Concrete Canvas CC5

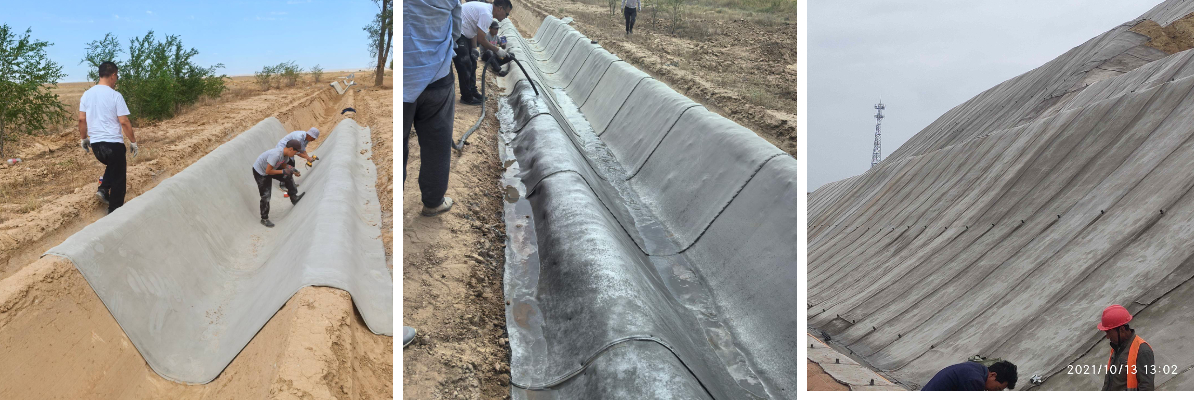

1.Convenient construction: It can be cut and laid like fabric, without the need for large construction equipment, saving labor and time costs.

2.Rapid solidification: After encountering water, cement quickly solidifies, forming a hard concrete structure in a short period of time and shortening the engineering cycle.

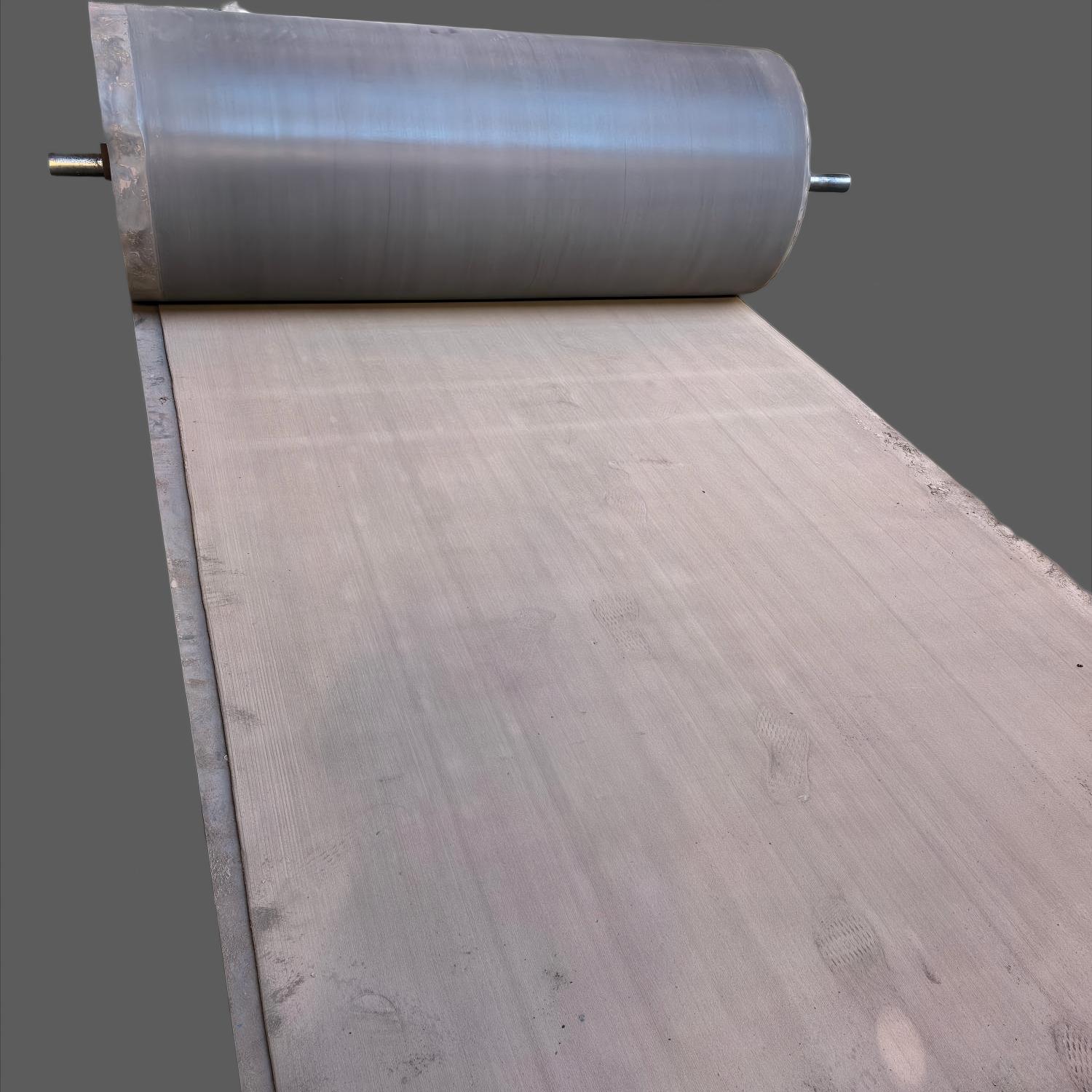

3.Convenient transportation: When not in use, it is rolled up, small in size, light in weight, and easy to transport and store.

4.Flexible application: It can adapt to various complex terrains and shapes, and is used in various scenarios such as ditches, slope protection, pipeline coverage, etc.

5.Waterproof and durable: The formed concrete structure has good waterproof performance, high strength, wear resistance, and long service life.

6.Environmental protection and energy conservation: reduce dust pollution caused by on-site cement mixing, achieve high material utilization, and reduce resource waste.

Products Introduction:

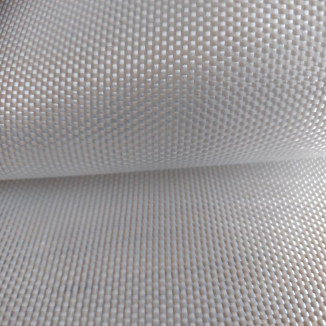

Concrete Canvas CC5 is a soft fabric with a surface impregnated with cement. When it comes into contact with water, it undergoes hydration reaction, forming a thin and durable layer of concrete.

1. High construction efficiency and low cost

Easy to lay: Watering and curing, no need to mix concrete, saving labor and equipment costs; Can be cut on-site and adapted to complex shapes.

2. Strong performance and wide adaptability

High strength and toughness: After hardening, it has strong load-bearing capacity and can withstand slight deformation of the foundation without cracking. It can be vertically suspended or covered with curved surfaces.

Waterproof, fireproof, and corrosion-resistant: The bottom waterproof layer prevents leakage, is resistant to chemical erosion, and is resistant to UV aging.

3. Multi functional and flexible application

Suitable for slope protection, pipeline protection, roof waterproofing, building crack repair and other scenarios, it can also provide sound insulation and heat insulation.

4. Environmental protection, energy conservation, low-carbon emission reduction

The material usage is 95% less than traditional concrete, reducing resource consumption; Construction has no dust or noise pollution, low alkali emissions, and minimal ecological impact.

Product Parameters:

surveillance project | DYSNT-A1 | DYSNT-B1 | DYSNT-C1 | Test basis | remarks |

length (M) | 10--50 | / | |||

width (M) | 1--3 | / | |||

thickness (mm) | 6mm/8mm/9mm/10mm/12mm/15mm/20mm | / | |||

Compressive strength (MPa) | ≧50 | ≧70 | ≧85 | GB/T17671-2021 | |

Flexural strength (MPa) | ≧13 | ≧18 | ≧22 | GB/T 7019-2014 | |

Flexural strength retention rate after freeze-thaw cycles (%) | ≧85% | ≧90% | ≧90% | GB/T 50082-2009 | The freezing and thawing cycle from 50 to 200 times changed the indexes accordingly |

Water quality requirements for hydration | running water | Tap water, sea water | Tap water, seawater, sewage | / | |

Construction temperature conditions | · Construction above 0℃ | · Construction above-5℃ | · Construction above-5℃ | / | |

fire protecting performance | B1 | GB 8624-2012 | |||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||

Copper (total copper) (mg/L) | ≤100 | ||||

Zinc (total zinc) (mg/L) | ≤100 | ||||

Cadmium (total) (mg/L) | ≤1 | ||||

Lead (total lead) (mg/L) | ≤5 | ||||

Total chromium (mg/L) | ≤15 | ||||

Nickel (total nickel) | ≤5 | ||||

Arsenic (total) | ≤5 | ||||

Product Applications:

1.Easy transportation: The product is supplied in roll form, with a compact size and light weight. It can be loaded, unloaded, and transported by a single person without relying on large lifting equipment, greatly reducing transportation difficulty and costs. Whether in remote areas with inconvenient transportation or narrow construction sites, it can be easily delivered.

2.Fast laying: No complex on-site mixing process is required, and laying can be carried out directly. It can be applied to both freshwater and seawater environments. Within 2 hours after watering, its size and shape can still be flexibly adjusted according to construction needs, with strong construction flexibility; Within 24 hours, the intensity can reach 80% of the standard value, greatly reducing the construction period.

3.Fitting complex shapes: With excellent drape and flexibility, it can closely conform to various complex surface shapes of objects, even for special shapes such as single leaf and double curvature, it can be perfectly fitted. Ordinary hand tools can be used to cut or trim freely, meeting the needs of diverse construction scenarios.

4.Environmentally friendly and eco-friendly: Compared with traditional concrete, the amount of materials used is significantly reduced, which can be reduced by about 95%, reducing resource consumption; The alkali content is limited, the erosion rate is extremely low, and the impact on the local ecological environment is minimal, which is in line with the concept of green and environmentally friendly construction.

5.Excellent waterproof performance: With the addition of a waterproof layer on the bottom, the waterproof level can reach IPX8, which can effectively resist the infiltration of various water sources such as rainwater and groundwater. It is used for significant waterproof and anti-seepage effects in water conservancy and underground engineering.

6.Fire performance meets the standard: The fire performance meets the standard and can effectively delay the spread of fire in the event of a fire, ensuring the safety of personnel and property. It is suitable for places with strict requirements for fire prevention.

7.Long design lifespan: Under normal usage conditions, the design lifespan is up to 10 years, and it performs well in terms of resistance to wind and rain erosion, UV degradation, and chemical resistance. Even when exposed to outdoor environments for a long time, its performance remains stable and reliable.

In summary, cement blankets have demonstrated high practicality and cost-effectiveness in various engineering scenarios due to their multiple advantages such as convenient construction, superior performance, convenient transportation and storage, and environmental friendliness. They provide an efficient and flexible alternative to traditional concrete construction.