The Role of Permeability and Moisture Control in Concrete Impregnated Fabric Applications

In construction, repair, and environmental projects, balancing structural integrity with moisture administration is a regular challenge. Excess moisture can weaken materials, reason cracking, or compromise performance, whilst inadequate permeability may additionally entice water and lead to long-term damage.

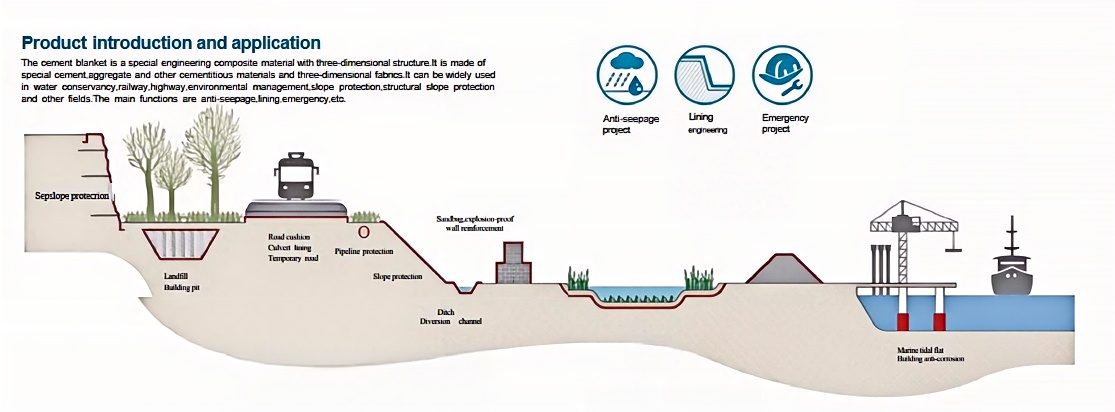

Concrete impregnated fabric—a bendy composite of cloth reinforcement and dry concrete mix—addresses this stability via engineered permeability and unique moisture control. Unlike inflexible concrete or impermeable fabrics, this fabric adapts to moisture conditions, making sure electricity whilst managing water flow. This information explores how permeability and moisture manage outline the overall performance of concrete impregnated fabric, highlighting its function in key purposes and how Flexible Concrete Blanket editions optimize these properties. By perception these dynamics, you’ll see why concrete impregnated cloth is turning into a go-to answer for moisture-sensitive projects.

Understanding Permeability in Concrete Impregnated Fabric

Permeability refers to a material’s capacity to permit fluids (like water) to ignore via its structure. For concrete impregnated fabric, permeability is now not a one-size-fits-all trait—it’s engineered into the material’s design, various via fabric type, concrete mix, and activation method.

The core of the fabric’s permeability lies in its twin structure: a cloth matrix (often glass fiber or polyester) and a dry concrete layer. When activated with water, the concrete hydrates and hardens, however the textile’s weave creates micro-voids and channels inside the hardened matrix. These voids are sized to manage water flow: small ample to forestall immoderate seepage that should weaken the material, however massive ample to permit trapped moisture or extra water to escape. This managed permeability units concrete impregnated material aside from standard concrete, which is regularly impermeable and inclined to cracking underneath moisture pressure.

Moisture Control: The Key to Concrete Impregnated Fabric Performance

Moisture manipulate is twofold for concrete impregnated fabric: first, managing the water wished to prompt the concrete (hydration), and second, regulating moisture publicity in the course of and after installation. Proper moisture manipulate ensures the concrete treatments evenly, develops full strength, and resists degradation from water-related damage.

During activation, Flexible Concrete Blanket—a famous structure of concrete impregnated fabric—simplifies moisture control. The blanket’s material layer acts as a reservoir, protecting water lengthy adequate for the concrete to hydrate totally barring drying out too quickly. This is crucial in dry or windy environments, the place usual concrete mixes may also lose moisture earlier than curing properly. After installation, the fabric’s permeability lets in extra moisture (e.g., from rain or groundwater) to drain away, stopping pooling that should purpose efflorescence, spalling, or structural weakening.

How Permeability and Moisture Control Enhance Applications

The stability of permeability and moisture manage makes concrete impregnated cloth versatile throughout various applications, fixing moisture-related challenges that plague standard materials:

1. Repair and Rehabilitation Projects

In repairing concrete constructions (e.g., bridges, walls, or pipes), moisture trapped under usual restore substances regularly leads to delamination or cracking. Concrete impregnated cloth conforms to broken surfaces and its permeability permits trapped moisture to get away at some stage in and after installation. For example, when repairing a water-damaged wall, the fabric’s micro-voids let moisture evaporate, whilst the hardened concrete varieties a durable, bonded repair. Flexible Concrete Blanket is specially beneficial here, as it can be wrapped round curved surfaces (like pipes) and activated with minimal water, making sure constant moisture manage even in hard-to-reach areas.

2. Slope Stabilization and Erosion Control

Slopes are inclined to moisture-related failure—water infiltration weakens soil, main to landslides or erosion. Concrete impregnated material stabilizes slopes through reinforcing soil whilst managing water flow. Its permeability lets in rainwater to drain thru the cloth into the soil below, decreasing floor runoff and pore water pressure. At the equal time, the hardened concrete layer prevents soil erosion by means of protecting the slope from raindrop impact. In moist climates, this stability is critical: the cloth doesn’t entice water, which would weigh down the slope, however additionally doesn’t permit immoderate drainage that should strip soil particles.

3. Waterproofing and Containment

While concrete impregnated material is permeable, it can be engineered for selective waterproofing. By adjusting the concrete combine (e.g., including waterproofing admixtures) or fabric weave, producers create variations that face up to water penetration in one route whilst permitting vapor to escape. This is best for functions like basement partitions or preserving structures, the place stopping liquid water ingress is key however permitting vapor diffusion prevents mildew growth. Unlike inflexible waterproofing membranes, which can crack, the bendy cloth adapts to minor structural motion whilst preserving its moisture barrier properties.

4. Temporary and Emergency Structures

In emergency response (e.g., flood barriers, brief shelters) or brief construction, Flexible Concrete Blanket excels at fast deployment and moisture resilience. The blanket is light-weight and compact when dry, activating shortly with water to structure a hardened, permeable structure. For flood barriers, its permeability approves water to seep thru slowly, decreasing hydrostatic stress whilst the concrete layer offers structural strength. Temporary shelters built with concrete impregnated material continue to be dry inner via permitting interior moisture (e.g., condensation) to escape, enhancing livability besides compromising climate resistance.

Engineering Permeability and Moisture Control: Key Design Factors

Manufacturers tailor concrete impregnated fabric’s permeability and moisture manage thru various format choices:

1. Textile Matrix Design

The textile’s weave (woven vs. non-woven) and fiber kind have an impact on permeability. Woven textiles create uniform, managed voids, whilst non-woven textiles provide greater porosity for quicker drainage. Glass fiber textiles, for example, are frequently used in high-moisture functions for their resistance to water injury and capacity to preserve weave integrity at some stage in hydration.

2. Concrete Mix Composition

The dry concrete combine consists of components to regulate moisture control: retarders sluggish hydration in warm weather, making sure the concrete doesn’t set too quickly; accelerators pace curing in bloodless conditions. Waterproofing admixtures limit permeability for containment applications, whilst porous aggregates extend permeability for drainage-focused projects.

3. Activation Method

Moisture manage starts offevolved with activation: Flexible Concrete Blanket can be activated with spray, immersion, or sprinkling, permitting specific manage over water volume. Manufacturers furnish hydration tips (e.g., water-to-fabric ratio) to make sure the concrete treatments evenly, balancing electricity and permeability.

Why Concrete Impregnated Fabric Outperforms Traditional Materials in Moisture Management

Compared to inflexible concrete, impermeable membranes, or artificial fabrics, concrete impregnated material affords special moisture administration advantages:

Adaptive Permeability: It adjusts to moisture conditions, draining extra water whilst protecting adequate for desirable curing.

Flexibility with Strength: Unlike inflexible concrete, it bends barring cracking, keeping moisture manipulate even as constructions shift.

Rapid, Controlled Activation: Flexible Concrete Blanket simplifies moisture manipulate at some point of installation, decreasing the threat of under- or over-hydration.

Mold and Mildew Resistance: By permitting vapor escape, it prevents moisture buildup that leads to organic growth—a frequent problem with impermeable materials.

Conclusion: Moisture Management as a Core Strength of Concrete Impregnated Fabric

Permeability and moisture manipulate are no longer simply brought advantages of concrete impregnated fabric—they are core sketch concepts that define its performance. By balancing managed water waft with particular hydration management, this fabric solves moisture-related challenges that usual options can’t address.

Whether used for repairs, slope stabilization, waterproofing, or emergencies, concrete impregnated fabric—especially Flexible Concrete Blanket—delivers strength, flexibility, and moisture resilience. As initiatives an increasing number of face unpredictable climate and moisture-related risks, this material’s capability to manipulate water whilst keeping structural integrity makes it an quintessential device for engineers, contractors, and emergency responders. Invest in concrete impregnated fabric, and you’ll construct options that stand up to moisture—not simply today, however for years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province