Concrete Impregnated Canvas

1.Convenient construction:No need for on-site mixing, it solidifies with watering and can be manually laid. It hardens in a few hours, greatly reducing the construction period.

2.Stable performance:The compressive strength reaches 20-30MPa, with impermeability and crack resistance, stable performance at -30 ℃ to 60 ℃, and strong durability.

3.Cost economy:Low material loss, fast construction, labor saving, less maintenance, and better long-term costs.

4.Widely applicable:It can be efficiently applied in multiple scenarios such as water conservancy, roads, municipal engineering, emergency engineering, etc.

5.Environmental protection and safety:Low carbon emissions in production, no dust or noise during construction, and no pollution to the environment.

Product Introduction

1.Basic attributes

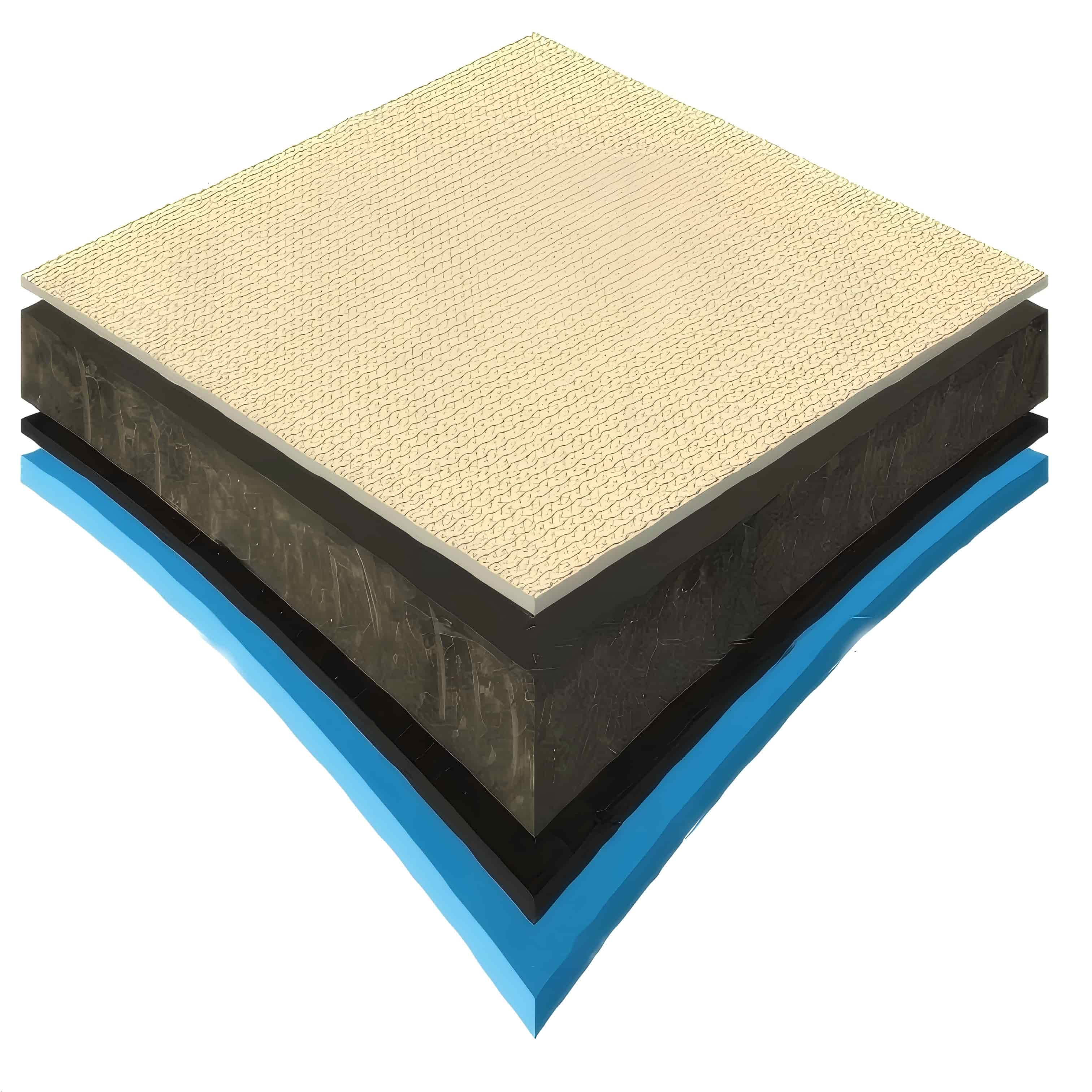

Concrete Impregnated Canvas is a new type of building material that combines cement powder with specially made textile fibers. It looks like a thick cloth, weighs about 15-30kg/㎡, can be stored and transported in rolls, and can be cut into different sizes according to needs. Its core components are cement and fiber, which are compounded through special processes, retaining the strength characteristics of cement while possessing the flexibility of fiber materials.

2.Core functions

Structural protection: After solidification, it forms a sturdy overall structure that can be used for anti-seepage, reinforcement, and lining in scenarios such as channels, dams, and roads, to resist water flow impact, external crushing, etc.

Rapid construction: Curing can be completed by watering, quickly forming a strong structure that meets the rapid construction needs of emergency repairs and short-term projects.

Environmental adaptation: able to maintain stable performance under various climatic conditions, providing lasting structural support and protection for different scenarios.

3.Main features

Convenient and efficient: No need for on-site mixing of cement, manual laying is possible, fast curing speed, greatly saving construction time and manpower.

Excellent performance: high compressive strength after curing, impermeability and crack resistance, high and low temperature resistance, and long service life.

Economical and practical: Low material loss, low construction and maintenance costs, wide applicability, and environmental friendliness.

Product Parameters

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

length (M) | 10--50 | / | |||

width (M) | 1--3 | / | |||

thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

fire protecting performance | B1 | GB 8624-2012 | |||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

Copper (total copper) (mg/L) | ≤100 | ||||

Zinc (total zinc) (mg/L) | ≤100 | ||||

Cadmium (total) (mg/L) | ≤1 | ||||

Lead (total lead) (mg/L) | ≤5 | ||||

Total chromium (mg/L) | ≤15 | ||||

Nickel (total nickel) | ≤5 | ||||

Arsenic (total) | ≤5 | ||||

Product Application

1.Water conservancy engineering field

In hydraulic engineering, cement blanket is an ideal material for anti-seepage and reinforcement. The lining can be used for irrigation channels in farmland, and its anti-seepage performance can effectively reduce water resource leakage and improve irrigation efficiency; In the anti-seepage treatment of small dams, laying cement blankets can quickly form a tight waterproof barrier to resist water flow erosion; For river regulation projects, it can be used for slope protection, preventing soil erosion, and is easy to construct, adapting to the complex terrain of rivers.

2.Road and infrastructure engineering

In road engineering, cement blankets can be used for temporary road paving, especially during emergency repairs or construction in remote areas, which can quickly form a road surface with a certain strength to ensure vehicle traffic; In roadbed reinforcement, laying cement blankets can enhance the stability of the roadbed and reduce settlement; In addition, in the backfill layer protection after municipal pipeline laying, it can effectively protect the pipeline from external pressure damage and reduce maintenance costs in the later stage.

3.Emergency and rescue engineering

Cement blankets play an important role in emergency repairs after natural disasters such as floods and earthquakes. It can quickly build temporary flood embankments to prevent the spread of floods; In the temporary repair of damaged roads and bridges, it can quickly provide supporting structures to ensure smooth rescue channels; For ruptured reservoirs, water pipelines, etc., laying cement blankets can quickly stop water, reduce resource waste, and minimize the risk of secondary disasters.

Cement blankets have excellent application performance in various engineering fields such as water conservancy, roads, emergency rescue, etc. due to their convenient construction, stable performance, and wide applicability. It can not only improve engineering efficiency and reduce costs, but also play a reliable protective and supporting role in various complex environments, providing efficient and practical solutions for various engineering constructions, demonstrating unique application value and broad application prospects.