Understanding Geomembrane Thickness (Mil & Gauge) and Why It Matters for Your Project

Introduction: Thickness – The Critical Determinant of Performance

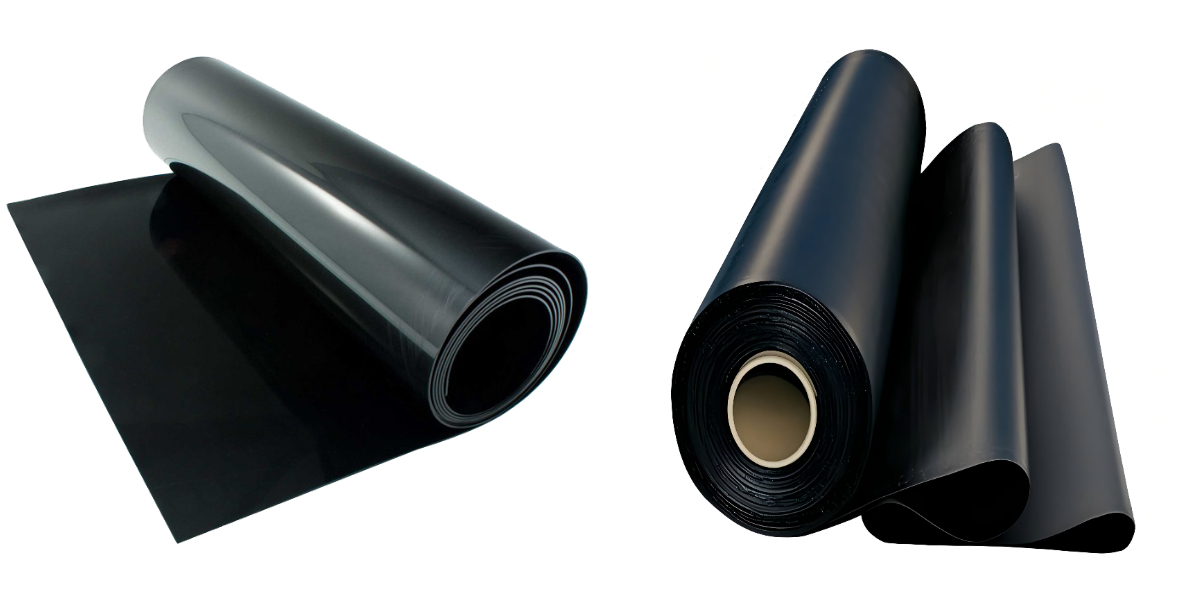

In the world of geomembranes, one specification stands as the fundamental indicator of durability, strength, and long-term performance: thickness. Choosing the right thickness is now not a mere clerical decision; it is a vital engineering desire that dictates whether or not your containment device will be successful for many years or fail prematurely. Whether you are deciding on a bendy pvc geomembrane for a canal lining or a strong polyethylene liner for a landfill, perception the devices of measurement—primarily mil and gauge—and their realistic implications is paramount. This information demystifies these phrases and explains why thickness is arguably the most necessary issue in your specification, without delay impacting the entirety from puncture resistance to set up survivability, mainly in annoying functions like geomembrane in street construction.

Decoding the Units: What Are Mil and Gauge?

Geomembrane thickness is expressed in two common, and frequently confused, units:

1. Mil (a thousandth of an inch)

Definition: 1 mil = 1/1000 of an inch (0.001 inch).

Industry Standard: This is the predominant and favored unit for most geomembrane materials, specially polyethylenes like HDPE and ldpe geomembrane. It is unambiguous and approves for specific specification and measurement.

Example: A 60-mil HDPE geomembrane is 0.060 inches thick.

2. Gauge

Important: "Gauge" is no longer a standardized unit of linear measurement. Its fee in inches or mils varies relying on the fabric and enterprise context.

Common Usage: In some areas and for positive substances like pvc geomembrane, "gauge" is used informally, frequently the place 1 gauge is approximated as 1 mil. However, this is an approximation and can lead to errors. Always affirm the specific mil thickness when "gauge" is used.

Key Conversion: For sensible functions in geomembranes, and solely after verification, it is frequently assumed: 1 mil ≈ 1 gauge. The most secure exercise is to specify and procure the usage of mil (e.g., forty mil PVC) to make certain absolute clarity.

Why Thickness Is Non-Negotiable: The Performance Link

Thickness immediately correlates with a suite of mechanical homes that outline a geomembrane's potential to operate its containment feature over time.

1. Puncture and Tear Resistance

This is the most direct relationship. A thicker geomembrane affords increased resistance to penetration from sharp objects in the subgrade (rocks, roots) or from overlying substances (drainage aggregate, waste). For instance, a 100-mil ldpe geomembrane will provide considerably greater puncture resistance than a 30-mil model of the equal material. This is fundamental all through and after installation.

2. Tensile Strength and Stress Crack Resistance

While tensile electricity is additionally a feature of polymer quality, extended cross-sectional vicinity (thickness) contributes to the average load-bearing ability of the membrane. Thicker liners are higher in a position to stand up to localized stresses and long-term anxiety besides yielding or creating stress cracks, a integral consideration for uncovered liners or these on slopes.

3. Durability and Longevity

Thickness acts as a reservoir of material. It offers a increased margin towards the inevitable consequences of environmental stress cracking, oxidative degradation, and minor set up abrasions. A thicker liner genuinely has greater fabric to lose earlier than its integrity is compromised, extending its engineered carrier life. This is why important landfill liners and caps are usually distinctive at 60-mil or 80-mil HDPE, now not 20-mil.

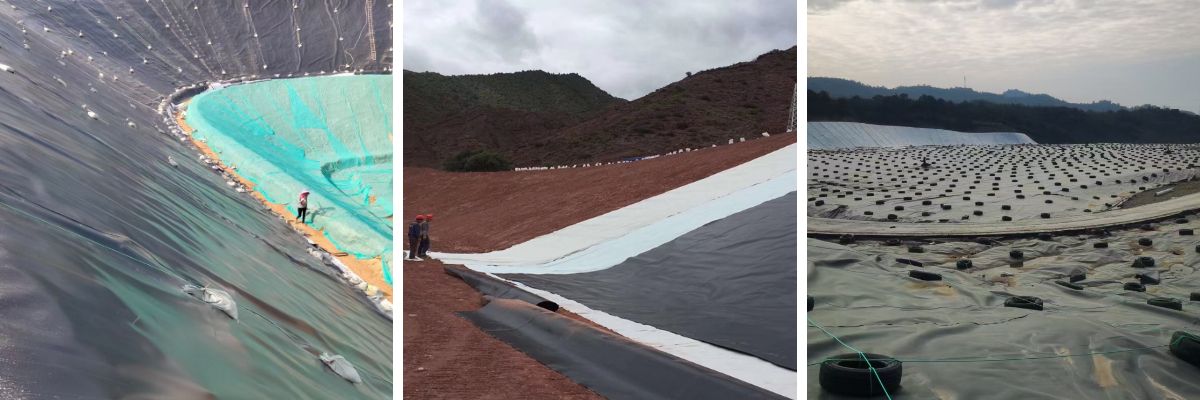

4. Survivability During Installation

The set up manner is the most abusive section of a geomembrane's life. Thicker substances are much less susceptible to harm from foot traffic, equipment, and wind uplift at some stage in deployment and seaming. This robustness interprets to fewer repairs, much less building delay, and a higher-quality last installation.

Material-Specific Thickness Considerations

PVC Geomembrane: Commonly accessible in a vary from 20 to forty mils (often known as 20-40 gauge). Its inherent flexibility permits for fine overall performance at these thicknesses in purposes like pond liners, canal linings, and secondary containment. A 30-mil pvc geomembrane is a versatile, mid-range preference for many water containment projects.

LDPE/LLDPE Geomembrane: These bendy polyethylenes are regularly used in the 20 to eighty mil range. A 40-mil ldpe geomembrane may be chosen for a ornamental pond or landfill cap the place conformity is key, whilst a thicker 60-mil model would be targeted for a greater stressful software with a heavier overburden.

HDPE Geomembrane: The workhorse for essential containment, HDPE is normally special from 30 to a hundred mils, with 60, 80, and a hundred mil being popular for landfills, mining, and massive reservoirs. Its stiffness requires cautious subgrade preparation, mainly at greater thicknesses.

Thickness in Context: The Example of Road Construction

The use of a geomembrane in street building (as a moisture barrier or separation layer) flawlessly illustrates the thickness-performance trade-off. Here, the liner is positioned between the subgrade and the mixture base direction and subjected to excessive static and dynamic loads.

A 20-mil liner would possibly be tempting for low-cost, brief get admission to roads.

However, a 40-mil or thicker geomembrane (often HDPE or a bolstered composite) is nearly usually endorsed for everlasting roads. The purpose is survivability: the thicker membrane can stand up to the puncture forces from sharp, compacted combination and the big strain from development tools and repeated visitors except tearing. The preliminary greater cloth price is offset by using stopping street failure, base direction contamination, and high priced reconstruction—a clear case the place specifying ample thickness is an funding in the whole project's longevity.

How to Select the Right Thickness for Your Project

Choosing thickness is a feature of threat assessment, now not simply budget. Consider these factors:

Subgrade Conditions: Rocky, uneven subgrades demand a thicker, greater puncture-resistant liner.

Overburden Stress: Will the liner be underneath two toes of drainage stone or 50 ft of strong waste? Higher overburden pressures require increased thickness.

Chemical Exposure: More aggressive leachates or fluids may also warrant a thicker liner as a protection aspect towards long-term chemical attack.

Project Design Life: A 50-year landfill requires a unique specification than a 5-year transient building laydown area.

Industry Standards & Regulations: Always seek advice from applicable suggestions (e.g., GRI GM13 for HDPE) and neighborhood regulatory minimums, which frequently prescribe baseline thicknesses for unique applications.

Conclusion: Specifying with Confidence

Geomembrane thickness, measured precisely in mils, is the cornerstone of a dependable containment system. It is the single most seen proxy for durability, strength, and standard quality. While a thinner, less expensive liner might also appear economically fascinating upfront, it always will increase the hazard of set up damage, untimely failure, and catastrophic environmental liability.

Understanding that a 40-mil pvc geomembrane gives one-of-a-kind skills than a 40-mil ldpe geomembrane, and that the use of a sufficiently thick geomembrane in street development is quintessential for success, empowers you to make knowledgeable decisions. Always prioritize the thickness required for the precise web page stipulations and undertaking dangers over preliminary unit cost. In the realm of geosynthetics, opting for ample thickness is the most easy way to make certain your liner is now not simply a sheet of plastic, however a high-performance, engineered barrier constructed to last. Consult with skilled engineers and producers to decide the gold standard thickness—it is the most essential range on your specification sheet.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province