How Composite Geomembranes Work: The Synergy of Geotextile and Impermeable Barrier

Composite geomembranes characterize a widespread development in cutting-edge geosynthetic engineering, presenting foremost overall performance with the aid of combining the strengths of two awesome materials. This article explores the modern plan and working standards of these engineered systems, explaining how the synergy between a protecting geotextile issue and a bendy impermeable barrier creates a sturdy answer for containment and protection. Understanding this interplay is key to appreciating their massive use in initiatives ranging from irrigation canals to landfill liners, the place sturdiness and reliability are paramount.

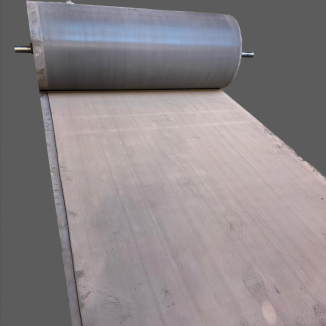

The Fundamental Design: A Layered Solution

At its core, a composite geo-membrane is a manufactured, multi-layered sheet. It is systematically engineered by using bonding a long lasting geotextile—typically a non-woven, felt-like material—to a bendy impermeable membrane, most frequently one based totally on High-Density Polyethylene (HDPE). This aggregate is no longer only a lamination of two sheets; it is a deliberate integration the place every layer is chosen for its precise houses and the blended overall performance exceeds the sum of its parts. The geotextile acts as a protecting cushion and drainage medium, whilst the impermeable layer, such as an HDPE composite geomembrane, offers the quintessential hydraulic barrier. This layout is what makes a composite geomembrane especially wonderful in stressful environmental applications, which include large-scale water administration infrastructure.

The Role of the Impermeable Barrier: The Primary Line of Defense

The coronary heart of any composite geomembrane is its impermeable layer. This element is accountable for growing a reliable, long-term barrier towards fluid migration. HDPE composite geomembrane is a commonplace desire for this layer due to its high-quality chemical resistance, very low permeability, and excessive tensile strength. The HDPE sheet is actually tightly closed to water and most leachates, stopping seepage from ponds, landfills, or irrigation channels into the surrounding soil and groundwater. Its most important feature is containment, whether or not it is retaining treasured water in an Irrigation Project Composite Geomembrane set up or stopping contaminated fluids from escaping a waste facility. The material's inherent sturdiness ensures this barrier characteristic persists for decades, even beneath challenging subsurface conditions.

The Role of the Geotextile: Protection, Drainage, and Stability

While the impermeable barrier handles containment, the geotextile element performs various quintessential assisting roles. First and foremost, it affords mechanical protection. During set up and at some point of its provider life, the underlying geomembrane can be subjected to puncture forces from sharp rocks, gravel, or uneven subgrade. The geotextile layer absorbs these stresses, distributing localized hundreds and stopping them from compromising the integrity of the impermeable barrier beneath. Furthermore, in many composite geo-membrane applications, the geotextile enables drainage and fuel venting. It can act as a conduit, permitting water or gases that may accumulate at the interface to tour laterally, relieving doubtlessly negative hydrostatic pressure. This characteristic is necessary for keeping the balance of overlaying systems and stopping uplift.

The Synergistic Effect: How the Layers Work Together

The authentic engineering genius of a composite geomembrane lies in the synergistic interplay between its layers. The geotextile and the impermeable membrane create a gadget the place every factor mitigates the weaknesses of the other. The sturdy, puncture-resistant geotextile shields the extra vulnerable, slick polymeric membrane from direct abrasion and puncture. Conversely, the tough, seamless HDPE composite geomembrane gives a non-stop barrier that the geotextile by myself may want to in no way achieve. This synergy enhances set up survivability—the product can be rolled out over rougher subgrades than a standalone geomembrane. It additionally improves long-term overall performance through managing interface stresses and pore pressures. In an Irrigation Project Composite Geomembrane liner, this synergy ensures that water is retained successfully whilst the liner device stays intact towards the canal's subsoil and backfill.

Application in Practice: The Irrigation Project Example

Consider a large-scale agricultural irrigation canal. The important venture is to deliver water over lengthy distances with minimal loss due to seepage. A standalone geomembrane may want to be punctured by means of the subgrade, whilst a geotextile on my own would no longer forestall seepage. A Composite Geomembrane solves each issues. During the set up of this Irrigation Project Composite Geomembrane, the product is rolled immediately onto the organized canal bed. The geotextile aspect is regularly positioned downward, cushioning the impermeable HDPE composite geomembrane from sharp protrusions in the soil. As the canal is filled, the geotextile additionally helps control any minor water vapor transmission or soil gas, stopping bubbles or wrinkles. The end result is a extraordinarily efficient, long lasting lining that conserves water, prevents soil salinization, and requires much less protection than normal clay or concrete linings. This sensible utility flawlessly illustrates the composite advantage.

Advantages and Long-Term Benefits

The use of a composite geo-membrane can provide a host of advantages. It affords gold standard puncture and tear resistance in contrast to single-layer geomembranes, main to a decrease chance of set up harm and long-term failure. The built-in safety layer regularly reduces the want for expensive, cautiously graded soil cushion layers, simplifying development and decreasing challenge costs. The device additionally offers increased interface friction with adjoining soils, improving slope steadiness in containment structures. For asset owners, this interprets into a greater reliable, longer-lasting containment answer with a decrease whole lifecycle cost. Whether the undertaking is a reservoir, a waste containment cell, or a ornamental pond, the composite format ensures performance.

Conclusion

In summary, composite geomembranes work by using harnessing the complementary homes of a sturdy geotextile and a high-performance impermeable barrier like HDPE composite geomembrane. The geotextile presents protection, drainage, and stress distribution, whilst the polymeric membrane gives an impeccable seal towards fluids. Their synergy creates a geosynthetic product that is higher than the sum of its parts—one that is simpler to install, greater resistant to area challenges, and sooner or later extra reliable. For engineers designing vital containment infrastructure, from an Irrigation Project Composite Geomembrane device to environmental safety barriers, perception this synergy is fundamental for specifying a answer that ensures challenge integrity, sustainability, and success for a long time to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province