How to Cut and Shape Concrete Impregnated Fabric for Custom Projects

Concrete impregnated fabric, frequently acknowledged through names like cement blanket or cement cloth, has revolutionized customized building and DIY projects. Its flexibility when dry and inflexible electricity when activated with water make it perfect for growing special shapes and structures. This information walks you thru the method of reducing and shaping this versatile fabric to carry your customized tasks to life.

Understanding Concrete Impregnated Fabric Basics

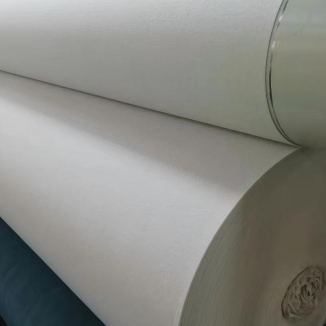

Concrete impregnated cloth is a fabric cloth infused with a different concrete mixture. Unlike common concrete, which requires mixing and molding, this material arrives prepared to use—dry, lightweight, and handy to handle. When uncovered to water, the concrete inside the material activates, hardening into a durable, stable shape over time.

Cement blanket and cement fabric are genuinely versions of the same concept, designed to mix the electricity of concrete with the flexibility of fabric. This special residences make them ideal for customized initiatives the place popular concrete’s stress would be a limitation, such as curved walls, ornamental elements, or small-scale structural additions.

Tools Needed for Cutting and Shaping

Before starting, accumulate the proper equipment to make certain easy cuts and specific shapes. For reducing concrete impregnated fabric, a sharp utility knife or heavy-duty scissors works best—avoid stupid blades, as they can fray the cloth and disrupt the concrete infusion. A straightedge or ruler helps create straight lines, whilst a marker or chalk can mark reduce traces barring destructive the material.

For shaping, you’ll want helps or molds to preserve the material in vicinity as it dries. These can be transient constructions made from wood, foam, or even sand—anything that can stand up to the fabric’s weight as soon as moist and preserve the favored shape. Clamps or weights might also additionally be beneficial to invulnerable the material to the mildew for the duration of the hardening process.

Step-by-Step Cutting Process

Prepare the Workspace: Lay the concrete impregnated material flat on a clean, dry surface. Ensure there’s adequate house to maneuver the cloth and equipment besides inflicting wrinkles or folds, which can have an effect on the last shape.

Mark the Cut Lines: Use a marker or chalk to define the preferred dimensions. For complicated shapes, trace a template onto the fabric—this ensures accuracy, mainly for customized designs like arches or ornamental panels.

Make the Cut: Hold the cloth taut with one hand to forestall shifting. Use a sharp utility knife or scissors to comply with the marked lines. For straight cuts, run the knife alongside the side of a straightedge to keep away from uneven edges. Take your time—slow, constant cuts end result in cleaner edges that bond higher if portions want to be joined later.

Trim Frayed Edges: After cutting, test for free threads or frayed areas. Trim these gently with scissors to make certain the material lays flat and the concrete hardens evenly.

Shaping Techniques for Custom Projects

Shaping concrete impregnated material is the place its versatility in reality shines. Here’s how to gain extraordinary forms:

Curved Structures: For curves, drape the dry cloth over a curved mildew (like a half-cylinder of foam or a bent wood frame). Ensure the material suits snugly except stretching too tight, as overstretching can skinny the fabric and weaken the last structure. Mist the cloth gently with water to make it greater pliable earlier than shaping—this helps it conform to the mold.

Angled or Sloped Designs: Use inflexible supports, such as timber planks set at the favored angle, to prop up the fabric. Secure the edges with clamps or weights to maintain the slope in place. When activating with water, begin from the backside and work upward to forestall sagging.

3D Shapes: For 3-dimensional tasks like small planters or ornamental sculptures, wrap the material round a mildew that suits the preferred shape. Overlap edges barely if needed, as the moist concrete will bond them collectively as it hardens. Smooth out any wrinkles to make sure a uniform finish.

Activating and Setting the Fabric

Once reduce and shaped, it’s time to prompt the concrete. Mist the cloth evenly with water the usage of a spray bottle—avoid soaking it, as extra water can dilute the concrete combination and weaken the closing product. Alternatively, dip smaller portions in a bucket of water for a few seconds, then squeeze out extra moisture earlier than shaping.

After activation, depart the cloth in its mildew undisturbed. The hardening method normally takes 24–48 hours, relying on temperature and humidity. During this time, preserve the vicinity dry and keep away from transferring the fabric, as this can reason cracks or misshaping. Once entirely hardened, put off the mould cautiously to expose your customized structure.

Tips for Success with Cement Blanket and Cement Cloth

Work Quickly: Once activated with water, the material starts to harden, so have your mould prepared earlier than wetting. Plan your cuts and shapes in increase to keep away from rushing.

Test Small Pieces First: If working on a giant project, exercise reducing and shaping with a small piece of cement fabric to get a experience for the material’s flexibility and how it responds to water.

Seal for Extra Protection: For out of doors tasks or these uncovered to moisture, practice a concrete sealer after the cloth has entirely cured. This enhances sturdiness and prevents water harm over time.

Avoid Overlapping Too Much: While overlapping edges can bond, immoderate layers can create susceptible spots. Keep overlaps to a minimal (1–2 inches) and press them firmly collectively when wet.

Common Custom Projects Using Concrete Impregnated Fabric

Concrete impregnated cloth excels in a vary of customized applications:

Garden Edging: Cut strips of cement blanket to create curved or straight backyard borders that combination with landscaping.

Decorative Wall Panels: Shape the material into textured panels for accent walls, including depth and industrial appeal to interiors.

Small Shelving Units: Mold the material into L-shaped brackets or easy shelves, best for light-weight storage.

Planters and Bird Baths: Craft unique, weather-resistant containers with the aid of shaping the cloth over spherical or irregular molds.

Conclusion

Concrete impregnated fabric—whether referred to as cement blanket, cement cloth, or with the aid of its technical name—offers countless probabilities for customized projects. By following these steps for cutting, shaping, and activating, you can radically change this bendy cloth into durable, one-of-a-kind structures. Its ease of use, blended with its strength, makes it a favored amongst DIY fanatics and specialists alike. Whether you’re constructing backyard features, indoors decor, or small structural elements, this versatile material simplifies the method of growing customized designs that stand the check of time.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province