Concrete Impregnated Fabric in Repair and Strengthening: Retrofitting Bridges and Buildings

Aging infrastructure—from highways bridges to historical buildings—faces inevitable wear: cracks, spalling concrete, and decreased load-bearing potential threaten security and longevity. Traditional retrofitting methods, like concrete jacketing or metal reinforcement, are costly, time-consuming, and frequently disruptive to day by day operations. Concrete impregnated material has emerged as a transformative solution, imparting a lightweight, flexible, and high-strength choice for restore and strengthening. Beyond structural fixes, this cloth is reshaping concrete material constructing and concrete material constructing practices, enabling environment friendly retrofits that hold unique constructions whilst boosting performance. This information explores how concrete impregnated material revolutionizes bridge and constructing retrofitting, its key benefits, real-world applications, and why it’s turning into a staple in infrastructure renewal.

The Challenge of Aging Infrastructure: Why Traditional Repairs Fall Short

Bridges and constructions deteriorate over time due to environmental stress (freeze-thaw cycles, moisture, UV radiation), heavy loads, and cloth fatigue. Cracks in concrete permit water and chemical compounds to penetrate, accelerating corrosion of metal reinforcement. Traditional restore strategies tackle these problems however come with drawbacks: concrete jacketing provides substantial weight, requiring extra structural support; metal plates are inclined to corrosion and require big installation; and demolition-rebuild processes are luxurious and wasteful.

For historical concrete material constructing buildings or busy bridges, these strategies are regularly impractical—they disrupt traffic, injury architectural details, or lengthen venture timelines for months. Concrete impregnated cloth solves these ache factors by way of adhering immediately to current surfaces, including energy besides immoderate weight, and enabling speedy installation. Its flexibility lets in it to conform to curved or irregular shapes, making it perfect for retrofitting complicated structures.

How Concrete Impregnated Fabric Works for Repair and Strengthening

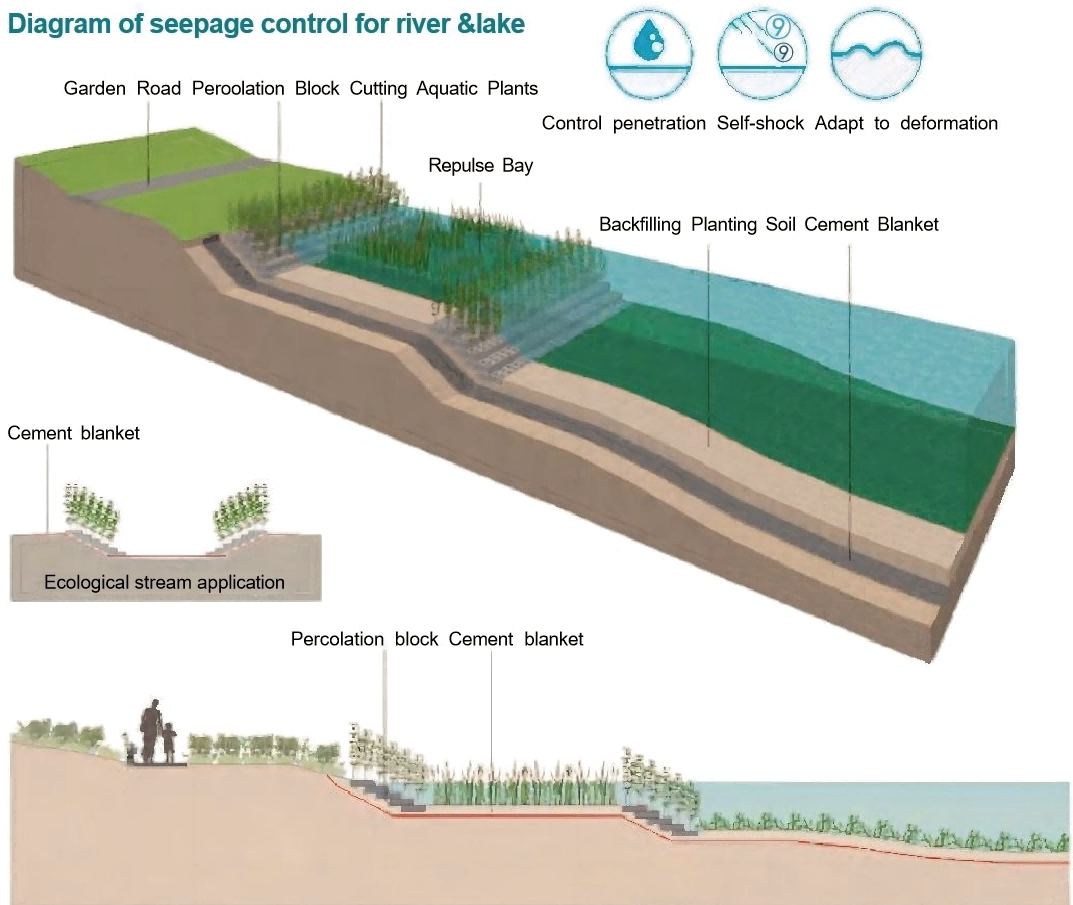

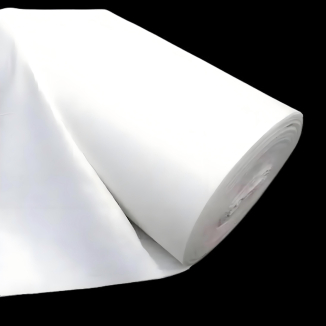

Concrete impregnated cloth is a composite cloth consisting of a cloth reinforcement matrix (typically glass fiber or carbon fiber) infused with a dry concrete combine (Portland cement, aggregates, and additives). When activated with water, the concrete hydrates and hardens, forming a dense, long lasting layer bonded to the current structure.

The material matrix offers tensile strength, addressing the weak spot of undeniable concrete (which is sturdy in compression however vulnerable in tension). When utilized to cracked or weakened concrete, the material bridges gaps, distributes loads, and prevents in addition crack propagation. For strengthening, a couple of layers can be utilized to expand load-bearing capacity—each layer including power besides huge thickness. This makes it perfect for cement blanket constructing retrofits the place house or weight is limited, such as bridge girders or constructing columns.

Key Benefits of Concrete Impregnated Fabric in Retrofitting

Concrete impregnated cloth provides special blessings that make it ideal to normal retrofitting methods:

1. Lightweight and Minimal Weight Gain

Unlike concrete jacketing, which provides lots of kilos per rectangular foot, concrete impregnated cloth is lightweight. Even with more than one layers, it provides minimal weight to the structure, getting rid of the want for steeply-priced changes to aid systems. For bridges, this capability no discount in load potential due to restore materials, and for concrete material constructing retrofits, it preserves the unique structural balance.

2. Rapid Installation and Minimal Disruption

Concrete impregnated material installs in a fraction of the time of regular methods. It arrives in rolls, is reduce to measurement on-site, activated with water, and applied at once to organized surfaces (cleaned and repaired cracks). A traditional bridge beam retrofit can be performed in days, in contrast to weeks for metal plating. For buildings, this skill much less downtime for occupants—retrofits can frequently be performed throughout off-hours except disrupting enterprise or residential use.

3. Superior Adhesion and Durability

When activated, concrete impregnated cloth varieties a sturdy chemical bond with present concrete, growing a monolithic shape that acts as a single unit. This adhesion prevents delamination (separation of restore cloth from the unique structure), a frequent failure factor in usual jacketing. The hardened cloth is additionally resistant to moisture, UV radiation, and chemical corrosion, making sure long-term overall performance in harsh environments. For coastal bridges or cement blanket constructing in industrial areas, this sturdiness interprets to fewer upkeep cycles and prolonged provider life.

4. Flexibility for Complex Shapes

Bridges and historical concrete material constructing regularly characteristic curved, irregular, or ornate surfaces that are challenging to restore with inflexible substances like metal or poured concrete. Concrete impregnated cloth is bendy when wet, conforming to arches, columns, and ornamental small print except compromising strength. This flexibility makes it best for retrofitting historical structures, the place maintaining architectural integrity is as vital as structural performance.

Real-World Applications: Concrete Impregnated Fabric in Action

Across the globe, concrete impregnated cloth has confirmed its fee in numerous retrofitting projects, from busy dual carriageway bridges to centuries-old buildings:

1. Bridge Girder Strengthening

A important motorway bridge in a mid-sized town confronted decreased load potential due to corrosion of metal reinforcement in its girders. Traditional metal plating would have required closing the bridge for weeks and including heavy assist structures. Instead, engineers used concrete impregnated fabric: they cleaned the girders, utilized three layers of the fabric, and activated it with water. The task used to be performed in forty eight hours, with the bridge reopening to site visitors immediately. Post-retrofit checks confirmed a 30% enlarge in load-bearing capacity, assembly present day security requirements barring disrupting each day commutes.

2. Historic cement blanket Building Restoration

A Twenties concrete material building—a landmark theater with ornate concrete facade details—suffered from spalling concrete and cracks due to many years of freeze-thaw cycles. Demolition used to be no longer an option, and usual concrete patching would have included the theater’s ornamental elements. Contractors used concrete impregnated cloth reduce to healthy the facade’s elaborate shapes. The cloth was once utilized to broken areas, activated, and painted to suit the authentic color. The result: the theater’s historical persona used to be preserved, and the facade’s structural integrity was once restored, with the cloth forming a shielding barrier in opposition to future moisture damage.

3. Building Column Repair

An workplace constructing in a seismic area had weakened concrete columns that couldn’t face up to plausible earthquakes. Jacketing the columns with common concrete would have decreased ground area and required huge construction. Engineers wrapped the columns in concrete impregnated fabric, developing a thin, sturdy reinforcement layer. The fabric’s tensile electricity better the columns’ capability to withstand lateral forces for the duration of seismic events, and the set up was once carried out all through weekends with no disruption to workplace workers. The assignment additionally value 40% much less than common jacketing.

4. Concrete Fabric Building Retrofit for Sustainability

A present day cement blanket constructing used for warehouse area wanted increased thermal effectivity and structural reinforcement. Concrete impregnated material was once utilized to the indoors walls: the fabric’s porous shape allowed for higher insulation, decreasing the building’s strength consumption through 25%. The cloth bolstered the partitions in opposition to wind loads, making the warehouse extra resilient to extreme weather. This twin benefit—structural reinforcement and sustainability—made the retrofit a low cost preference for the building’s owners.

Why Concrete Impregnated Fabric Outperforms Alternatives in Retrofitting

When in contrast to usual retrofitting materials, concrete impregnated cloth stands out for its special mixture of benefits:

Cost Efficiency: It eliminates the want for heavy equipment, great labor, and lengthy mission timelines, reducing ordinary expenses by using 20–50% in contrast to metal plating or concrete jacketing.

Compatibility: It bonds seamlessly with present concrete, wood, and even masonry, making it versatile for exclusive shape types—from concrete material constructing to steel-reinforced bridges.

Sustainability: The fabric makes use of much less cement than standard concrete repairs, decreasing carbon emissions. It additionally minimizes waste, as it’s reduce to measurement on-site and requires no demolition of present structures.

Long-Term Performance: Its resistance to moisture, corrosion, and UV radiation ensures that retrofits final for decades, lowering the want for everyday protection or re-repairs.

Conclusion: The Future of Infrastructure Retrofitting

Concrete impregnated material is redefining how we restore and enhance getting old infrastructure. Its light-weight design, speedy installation, and capacity to retain architectural integrity make it an perfect answer for bridges, historical concrete material building, and modern-day cement blanket constructing alike. As cities and communities face the mission of updating infrastructure barring disrupting every day existence or breaking budgets, this cloth gives a practical, efficient, and sustainable choice to usual methods.

Whether you’re retrofitting a busy motorway bridge, restoring a ancient landmark, or strengthening a industrial building, concrete impregnated material grants consequences that meet each structural desires and challenge constraints. It’s now not simply a restore material—it’s a device for constructing extra resilient, durable, and timeless infrastructure. As the demand for smarter retrofitting options grows, concrete impregnated material will proceed to lead the way in infrastructure renewal.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province