessity, thanks to three core blessings that tackle the special challenges of waste containment.

1.1 Superior Impermeability: The Core of Geomembrane Liner Landfill Protection

The important intention of any landfill liner is to block leachate, and hdpe geomembrane liner excels here. HDPE has an extraordinarily low permeability charge (typically ≤1×10⁻¹² cm/s), some distance decrease than herbal clay liners or different artificial geomembranes like PVC. This skill even hint quantities of poisonous leachate can't penetrate the liner, stopping soil and groundwater contamination. For geomembrane liner landfill projects, this impermeability isn’t simply a feature—it’s a regulatory requirement in most regions, as it safeguards public fitness and the environment. Unlike clay liners (which crack over time due to agreement or temperature changes), hdpe geomembrane maintains its barrier homes for 20+ years, making sure steady safety in the course of the landfill’s lifecycle.

1.2 Exceptional Durability to Withstand Landfill Harshness

Landfills are unforgiving environments: heavy waste loads, UV exposure, sharp particles (like steel scraps or damaged glass), and intense temperature swings can break inferior liners. HDPE geomembrane liner is engineered to withstand these stressors. It has excessive tensile strength, permitting it to stretch except tearing below compacted waste weight. It’s additionally UV-stabilized, so extended solar publicity won’t purpose brittleness or degradation. Additionally, HDPE is puncture-resistant—when paired with a geotextile cushion layer, it can stand up to sharp objects in waste. For landfill operators, this sturdiness interprets to decrease renovation costs: not like more cost effective geomembranes that want regular repairs, hdpe geomembrane requires minimal upkeep, lowering long-term expenses.

1.3 Chemical Resistance to Handle Toxic Leachate

Landfill leachate is a combine of acids, bases, heavy metals (like lead and mercury), and natural compounds—substances that corrode many liners. HDPE geomembrane is inherently chemically inert, making it best for geomembrane liner landfill applications. It won’t react with leachate components, stopping degradation or holes that compromise the barrier. This resistance is fastidiously tested: producers expose HDPE to frequent landfill contaminants to make sure it retains performance. For industrial landfills (which deal with greater aggressive waste), hdpe geomembrane liner is frequently the solely choice that meets security standards, as it avoids the leachate-induced screw ups frequent with PVC or LDPE liners.

2. HDPE Geomembrane vs. Traditional Liners: Why It’s Better for Geomembrane Liner Landfill

To recognize why hdpe geomembrane liner is a must-have, it’s essential to evaluate it to regular landfill liners—highlighting clear blessings that make HDPE the most useful choice.

2.1 HDPE vs. Clay Liners

Clay liners had been as soon as frequent for landfills however have most important flaws. Clay has greater permeability (1×10⁻⁷ cm/s or more), that means leachate can seep via over time. It’s additionally inclined to cracking: soil settlement, freeze-thaw cycles, or heavy gear can create gaps, ruining the barrier. Installing clay liners is labor-intensive, too—they require specific compaction and moisture control, which delays projects. HDPE geomembrane, via contrast, has 100,000x decrease permeability than clay, is crack-resistant, and installs quickly. For geomembrane liner landfill projects, HDPE eliminates the dangers of clay failure whilst saving time and labor costs.

2.2 HDPE vs. PVC/LDPE Geomembranes

PVC (Polyvinyl Chloride) and LDPE (Low-Density Polyethylene) are more cost-effective than HDPE however lack its durability. PVC depends on plasticizers that leachate can wreck down, making the liner brittle and leaky inside 5–10 years. LDPE has greater permeability and decrease tensile strength, so it tears without difficulty below waste loads. HDPE geomembrane liner avoids these issues: it has no plasticizers, resists leachate corrosion, and is robust ample to take care of heavy landfill use. For geomembrane liner landfill projects, HDPE’s longer lifespan (25+ years) capacity decrease substitute costs, making it a extra low-cost funding than PVC or LDPE.

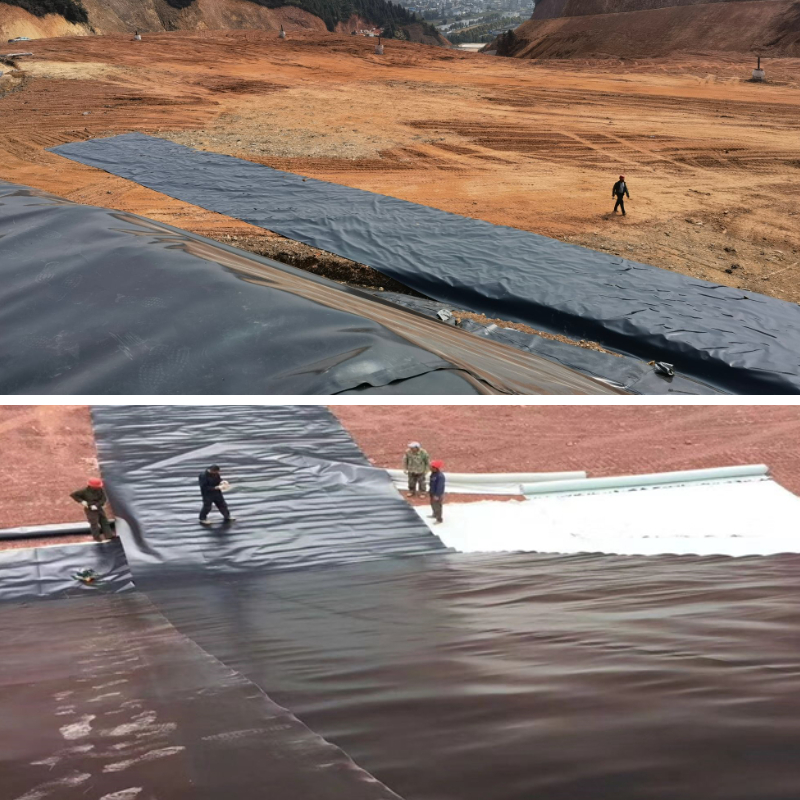

3. Expert Installation Tips for HDPE Geomembrane Liner

Even the best hdpe geomembrane fails if established poorly. Proper set up is key to maximizing its overall performance for geomembrane liner landfill projects. Here are vital steps to follow:

3.1 Prepare the Site Thoroughly

Before laying hdpe geomembrane liner, the landfill base should be smooth, clean, and stable. Remove all sharp particles (rocks, roots, metal) that should puncture the liner. Level uneven terrain with compacted gravel or soil—this prevents the liner from stretching or tearing below waste. Add a geotextile cushion layer underneath HDPE: this greater barrier protects in opposition to punctures and distributes weight evenly. For geomembrane liner landfill sites with excessive groundwater, set up a drainage layer (like gravel) to redirect water away from the liner, decreasing stress that ought to purpose damage.

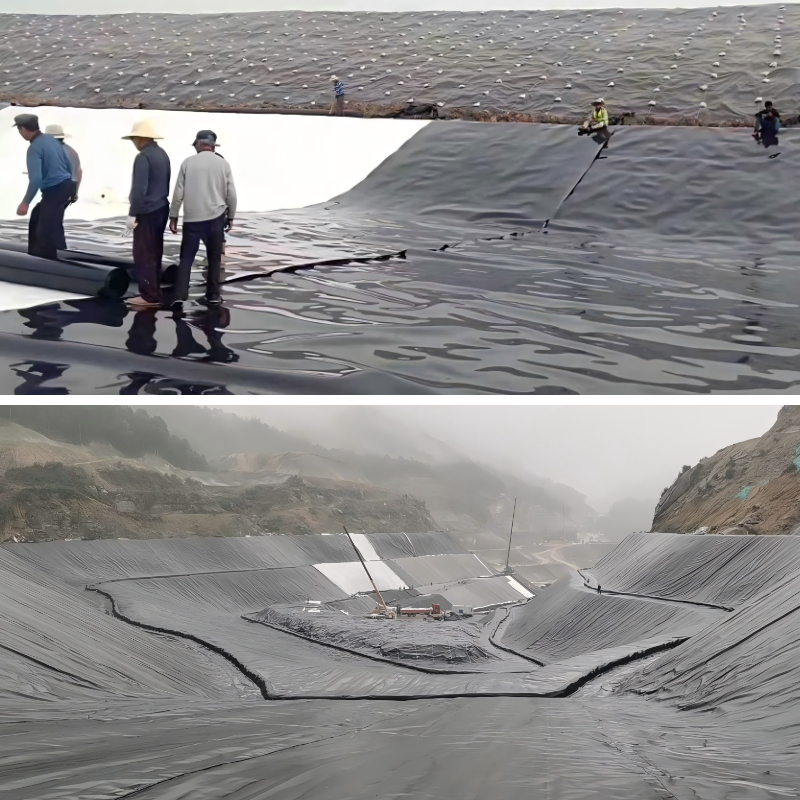

3.2 Master Seam Welding (The Most Critical Step)

Seams are the weakest factors of any geomembrane liner—bad welds lead to leaks. For hdpe geomembrane liner, use warm wedge welding or extrusion welding: these techniques soften HDPE edges together, growing a seam more suitable than the liner itself. Follow these rules:

Keep liner surfaces smooth and dry (moisture weakens welds).

Test each and every one hundred ft of seam with a vacuum take a look at (to take a look at for air gaps) or air stress check (to become aware of leaks).

Hire licensed welders: uncertified work is the #1 motive of HDPE disasters in geomembrane liner landfill projects.

3.3 Conduct Post-Installation Inspections

After installing hdpe geomembrane, don’t omit inspections. Use electrical leak detection (ELD): this science scans the liner for tiny holes (even 0.1mm) that visible exams miss. Inspect seams again—heavy gear all through set up can harm welds. For regulatory compliance, employ a third-party inspector to confirm the liner meets geomembrane liner landfill standards. This step ensures no leaks go undetected, fending off environmental fines or luxurious repairs later.

Conclusion

For geomembrane liner landfill projects, hdpe geomembrane liner is non-negotiable. Its most suitable impermeability blocks leachate, its sturdiness withstands landfill harshness, and it outperforms ordinary liners like clay or PVC. When paired with professional installation—site prep, applicable welding, and inspections—hdpe geomembrane delivers long-term protection, reduces costs, and maintains landfills compliant with environmental regulations.

If you’re planning a geomembrane liner landfill project, make investments in high-quality hdpe geomembrane and associate with skilled installers. This ensures your liner performs as intended, safeguarding the surroundings and your backside line for decades.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province