Concrete Cloth

1.Rapid Construction:

Hardens upon contact with water, curing into a high-strength concrete layer within 24 hours, significantly reducing construction time. No on-site mixing or pouring required—simply lay and use.

2.Lightweight & Flexible:

Transportable in roll form, with a lightweight design , facilitating manual handling and construction in complex terrains. Can be cut and bent to fit irregular surfaces.

3.High Strength & Durability:

Achieves compressive strength exceeding 20MPa after curing, with excellent abrasion and erosion resistance, and a service life of over 10 years.

4.Eco-Friendly & Energy-Efficient:

Reduces material waste by over 90%, eliminates the need for formwork and heavy machinery, and lowers carbon emissions. Some products support vegetation growth, promoting ecological integration.

Product Introduction:

Concrete Cloth is a revolutionary flexible concrete-impregnated fabric that hardens upon hydration to form a thin, durable, and waterproof concrete layer. Combining the flexibility of textiles with the strength of concrete, it enables rapid installation without traditional mixing or pouring.

Material Characteristics

1.Composite Structure

The cement blanket is composed of a three-dimensional textile fiber framework (e.g., polyethylene or polypropylene) blended with a specially formulated dry concrete powder. A waterproof layer (e.g., PVC) is applied to the bottom to ensure that only the surface undergoes hydration upon contact with water, preventing the loss of internal materials.

2.Hydration Upon Water Contact

When exposed to water, the dry concrete powder reacts to form a high-strength concrete layer. The material remains malleable for adjustment within 2 hours and achieves 80% of its design strength within 24 hours, with a final compressive strength exceeding C40.

3.Physical Properties

Waterproof and Fireproof: After hardening, it forms a dense structure with excellent waterproof performance. The material is non-combustible and meets Class A fire resistance standards.

Strong Weather Resistance: It resists UV radiation, freeze-thaw cycles, and chemical corrosion, making it suitable for extreme environments.

Flexibility: Before hardening, it can be bent and cut to adapt to complex terrains; after hardening, it exhibits crack resistance and impact resistance.

Product Parameters:

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

| length (M) | 10--50 | / | |||

| width (M) | 1--3 | / | |||

| thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

| Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

| Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

| Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

| Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

| Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

| fire protecting performance | B1 | GB 8624-2012 | |||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

| Copper (total copper) (mg/L) | ≤100 | ||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||

| Cadmium (total) (mg/L) | ≤1 | ||||

| Lead (total lead) (mg/L) | ≤5 | ||||

| Total chromium (mg/L) | ≤15 | ||||

| Nickel (total nickel) | ≤5 | ||||

| Arsenic (total) | ≤5 | ||||

Product Applications:

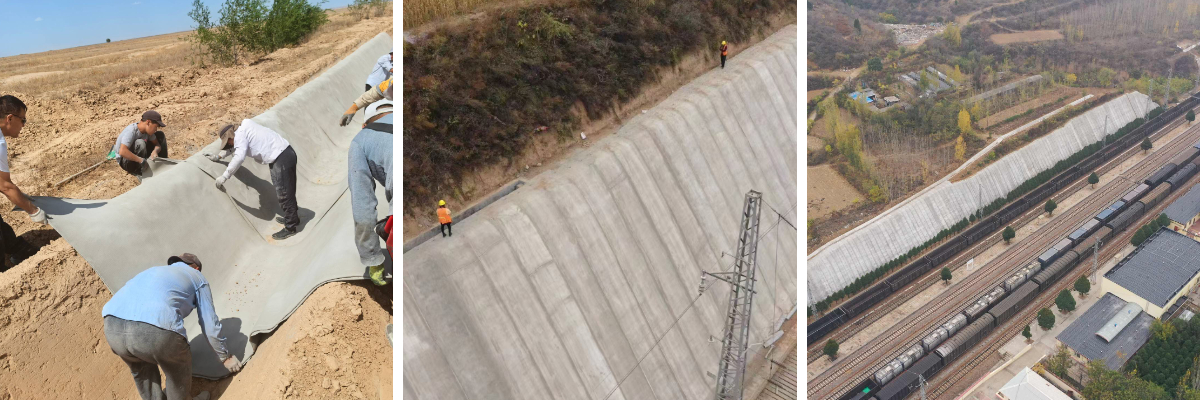

1. Water Conservancy & Drainage Engineering

Canal Lining: Rapid installation to prevent leakage and scouring.

Ditch Reinforcement: Suitable for farmland, roadside ditches, etc., with erosion resistance.

Embankment Slope Protection: Prevents soil erosion and enhances flood control capacity.

2. Slope Protection & Ecological Restoration

Soil/Rock Slope Reinforcement: Prevents landslides and adapts to complex terrains.

Mine Reclamation: Certain models support vegetation growth for ecological recovery.

Bare Ground Stabilization: Suppresses dust, ideal for temporary construction sites or desertification control.

3. Transportation & Infrastructure

Temporary/Emergency Roads: Quick deployment with 24-hour trafficability, suitable for disaster relief or military use.

Pipeline/Cable Protection: Forms a rigid protective layer against mechanical damage.

Bridge Pier Protection: Resists water flow erosion, extending structural lifespan.

4. Construction & Municipal Applications

Basement/Roof Waterproofing: Forms a seamless waterproof layer after curing.

Temporary Ground Hardening: Replaces concrete subgrades for exhibitions or event venues.

Chemical Plant/Landfill Seepage Control: Corrosion-resistant, prevents hazardous liquid leakage.