HDPE Geomembrane vs. Clay Liners: Cost, Durability & Environmental Impact Compared

When it comes to containment options for landfills, wastewater remedy plants, reservoirs, or mining sites, deciding on the proper liner cloth is critical. Two of the most broadly used picks are HDPE geomembrane and clay liners. Each has special houses that make them appropriate for particular applications, however appreciation their variations in cost, durability, environmental impact, and set up is key to making an knowledgeable decision. In this guide, we’ll ruin down these vital elements to assist you decide which liner device aligns with your project’s wishes and goals.

1. Cost Comparison: HDPE Geomembrane vs. Clay Liners

Cost is frequently the main consideration for task managers, and each HDPE geomembrane and clay liners have wonderful price constructions that lengthen past preliminary fabric expenses. Let’s wreck down the direct and oblique charges related with each.

1.1 Initial Material & Installation Costs

Clay liners normally have decrease upfront fabric costs, as clay is a naturally happening cloth that is frequently sourced locally. This reduces transportation expenses, a vast element in large-scale projects. However, clay liners require large website preparation, consisting of excavation, compaction, and grading to gain the required density (usually 95% compaction). The labor and gear expenses for this education can add up quickly, particularly if the web site has bad soil prerequisites that require extra amendments.

HDPE geomembrane, on the different hand, has greater preliminary fabric prices due to the manufacturing manner of high-density polyethylene. However, geomembrane set up is usually extra efficient. HDPE geomembrane sheets are light-weight and can be rapidly deployed, welded, and sealed through a educated crew. While the cloth itself is extra highly-priced per rectangular foot, the decreased labor and web site instruction time frequently stability out the upfront costs, specially for tasks with giant floor areas. It’s vital to notice that geomembrane set up great immediately influences long-term costs, so hiring skilled specialists is quintessential to keep away from highly-priced repairs later.

1.2 Long-Term Maintenance & Replacement Costs

Clay liners require ongoing preservation to forestall cracks and breaches. Over time, clay can dry out, shrink, or be broken via root intrusion or animal activity. Repairs frequently involve excavating the broken area, re-compacting clay, and regrading—processes that are labor-intensive and costly. Additionally, clay liners have a shorter lifespan (typically 20-30 years) in contrast to HDPE geomembrane, that means alternative may additionally be crucial sooner, including to the whole lifecycle cost.

HDPE geomembrane has minimal long-term preservation requirements. The cloth is resistant to UV radiation, chemical degradation, and root intrusion, lowering the want for time-honored repairs. With applicable geomembrane set up and periodic inspections, HDPE liners can final 50 years or more. While occasional repairs (such as welding fixes for small tears) may additionally be needed, these are typically much less luxurious and time-consuming than clay liner repairs. The longer lifespan of HDPE geomembrane regularly makes it a greater reasonably priced choice over the project’s lifetime.

2. Durability: Which Liner Stands the Test of Time?

Durability is a non-negotiable thing for containment liners, as breaches can lead to environmental contamination, regulatory fines, and high-priced cleanup efforts. The sturdiness of HDPE geomembrane and clay liners varies notably based totally on cloth houses and resistance to exterior stressors.

2.1 Resistance to Chemicals & Contaminants

Clay liners count number on their low permeability to forestall the migration of contaminants. However, clay is prone to chemical degradation when uncovered to acidic or natural wastes (such as landfill leachate or industrial effluents). These chemical compounds can smash down the clay’s structure, growing its permeability and growing pathways for contaminants to seep into the groundwater. Clay liners are excellent acceptable for non-chemical applications, such as freshwater reservoirs.

HDPE geomembrane is enormously resistant to a extensive vary of chemicals, which includes acids, bases, solvents, and natural compounds. This makes it an perfect preference for harsh environments like landfills, mining tailings ponds, and industrial wastewater cure facilities. The inert nature of HDPE ensures that the liner continues its structural integrity even when uncovered to aggressive contaminants, lowering the chance of breaches. Additionally, HDPE geomembrane can be manufactured with extra components to decorate its chemical resistance for unique applications.

2.2 Physical Strength & Resistance to Damage

Clay liners are enormously fragile in contrast to HDPE geomembrane. They are susceptible to cracking if the underlying soil settles or shifts, and they can be without problems broken by means of development equipment, root intrusion, or animal burrowing. Once a crack forms, it can shortly expand, main to big leaks. Clay liners additionally have low tensile strength, that means they can't stand up to lots stretching except breaking.

HDPE geomembrane has high-quality bodily strength, together with excessive tensile electricity and puncture resistance. The fabric is flexible, permitting it to adapt to minor soil settlements barring cracking. HDPE geomembrane sheets are welded collectively the use of warmness fusion, growing a seamless barrier that is as robust as the cloth itself. This seamless development eliminates susceptible factors that are frequent in clay liners. When exact installed, HDPE geomembrane can face up to the weight of overlying materials, development traffic, and different bodily stressors.

3. Environmental Impact: Sustainability & Ecological Considerations

In today’s regulatory landscape, the environmental have an effect on of development substances is a pinnacle priority. Both HDPE geomembrane and clay liners have environmental professionals and cons that ought to be evaluated.

3.1 Material Sourcing & Carbon Footprint

Clay liners are made from herbal clay, a renewable resource. Sourcing neighborhood clay reduces transportation-related carbon emissions, which is a substantial environmental benefit. However, the excavation and compaction technique for clay liners requires heavy machinery, which consumes fossil fuels and emits greenhouse gases. Additionally, large-scale clay extraction can disrupt neighborhood ecosystems, inclusive of soil erosion and habitat destruction.

HDPE geomembrane is a artificial fabric made from petroleum, a non-renewable resource. The manufacturing system entails refining petroleum and extruding it into sheets, which generates carbon emissions. However, many HDPE geomembrane producers now provide recycled HDPE options, which minimize reliance on virgin petroleum and decrease the carbon footprint. Additionally, the light-weight nature of HDPE geomembrane reduces transportation charges and emissions in contrast to transporting massive volumes of clay. The longer lifespan of HDPE geomembrane additionally capability fewer replacements, lowering the normal environmental influence over time.

3.2 Containment Effectiveness & Environmental Protection

The main environmental characteristic of a liner is to forestall infection of groundwater and soil. Clay liners have a greater threat of leaks due to their permeability and susceptibility to damage, which can lead to environmental harm. Even small breaches can end result in the migration of contaminants, affecting nearby water sources and wildlife.

HDPE geomembrane’s low permeability (far decrease than clay liners) and seamless development make it a extra fine barrier towards contamination. This most advantageous containment protects groundwater, soil, and ecosystems from hazardous substances. Additionally, HDPE geomembrane is inert and does no longer leach any poisonous chemical substances into the environment, in contrast to some clay amendments that may additionally incorporate heavy metals. For tasks in environmentally touchy areas, HDPE geomembrane is frequently the desired preference to meet strict regulatory standards.

4. Installation Complexity: Time, Labor & Expertise

The complexity of set up at once influences mission timelines, labor costs, and the universal success of the liner system. HDPE geomembrane and clay liners have awesome set up necessities that require one of a kind stages of information and resources.

4.1 Clay Liner Installation

Clay liner set up is a labor-intensive and time-consuming process. It starts with website excavation to take away topsoil and any unsuitable materials. The clay is then sourced, transported to the site, and spread in skinny layers (typically 6-12 inches thick). Each layer ought to be compacted to the required density the use of heavy rollers, and the floor need to be smoothed to stop gaps. The installation technique is exceedingly established on climate conditions—clay can't be mounted when it is too moist or too dry, as this impacts compaction. Additionally, clay liners require strict nice manipulate to make sure uniform density and permeability, which provides to the complexity and cost.

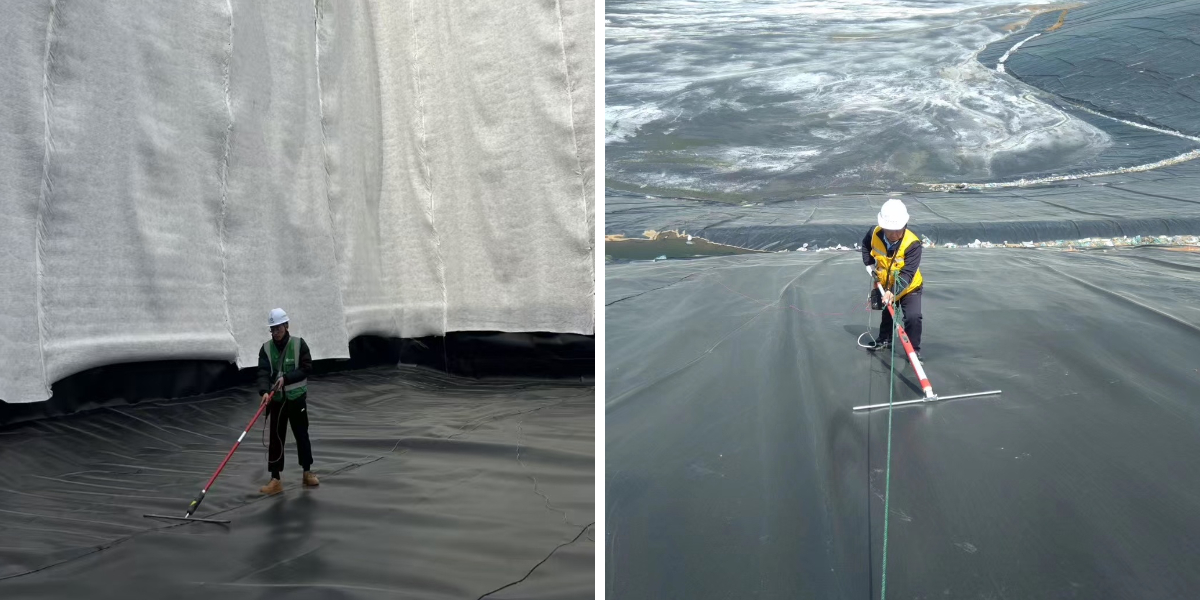

4.2 HDPE Geomembrane Installation

While geomembrane set up requires specialised expertise, it is typically quicker and much less labor-intensive than clay liner installation. The manner starts offevolved with web page preparation, which includes grading and doing away with sharp objects that may want to puncture the geomembrane. HDPE geomembrane sheets are then unrolled and located to limit seams. The sheets are welded collectively the usage of warmness fusion equipment, which creates a strong, seamless bond. Quality manipulate for geomembrane set up consists of trying out welds the use of techniques such as air stress trying out or vacuum container checking out to make certain no leaks. HDPE geomembrane can be established in most climate stipulations (except excessive bloodless or heat), permitting initiatives to remain on schedule. The effectivity of geomembrane set up makes it perfect for tasks with tight timelines.

Conclusion: Choosing the Right Liner for Your Project

Both HDPE geomembrane and clay liners have their area in containment applications, however their suitability relies upon on your project’s particular needs. Clay liners can also be a low-priced alternative for small-scale, non-chemical purposes with neighborhood clay sources. However, HDPE geomembrane provides most appropriate durability, chemical resistance, environmental protection, and long-term fee financial savings for most large-scale or harsh surroundings projects. When thinking about geomembrane installation, hiring an skilled contractor is vital to make sure the liner gadget performs as intended.

If you’re searching for a reliable, long-lasting containment answer that meets strict environmental standards, HDPE geomembrane is probable the quality choice. Its most beneficial performance, minimal maintenance, and lengthy lifespan make it a rewarding funding for initiatives that require most safety in opposition to contamination.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province