Application of Shandong Chuangwei Geomembranes in a Guangdong Landfill

Project Background Due to years of operation, the anti - seepage measures of the Shaoguan landfill in Guangdong have failed, resulting in the leakage of landfill leachate, which pollutes the surrounding soil, groundwater, and rivers. The spread of odor has also severely affected the lives of local residents. The local government decided to upgrade and renovate the landfill, with the application of geomembranes being a crucial part.

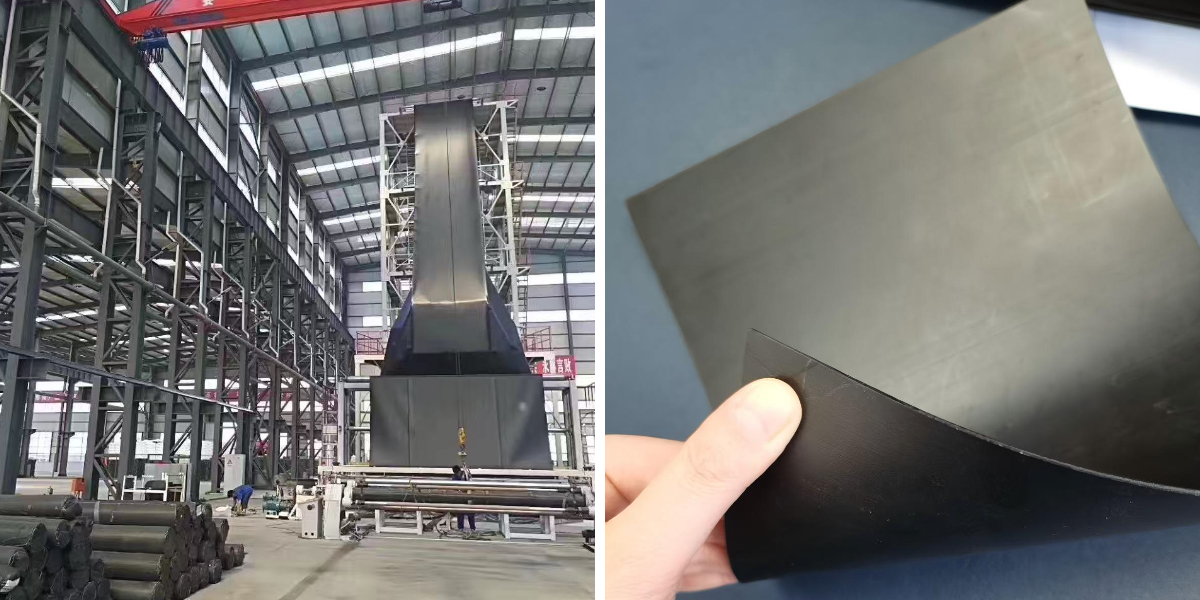

Selection and Construction of Geomembranes High - density polyethylene (HDPE) geomembranes were selected. A 3.0mm smooth geomembrane was used for vertical anti - seepage, and a 1.5mm double - rough geomembrane was used for horizontal anti - seepage. During construction, the site was first cleared of debris and leveled. For vertical anti - seepage, a groove was dug with a grooving machine, and bentonite slurry was used for hole protection. The groove was dug 2m below the impervious layer, with a width of 80cm. After laying the smooth geomembrane, it was connected with a special locking buckle and a rubber waterstop strip. For horizontal anti - seepage, the double - rough geomembrane was cut, spliced, and hot - melt welded, and then promptly inspected and covered with a protective layer.

Advantages of Geomembranes in the Project HDPE geomembranes have an extremely low coefficient of permeability, with anti - seepage effects far exceeding those of traditional materials. They are highly resistant to chemical corrosion, enabling them to adapt to the complex environment of landfill leachate. Their excellent tensile properties allow them to withstand the deformation of landfills. In addition, the construction is lightweight, fast, and does not require large - scale equipment. The project duration was 90 days ahead of schedule, reducing costs.

Project Achievements and Significance After the project was implemented, the problems of leachate leakage and odor were resolved, and the surrounding soil and water environment was improved, bringing significant ecological benefits. At the same time, potential economic losses were reduced, the lifespan of the landfill was extended, and land and construction costs were saved. This case provides valuable experience in material selection, construction technology, and quality control for similar projects, making it highly applicable for wider promotion.