Concrete Canvas cc5

1. Easy and fast construction

Laying, fixing, and watering can be completed manually without the need for mixing, vibration, or large machinery.

2. Low maintenance costs

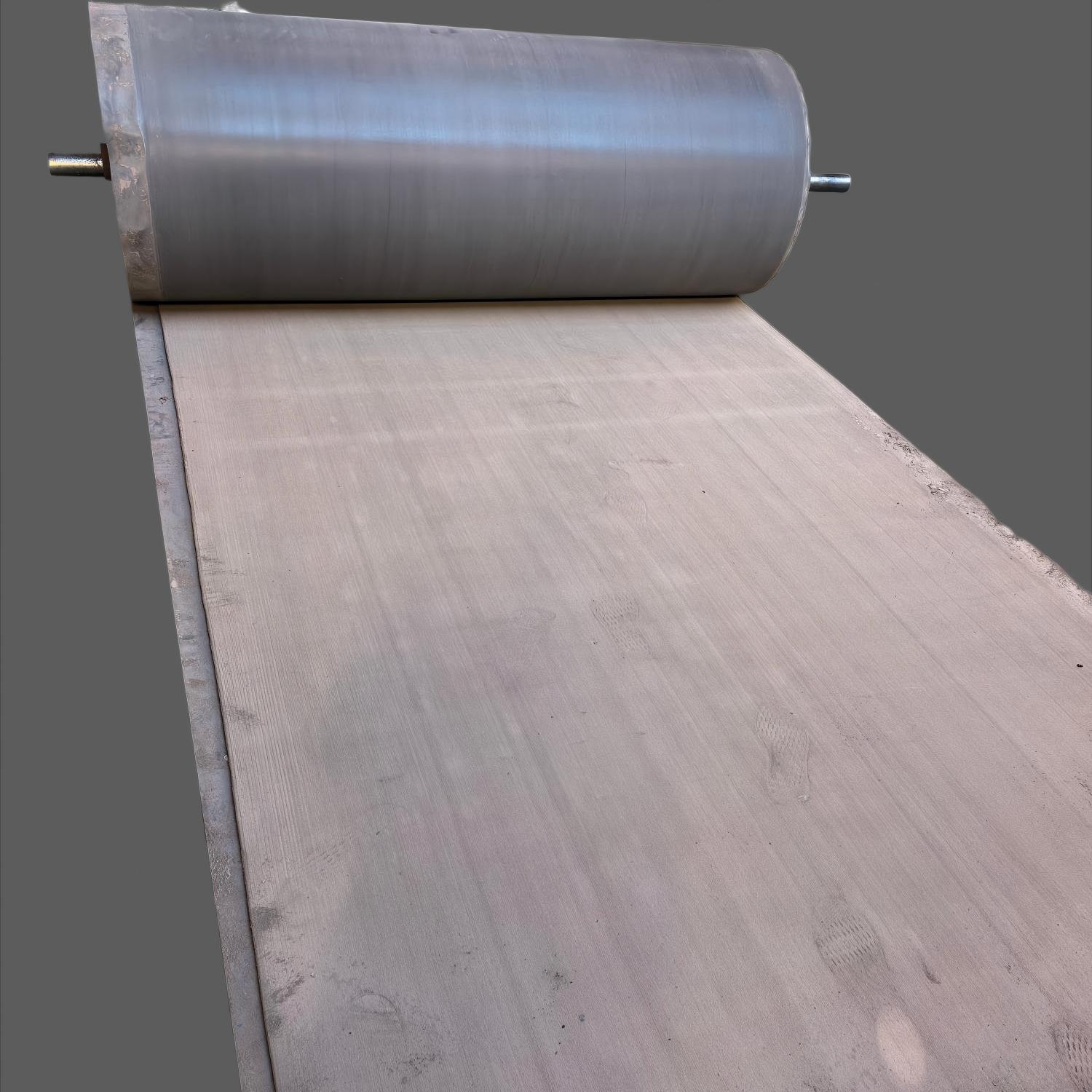

The surface is wear-resistant and dirt resistant, easy to clean and maintain, and can be extended in life by painting cement mortar after expiration. Excellent crack resistance, fiber structure absorbs impact energy, reducing the risk of cracking.

3. Significant economic viability

The material cost is lower than traditional concrete, and the comprehensive construction cost is reduced by 30% -50%. Rapid hardening shortens the construction period and reduces labor and equipment rental costs.

Product Introduction:

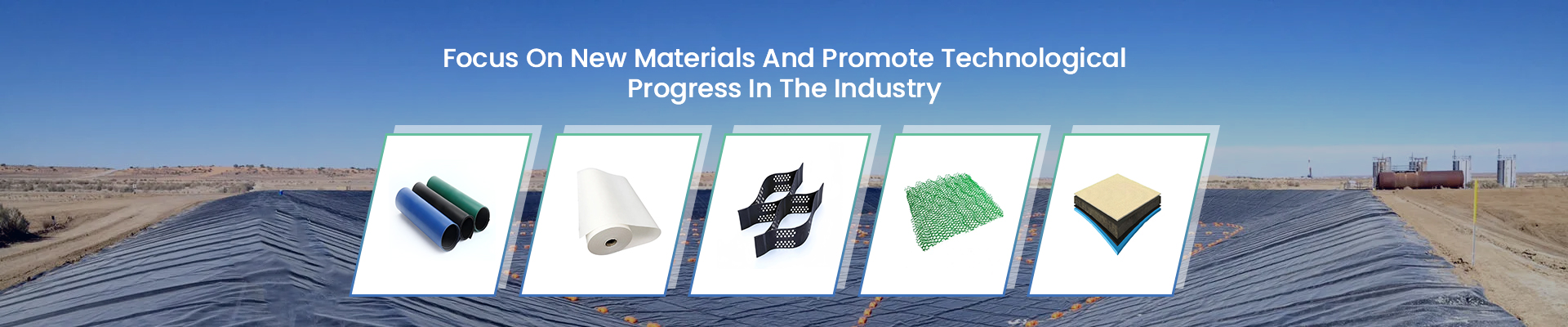

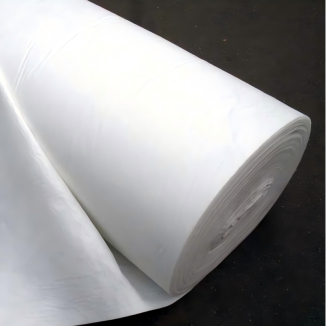

Concrete Canvas cc5 is flexible composite material impregnated with dry mixed cement powder. Its core structure is composed of a three-dimensional fiber frame combined with impermeable concrete powder. After encountering water, cement undergoes hydration reaction and hardens to form a waterproof, fireproof, and durable thin layer concrete structure with a thickness of only 5-13mm. The bottom layer is usually covered with polyvinyl chloride (PVC) or polyethylene (PE) anti-seepage film to further enhance the anti-seepage performance.

characteristic

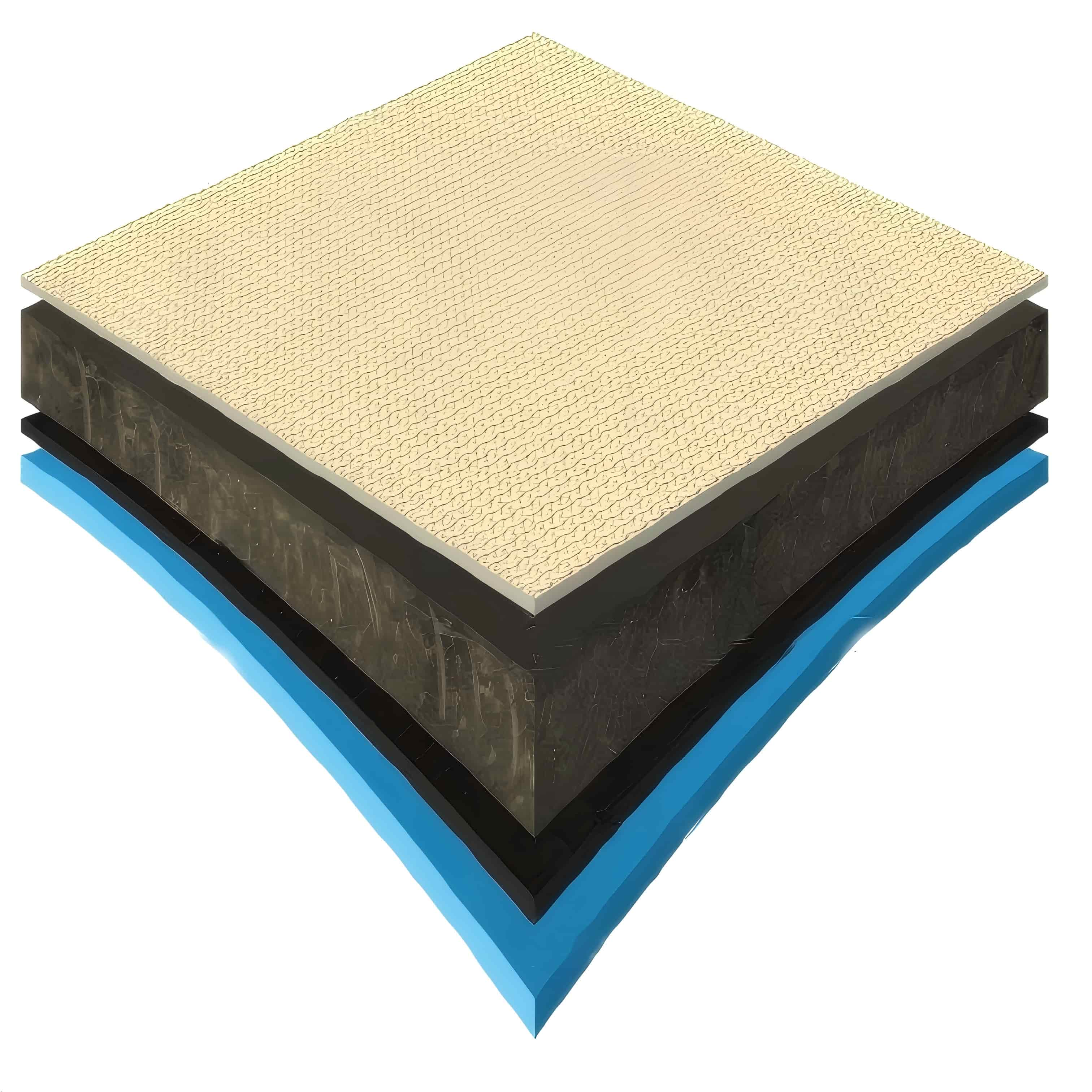

1. Flexible and Curlable

Cement blankets can be rolled up like carpets, making them easy to manually transport and store, especially suitable for construction in remote mountainous areas or areas with inconvenient transportation.

Good drape, able to tightly fit complex shapes (such as double curved surfaces, grooves), and even vertically suspend for use.

2. Rapid hardening and high strength

The shape can be adjusted within 2 hours after watering, and it will harden to 80% strength within 24 hours, with a final strength equivalent to traditional concrete.

High compressive strength, able to effectively resist wear, impact, and chemical corrosion, with a service life of over 10 years.

3. Multi functional protection performance

Waterproof and Fireproof: The bottom anti-seepage membrane prevents moisture infiltration, the material itself does not support combustion, is flame retardant, and emits less smoke.

Strong weather resistance: UV resistant, frost resistant, weather resistant, and adaptable to extreme weather conditions.

Sound insulation and noise reduction: The dense surface structure can effectively isolate noise and improve environmental comfort.

4. Environmental protection and low-carbon

The production process has low energy consumption, reduces material usage by 90% compared to traditional concrete, and shortens the construction period by 60%.

Precision molding reduces waste and conforms to the concept of sustainable development.

Product Parameters:

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

length (M) | 10--50 | / | |||

width (M) | 1--3 | / | |||

thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

fire protecting performance | B1 | GB 8624-2012 | |||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

Copper (total copper) (mg/L) | ≤100 | ||||

Zinc (total zinc) (mg/L) | ≤100 | ||||

Cadmium (total) (mg/L) | ≤1 | ||||

Lead (total lead) (mg/L) | ≤5 | ||||

Total chromium (mg/L) | ≤15 | ||||

Nickel (total nickel) | ≤5 | ||||

Arsenic (total) | ≤5 | ||||

Product Applications:

1. Water conservancy engineering

Channel anti-seepage: used for lining irrigation channels and scenic lakes in farmland to prevent water leakage and protect water resources.

Slope protection reinforcement: Lay on the slopes of rivers, dams, and reservoirs to prevent soil erosion and pipe surges.

2. Transportation Engineering

Road repair: Quickly repair damaged road surfaces and reduce traffic interruption time.

Railway/highway slope protection: reinforce slopes to prevent landslides and erosion.

3. Agricultural field

Aquaculture: Lay the bottom of fish ponds to prevent water leakage and soil erosion.

Livestock breeding: Construct livestock activity areas that are wear-resistant and easy to clean.

4. Emergency disaster relief

Temporary shelter: Quickly build temporary housing or infrastructure after earthquakes or floods.

Emergency reinforcement: repair emergency projects such as dam breaks and breaches, and control the disaster situation against time.

5. Industry and Municipal Affairs

Power facilities: transformer foundation, cable trench lining, moisture-proof and anti-corrosion.

Landfill site: anti-seepage lining to prevent pollutants from seeping out.

Septic tank construction: waterproof and leak proof, extending service life.

6. Innovative applications

Vertical greening: As an alternative material to ecological bags, it supports plant growth while protecting slopes.

Artistic landscape: cut into specific shapes for creative design such as sculpture and floor decoration.

Cement blankets have become a disruptive alternative to traditional concrete due to their flexibility, rapid hardening, high strength, and environmental friendliness. From water conservancy engineering to emergency relief, from agricultural breeding to industrial protection, its application scenarios cover a wide range, especially suitable for projects with high requirements for efficiency, cost, and environmental protection. With the continuous advancement of technology, cement blankets are expected to demonstrate their unique value in more fields, promoting the transformation of the construction industry towards intelligence and greenness.