Cement Blanket for Mine Site Rehabilitation: Stabilizing Soil & Preventing Runoff

Mine website online rehabilitation is a fundamental environmental and regulatory requirement for mining operations worldwide. Unregulated mine web sites face extreme troubles such as soil erosion, unstable slopes, and contaminated runoff, which pose threats to neighborhood ecosystems, water sources, and human settlements. In current years, cement blanket (also regarded as cement impregnated material or cement canvas) has emerged as a game-changing answer for mine web site rehabilitation. This progressive cloth combines the electricity of concrete with the flexibility of fabric, providing efficient, durable, and low-cost options for soil stabilization and runoff prevention. Below, we discover the key advantages and functions of cement blanket in mine website rehabilitation, assisting mining experts and environmental engineers make knowledgeable choices for their projects.

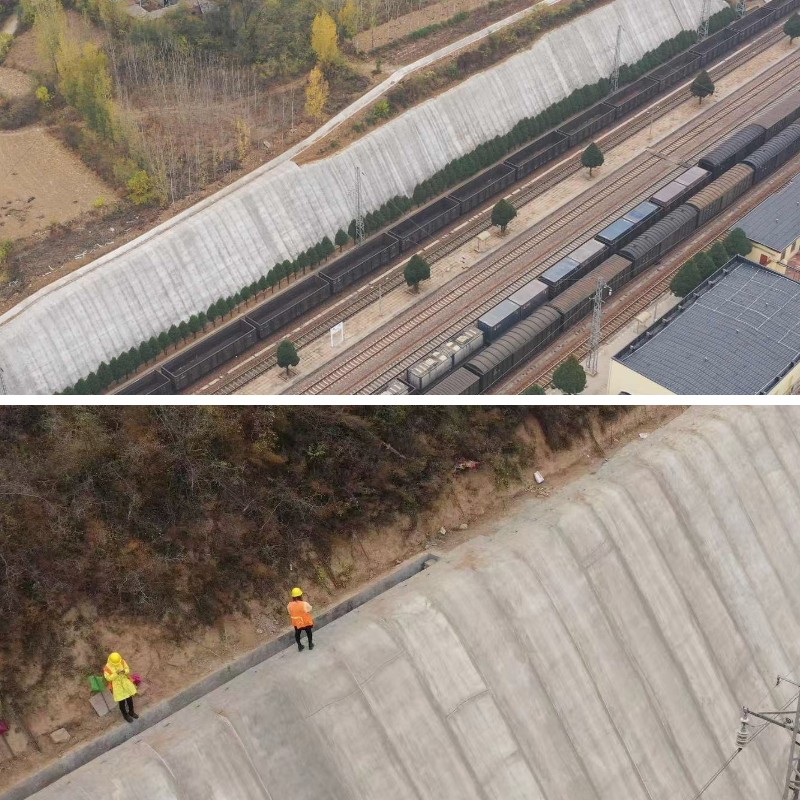

1. Why Cement Blanket Is Ideal for Mine Site Rehabilitation: Core Performance Advantages

Mine websites are characterised with the aid of harsh, unstable environments—exposed soil, steep slopes, and regular publicity to wind, rain, and chemical contaminants.Cement blanket is uniquely engineered to tackle these challenges, with overall performance benefits that outperform common rehabilitation substances like concrete slabs or gravel. Its core strengths lie in its durability, flexibility, and resistance to environmental stressors.

1.1 Exceptional Soil Stabilization Strength

Once activated with water, cement impregnated cloth hardens into a rigid, high-strength shape that bonds tightly with the underlying soil. This creates a stable, erosion-resistant layer that prevents soil particle movement—even on steep mine slopes (up to 60 degrees) the place common substances are inclined to sliding or cracking. The cured cement blanket has a compressive electricity of up to forty MPa, related to traditional concrete, making sure long-term steadiness for rehabilitated mine areas.

1.2 Resistance to Contaminants and Harsh Weather

Mine website runoff regularly incorporates heavy metals, acids, and different contaminants that can degrade usual materials. Cement canvas is inherently resistant to chemical corrosion, as the cement matrix varieties a barrier in opposition to poisonous substances, stopping them from leaching into the soil and groundwater. Additionally, it withstands severe climate conditions—from heavy rainfall and flooding to severe daylight and freeze-thaw cycles—without degrading, making sure regular overall performance in numerous mining environments.

1.3 Flexibility for Irregular Terrain

Unlike inflexible concrete, cement blanket is bendy in its unactivated state, permitting it to conform to the irregular terrain of mine web sites (e.g., uneven slopes, depressions, and rocky surfaces). This flexibility eliminates the want for large web site grading, lowering development time and minimizing similarly disturbance to the fragile mine ecosystem. Once cured, it continues structural integrity whilst adapting to minor floor movements, lowering the chance of cracks and failures.

2. Key Applications in Mine Site Rehabilitation: Stabilization & Runoff Control

In mine web site rehabilitation, cement blanket serves two fundamental purposes: stabilizing unstable soil (e.g., slopes, tailings dams) and stopping contaminated runoff. Its versatility makes it appropriate for a couple of indispensable applications, every addressing precise environmental risks.

2.1 Slope Stabilization in Abandoned Mine Areas

Abandoned mine slopes are amongst the most unstable areas, with a excessive threat of landslides and soil erosion. Cement impregnated material affords a dependable answer with the aid of overlaying uncovered slopes and bonding with the soil to create a cohesive, secure mass. For example, in open-pit mine rehabilitation, cement blanket is laid over steep waste rock piles to stop rock falls and soil loss. Its speedy curing time (typically 24-48 hours) lets in for fast stabilization, decreasing the window of environmental risk. Additionally, the cloth can be seeded with native vegetation thru pre-formed holes, merchandising ecological restoration whilst retaining structural stability.

2.2 Tailings Dam Rehabilitation & Leak Prevention

Tailings dams are a foremost supply of environmental threat in mining, as leaks can launch contaminated water into surrounding ecosystems. Cement canvas is used to line tailings dams and impoundments, growing an impermeable barrier that prevents seepage of heavy metals and poisonous chemicals. Unlike usual liners (e.g., geomembranes), cement blanket is puncture-resistant and bonds with the dam structure, lowering the hazard of leaks due to floor motion or damage. It additionally strengthens the dam’s embankments, enhancing ordinary balance and lowering the danger of catastrophic failures.

2.3 Contaminated Runoff Control & Drainage Systems

Mine web page runoff consists of sediments, heavy metals, and acids that can pollute close by water sources. Cement blanket is used to assemble drainage channels, culverts, and sediment traps that redirect and filter runoff. The smooth, difficult floor of cured cement blanket prevents channel erosion, making sure the drainage machine stays practical long-term. Additionally, when used in sediment traps, it slows the waft of water, permitting sediments and contaminants to settle earlier than the water is discharged, lowering environmental impact. In some cases, cement blanket channels are lined with a skinny layer of activated carbon to similarly filter poisonous substances.

3. Construction Advantages: Saving Time, Labor, and Environmental Disturbance

Mine web page rehabilitation tasks frequently face tight timelines and strict environmental constraints. Cement blanket provides enormous development benefits over regular materials, making it a greater environment friendly and sustainable desire for mine operators.

3.1 Quick Installation & Curing

Cement impregnated cloth is furnished in rolls (typically 2-4 meters broad and 10-20 meters long), which can be effortlessly transported to far flung mine websites and unrolled immediately onto the work area. Installation requires solely a small group and primary tools (e.g., water pumps, rollers), putting off the want for heavy equipment like concrete mixers or graders. Once installed, the cloth healing procedures quickly—achieving 80% of its closing energy inside 24 hours and full power inside 7 days—allowing for quicker mission completion and formerly ecological restoration.

3.2 Reduced Labor and Material Costs

Compared to common concrete, cement canvas reduces labor charges by using up to 50%, as it requires fewer employees and much less specialised skills. It additionally minimizes fabric waste, as the rolls can be reduce to suit the actual dimensions of the project, decreasing extra cloth usage. Additionally, the removing of on-site concrete mixing reduces transportation prices (no want to haul sand, gravel, and cement to far off mine sites) and lowers carbon emissions, aligning with sustainable mining practices.

3.3 Minimal Environmental Disturbance

Traditional mine rehabilitation strategies (e.g., grading, concrete pouring) can similarly disturb the fragile mine ecosystem, unfavourable ultimate vegetation and soil structure. Cement blanket set up requires minimal website online preparation—only casting off massive particles and leveling minor irregularities—reducing soil compaction and vegetation loss. Its flexibility additionally lets in it to work round present native plants, advertising ecological coexistence. Furthermore, the cloth is non-toxic as soon as cured, posing no danger to nearby flora and fauna or plant life.

4. Cost-Effectiveness: Long-Term Value for Mine Rehabilitation Projects

While the upfront fee of cement blanket might also be barely greater than some typical materials, its long-term cost-effectiveness makes it a sensible funding for mine website online rehabilitation. The material’s durability, low renovation requirements, and capability to stop steeply-priced environmental failures offset the preliminary expense.

4.1 Lower Maintenance and Replacement Costs

Cement impregnated cloth has a lifespan of 20-30 years when top installed, appreciably longer than normal substances like gravel (5-10 years) or geomembranes (10-15 years). It requires no everyday maintenance—no repainting, patching, or resealing—reducing ongoing operational costs. In contrast, standard substances regularly want regularly occurring repairs due to erosion, cracking, or degradation, including to the complete venture fee over time.

4.2 Avoiding Costly Environmental Penalties

Mining operations face strict regulatory penalties for environmental violations, such as soil erosion, contaminated runoff, or landslides. Cement canvas reduces the threat of these violations via offering dependable soil stabilization and runoff control, assisting mine operators keep away from fines and prison fees. Additionally, it helps organizations meet sustainability goals and enhance their environmental reputation, which can lead to higher neighborhood members of the family and get entry to to new mining permits.

4.3 Return on Investment (ROI) for Long-Term Projects

For long-term mine rehabilitation projects, the ROI of cement blanket is compelling. A find out about of deserted mine slope rehabilitation tasks discovered that the use of cement blanket decreased complete task charges by using 30% over 10 years in contrast to concrete slabs, due to decrease installation, maintenance, and alternative costs. The material’s capacity to speed up ecological restoration additionally permits mine websites to be repurposed for different makes use of (e.g., agriculture, recreation) sooner, developing extra financial value.

Final Thoughts: Cement Blanket as a Sustainable Solution for Mine Rehabilitation

Cement blanket (or cement impregnated fabric, cement canvas) is a versatile, durable, and most economical answer for mine website online rehabilitation, addressing two of the most urgent challenges: soil stabilization and contaminated runoff prevention. Its special mixture of flexibility, strength, and environmental resistance makes it best for the harsh prerequisites of mine sites, whilst its rapid set up and low preservation necessities shop time and labor. For mining authorities and environmental engineers looking for a sustainable way to meet regulatory necessities and fix broken ecosystems, cement blanket is a optimum desire over typical materials.

If you’re planning a mine website rehabilitation assignment and favor to analyze extra about how cement blanket can be tailor-made to your particular needs—whether for slope stabilization, tailings dam rehabilitation, or runoff control—contact our group of experts today. We’ll grant personalized solutions, technical support, and aggressive prices to assist you acquire successful, sustainable mine rehabilitation.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province