Eco-Friendly Concrete Canvas

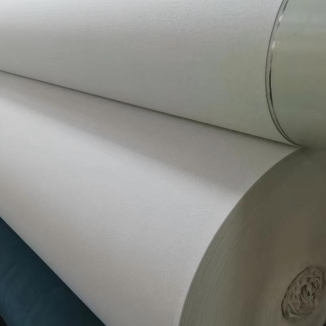

Product Introduction: It is an innovative composite material that combines the flexibility of textiles with the sturdiness of cement, capable of being quickly laid and hardened into a durable concrete layer.

Environmental Protection and Energy Saving: It reduces material waste, and carbon emissions are reduced by more than 90% compared to traditional processes.

Durability: Resistant to freeze-thaw, corrosion, wear, scouring, seawater, and sewage corrosion. It is also resistant to ultraviolet aging, with a service life of up to 50 years.

High Construction Efficiency: No professional equipment is required, and it can be laid by a single person. The speed is 10 times faster than traditional concrete. It features fast forming and is provided in rolls or bulk, facilitating transportation, loading/unloading, and installation.

Strong Flexibility: It can be cut to adapt to complex terrains and even used for vertical suspension.

Product Name: Composite Fiber Concrete Blanket

Eco-Friendly Concrete Canvas are an innovative composite material that combines the flexibility of textiles with the durability of cement, capable of being rapidly deployed and hardening into a robust concrete layer.

Application Areas

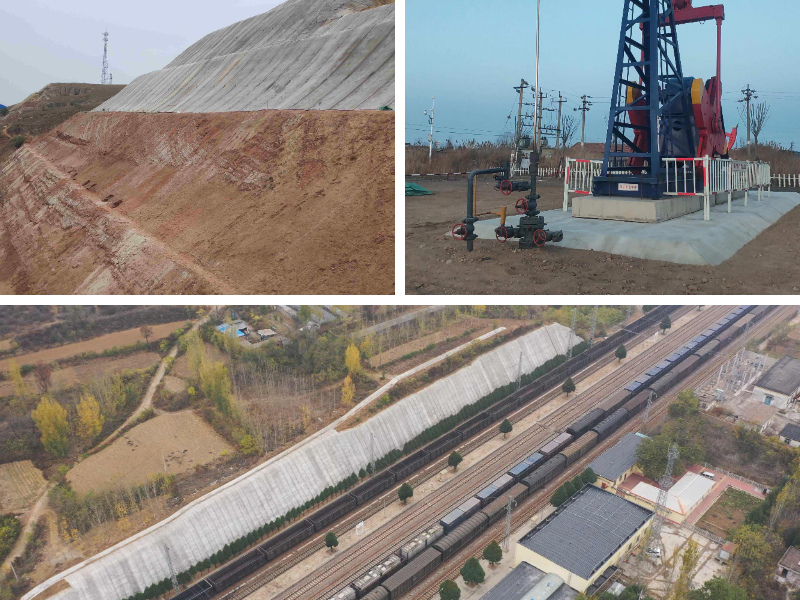

1. Irrigation and Agricultural Engineering - Canal Seepage Prevention: Replaces traditional concrete lining to reduce leakage, suitable for irrigation channels and drainage ditches. - Water Storage Tanks/Water Cellars: Quickly constructs low-cost water storage facilities in arid regions to address agricultural water challenges. - Riverbank Protection: Prevents water erosion, safeguards riverbank soil, and is eco-friendly with convenient construction.

2. Transportation Infrastructure - Slope Protection: Reinforces highway and railway slopes to prevent rain erosion and landslides (can be laid on steep curved surfaces). - Temporary Roads: Provides temporary road surfaces for heavy vehicles in mining and forestry areas, with a load-bearing capacity exceeding 50 tons. - Tunnel Lining: Serves as an initial support layer to quickly seal rock faces and prevent collapses (requires use with anchor rods).

3. Industrial and Municipal Engineering - Factory Flooring: Corrosion-resistant and seepage-proof workshop floors for special environments like chemical plants and slaughterhouses. - Pipeline Wrapping: Anti-corrosion protective layers for underground pipelines to avoid soil acid-base erosion. - Landfill Sites: Acts as a seepage-proof liner to prevent pollutant leakage, offering better puncture resistance than traditional HDPE membranes.

4. Ecological Restoration and Environmental Projects - Mine Greening: Covers exposed mine pits to solidify surface soil and provide a foundation for vegetation restoration. - Desert Sand Stabilization: Lays grid-like concrete blankets to fix mobile sand dunes and assist in afforestation. - Coastal Protection: Replaces traditional rock revetments to reduce ecological damage and prevent tidal erosion.

5. Construction and Landscape Engineering - Temporary Building Foundations: Hardens ground for temporary venues (e.g., exhibitions, events) and can be quickly dismantled and recycled. - Special-shaped Structures: Enables rapid formation of landscape features like sculpture bases and curved flower beds. - Roof Waterproofing: Lightweight seepage-proof layers for roofs with steep slopes or complex shapes.

6. Construction in Special Environments - High-cold Regions: Can harden with water at -30°C (with antifreeze added), solving winter construction challenges for traditional concrete. - Confined Spaces: Enables rapid lining in restricted areas like metro shafts and underground pipe galleries without large equipment. - Marine Environments: Saline-alkali-resistant models are used for repairing dock fenders and breakwaters, resisting seawater corrosion.

7. Emergency Relief and Temporary Projects - Flood Control: Rapidly lays temporary dams and blocks breaches (e.g., river bursts, landslides), forming flood barriers within 2 hours. - Disaster Relief: Builds temporary roads and hardens shelter grounds after earthquakes or typhoons to ensure rescue passage. - Emergency Repairs: Strengthens bridge foundations and rapidly repairs collapsed road sections to avoid traffic interruptions.

8. Military and Security Engineering - Field Fortifications: Quickly constructs shelters, command post floors, or blast walls, hardening within 1 hour to resist light weapon attacks. - Border Facilities: Lays patrol roads or foundations in complex border terrains, adapting to plateaus, swamps, etc. - Anti-terror Barriers: Installs temporary concrete isolation belts to block vehicle impacts, allowing flexible deployment.

| Surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

| length (M) | 10--50 | / | |||

| width (M) | 1--3 | / | |||

| thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

| Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

| Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

| Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

| Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

| Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

| Fire protecting performance | B1 | GB 8624-2012 | |||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

| Copper (total copper) (mg/L) | ≤100 | ||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||

| Cadmium (total) (mg/L) | ≤1 | ||||

| Lead (total lead) (mg/L) | ≤5 | ||||

| Total chromium (mg/L) | ≤15 | ||||

| Nickel (total nickel) | ≤5 | ||||

| Arsenic (total) | ≤5 | ||||

Product Advantages The core advantages of Concrete Canvas lie in rapid construction, flexible adaptability, environmental sustainability, and multi-functionality, summarized as follows:

1. Extremely High Construction Efficiency - Ready-to-Lay: Hardens after watering, reaching usable strength within 24 hours—over 10 times faster than traditional concrete (7-28 days of curing). - No Complex Equipment: Operable by a single person, eliminating mixing, pouring, and vibration steps, ideal for remote areas without power or machinery. - All-Weather Operation: Unaffected by harsh weather (rain, snow, low temperatures), enabling rapid response to emergency projects (e.g., flood control).

2. Flexibility and Adaptability - Cuttable & Bendable: Can be shaped for slopes, ditches, special-shaped structures, or vertical applications. - Lightweight Transportation: Weighs only 15-25 kg/m² (depending on thickness), with roll-up design for easy vehicle or manual transport. - Seamless Formation: Creates continuous concrete layers without joints, eliminating leakage risks (e.g., in water conservancy projects).

3. Environmental Sustainability - Reduced Waste: Precise cutting minimizes cement use, avoiding over-pouring and waste common in traditional concrete. - Low Carbon Emission: Emissions are ≤50 kg/m³ CO₂—92% lower than traditional concrete (no heavy machinery or long-distance transport). - Longevity: Resistant to freeze-thaw and corrosion, with a 50-year lifespan reducing maintenance and resource consumption.

4. Diverse Application Scenarios - Rapid Emergency Response: Deploys temporary roads, flood walls, or shelters during disasters (e.g., earthquakes, floods). - Low-Cost Infrastructure: Suitable for remote-area roads and canal reinforcement, cutting labor and logistics costs. - Special Environment Solutions: Addresses steep slopes, confined spaces, and other challenges beyond traditional concrete.

5. Economic Benefits - Lower Total Cost: Despite higher material costs (¥200-500/m²), overall expenses are 30-50% lower due to reduced equipment, labor, and curing costs. - Shorter Project Timelines: Drastically reduces delays, minimizing indirect losses from traffic disruptions or downtime.

6. Superior Technical Performance

- High Strength: Compressive strength of 20-50 MPa (C20-C50 equivalent), with tensile strength 10 times that of traditional concrete.

- Waterproof & Seepage-Proof: Surface waterproof coating + dense structure ideal for water tanks and drainage systems.

- Fire & High-Temperature Resistance: Some models withstand 1,200°C, suitable for fire safety and industrial applications.