Concrete Cloth for Sale

1. Convenient and efficient installation: Adopting a roll shaped design, there is no need for large equipment during transportation, and a single person can operate it; It can be initially cured within 1-2 hours after encountering water, and can reach its strength within 24 hours.

2. Green, energy-saving and low-carbon: Made with environmentally friendly raw materials, it will not produce dust and noise pollution during the construction process, and has minimal impact on the surrounding environment; At the same time, the material utilization rate is close to 100%, with no waste, fully meeting the relevant standards for green buildings.

3. Excellent durability: Made of composite materials, its compressive strength can reach over 30MPa, and its tensile strength is three times that of ordinary concrete, which can effectively resist external impact.

4. Lower overall cost: The material itself is reasonably priced and does not require a large amount of labor and equipment investment during construction, which can reduce labor and machinery costs.

Products Introduction:

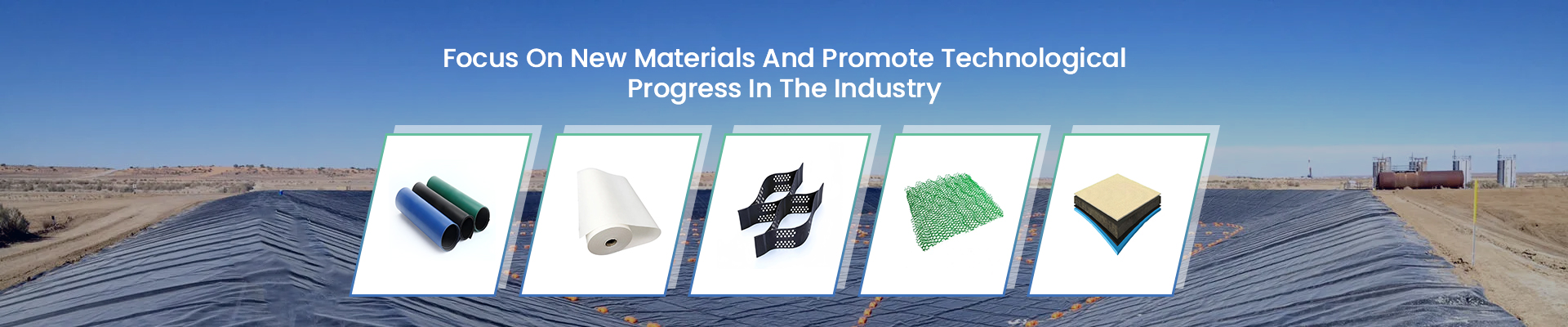

Concrete Cloth for Sale is a groundbreaking innovative product in the field of building materials. It breaks the traditional impression of concrete being rigid and cumbersome, and redefines the standards of rapid prototyping building materials through the cross-border integration of textile technology and building materials. From the appearance, it presents a uniform dark gray color with a delicate fabric texture on the surface. The single roll is packaged with waterproof material, and the weight is controlled within 20-50kg (adjustable according to customized needs). It can be easily transported by a single person, solving the problem of traditional concrete transportation relying on heavy vehicles.

As an upgraded solution to replace traditional concrete, it incorporates the flexibility of fabrics while retaining the high strength characteristics of concrete, transforming building materials from "rigid materials" to "flexible solutions for plasticity", especially suitable for modern engineering's demand for "efficiency, lightweight, and low threshold".

Product Features:

1. Minimalist operation: reduce the construction threshold to "zero professional barriers"

Traditional concrete construction requires workers to master professional skills such as proportioning, vibration, and maintenance, while cement blankets completely simplify this process: ordinary workers can operate independently after 30 minutes of training, without the need for construction engineers or concrete technicians to be present for guidance. When laying, the rolled material can be flexibly unfolded like a carpet, even for complex structures such as curved surfaces, slopes, corners (such as curved river slopes, circular pipe outer walls), seamless fitting can be achieved through cutting and splicing - the cutting tool only requires a regular art knife, with a flat cut and less prone to material scattering.

2. Stable performance: a dual guarantee of strength and durability

The cured cement blanket exhibits excellent mechanical properties: its compressive strength can reach 30-40 MPa (equivalent to the C30-C40 concrete standard), and it can withstand long-term crushing by heavy equipment such as cars and forklifts; The flexural strength reaches 5-8 MPa, which is 2-3 times that of ordinary concrete, and it is not easy to crack when the foundation slightly settles or temperature changes. This is due to the synergistic effect of fiber skeleton and cement - fibers disperse stress, while cement provides rigid support, forming a structure that combines rigidity and flexibility.

In terms of durability, it achieves multiple protections through raw material optimization: the added anti-seepage agent makes the water absorption rate less than 5%, which can be directly used in underwater environments (such as fish pond slope protection, small water tanks); The number of freeze-thaw cycles reaches over 300 times (far exceeding the standard of 200 times for ordinary concrete), and there will be no freeze-thaw cracking in winter even in extremely cold northern regions; At the same time, it has a certain degree of chemical corrosion resistance and can tolerate common acidic and alkaline substances in soil (stable within the pH range of 4-10). It is also applicable in scenarios such as agricultural irrigation channels and temporary industrial wastewater treatment tanks.

3. Time and material saving: Efficiency improvement throughout the entire cycle from construction to use

In terms of time cost, its advantages are particularly significant: traditional concrete needs to wait 7-14 days from mixing to being usable (standard curing cycle), while cement blankets can be put into basic use within 24 hours - taking a 100 square meter road repair as an example, traditional construction requires a team of 5 people to work for 3 days, while cement blankets only need 2 people to complete in 1 day, improving overall construction efficiency by more than 70%.

In terms of material utilization, it almost achieves "zero waste": traditional concrete usually has a material utilization rate of only about 80% due to transportation losses, vibration leakage, and other problems, while cement blankets are cut by area, and the remaining corner materials can be spliced and used, with an overall utilization rate of over 95%. Taking a 1000 square meter project as an example, material waste of over 50 square meters can be reduced, indirectly reducing material costs by 10% -15%.

4. Safety and environmental protection: low environmental load advantage throughout the entire lifecycle

From production to construction, the cement blanket always adheres to the concept of environmental protection: clean energy (such as photovoltaic power generation) is used in the production stage, and the amount of cement used in raw materials is reduced by 30% compared to traditional concrete (fiber skeleton replaces some of the cement used), reducing carbon dioxide emissions; During the construction phase, there is no need for large machinery such as concrete pump trucks and vibrators. The noise level is controlled below 50 decibels (equivalent to normal indoor conversation), and there is no dust flying (traditional concrete vibration can reach a dust concentration of over 2mg/m ³, while cement blanket construction is below 0.1mg/m ³). It is particularly suitable for environmentally sensitive areas such as residential areas and school surroundings.

Product Parameters:

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

length (M) | 10--50 | / | |||

width (M) | 1--3 | / | |||

thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

fire protecting performance | B1 | GB 8624-2012 | |||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

Copper (total copper) (mg/L) | ≤100 | ||||

Zinc (total zinc) (mg/L) | ≤100 | ||||

Cadmium (total) (mg/L) | ≤1 | ||||

Lead (total lead) (mg/L) | ≤5 | ||||

Total chromium (mg/L) | ≤15 | ||||

Nickel (total nickel) | ≤5 | ||||

Arsenic (total) | ≤5 | ||||

Product Applications:

1. Basic construction and civil engineering: making daily construction more efficient

In self built houses in rural areas, it can be directly used as an indoor floor cushion layer (instead of traditional cement mortar leveling). After laying, it can be cured by watering and tiles can be laid within 24 hours, avoiding the problems of hollowing and cracking in traditional leveling layers; In roof waterproofing engineering, it can be used as a waterproof protective layer, laid in accordance with the curvature of the roof, and solidified to form an overall waterproof structure, which is more resistant to puncture than membrane waterproofing. In pipeline construction, wrapping around the outer wall of PVC or PE pipes and spraying water for curing can quickly form a corrosion-resistant protective layer, especially suitable for pressure protection during underground pipeline backfilling.

2. Water conservancy and municipal engineering: anti-seepage reinforcement adapted to complex terrain

Small river slope protection is one of its core application scenarios: traditional stone masonry slope protection requires excavation and on-site masonry, with a construction period of 1-2 months. Cement blankets can be directly laid along the slope, conforming to the curvature of the riverbed, and after solidification, form an anti erosion layer (with a water flow erosion resistance strength of 5m/s). Due to its light weight (only 15-20kg per square meter), it will not increase the slope bearing pressure. It has replaced traditional solutions in irrigation channel renovation in many rural areas, and the construction period has been shortened from 30 days to 5 days.

In the municipal field, it can be used for reinforcing urban green belt retaining walls and rainwater wells - laid at the junction of inspection wells and road surfaces, which can avoid road settlement and cracking caused by vehicle crushing; It can also be used as a rapid prototyping material for road curbstones, which can be laid according to the design shape and cured to form neat curbstone lines without the need for templates.

3. Emergency and Outdoor Scenarios: Instant Solutions for Rapid Response

In emergency rescue, it is the best embodiment of "time is life": the temporary channel repair after an earthquake can be directly laid on the collapsed road surface, and after watering, it can be used for rescue vehicles to pass through within 2 hours; Reinforce the dam after the flood, lay and fix it along the inner side of the dam, and form an anti-seepage reinforcement layer after solidification to prevent pipe surge infiltration. In outdoor settings, camping sites can be used to build temporary parking grounds, which can be paved and solidified to solve the problem of muddy conditions in rainy days; As an irrigation canal lining in the farm, it is laid in accordance with the shape of the land to achieve low-cost anti-seepage (the construction cost per meter of canal is 40% lower than traditional concrete).

4. Industrial and special scenarios: meeting high-intensity and customized needs

When repairing the factory workshop floor, in response to local damage caused by long-term equipment compaction, corresponding sizes can be cut and laid. After solidification, it forms a whole with the original floor, and the compressive strength meets the long-term traffic requirements of forklifts (less than 5 tons); The unloading area of the warehouse can be used as a ground wear-resistant layer, laid on top of the original cement ground, to enhance the surface's wear resistance (the wear resistance coefficient is twice higher than that of ordinary cement ground). In mine restoration, it can be laid along the slope of the mine and solidified to form a stable protective layer. At the same time, its breathability (which still retains small pores after solidification) is utilized to provide a foundation for later vegetation restoration. This "slope stabilization first, followed by greening" model has been applied in multiple ecological restoration projects.

From a technical perspective, it achieves a perfect balance between flexible construction and rigid performance through a composite structure of "fiber skeleton+quick setting cement"; From the perspective of application value, whether it is improving the efficiency of daily buildings, optimizing the cost of municipal engineering, or responding quickly to emergency scenarios, it can solve practical pain points with the core advantage of "reducing costs by more than 30% and speeding up by more than 70%"; From the perspective of environmental protection, the low energy consumption and low emissions characteristics throughout the entire lifecycle are in line with the global trend of green building development.

For the construction party, it means less labor input and shorter construction period; For homeowners, it represents lower overall costs and more reliable engineering quality; For the environment, it is a friendly choice for reducing pollution and recycling. Whether you are a professional engineering team, an individual builder, or an organization in need of emergency solutions, Concrete Cloth can become the optimal solution in building material selection with its "simple, efficient, and reliable" characteristics, redefining the construction experience of modern engineering.